Lamination method of solar cell module and the solar cell module

A technology for solar cells and modules, applied in the direction of lamination, electrical components, lamination devices, etc., can solve the problems of low yield, uneven film distribution, overflow, etc., to improve yield, uniform stress, and avoid deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

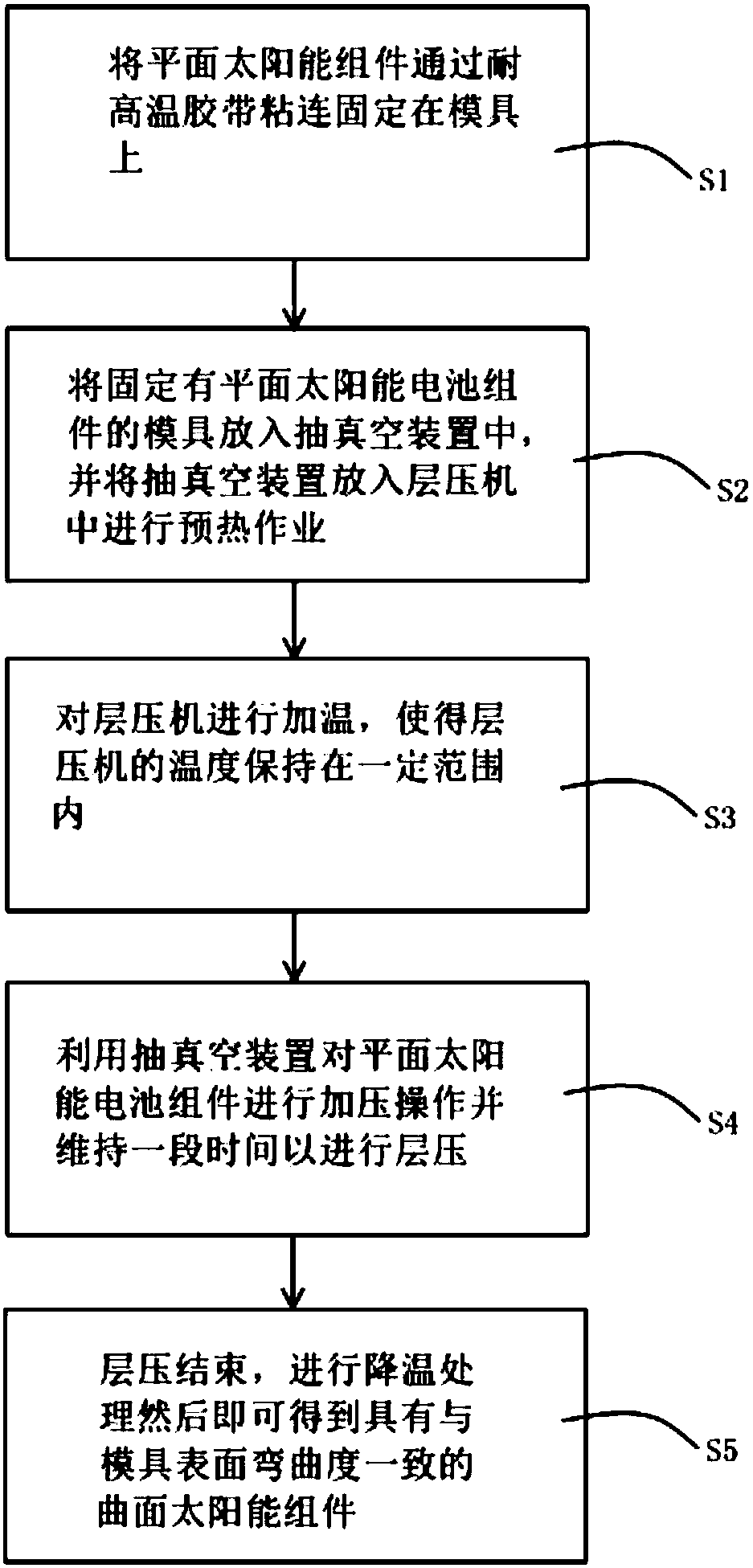

[0030] Such as figure 1 As shown, the present embodiment relates to a lamination method of a solar cell module, comprising the following steps:

[0031] S1. Fix the planar solar cell module on the mold by adhesive tape.

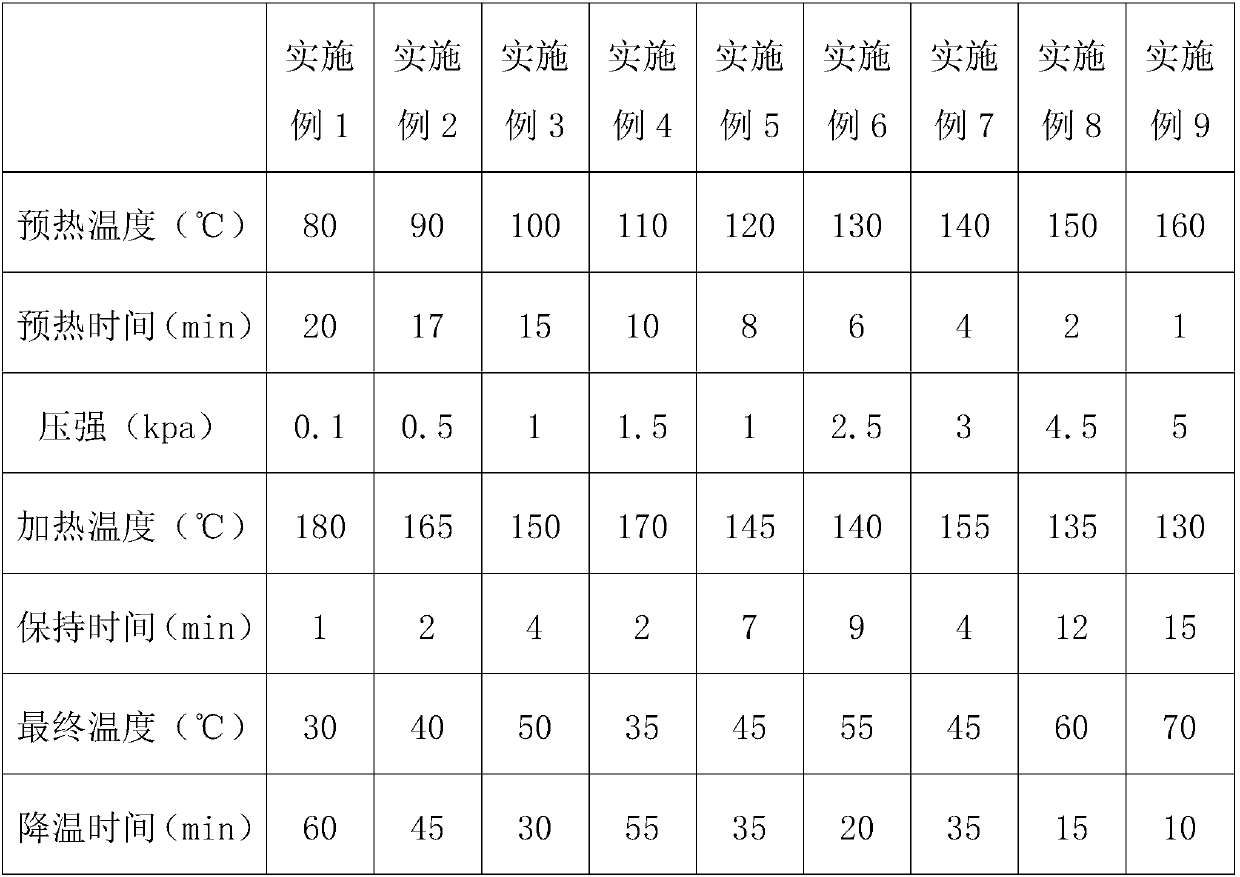

[0032] S2. Put the mold with the flat solar cell module fixed into the vacuum device, and then put the vacuum device into the cavity of the lamination device. In this embodiment, a lamination machine is selected, and then the vacuum device is preheated Operation, the preheating temperature and the preheating time of each embodiment are as shown in table 1.

[0033] S3. heat the laminator so that the temperature of the laminator remains within a certain range, and the temperature of the laminator is as shown in Table 1.

[0034] S4. Use a vacuum device to pressurize the planar solar cell assembly and maintain it for a period of time to perform lamination. The pressure and lamination time of the planar solar cell assembly are shown in Table 1.

[0035] S5. A...

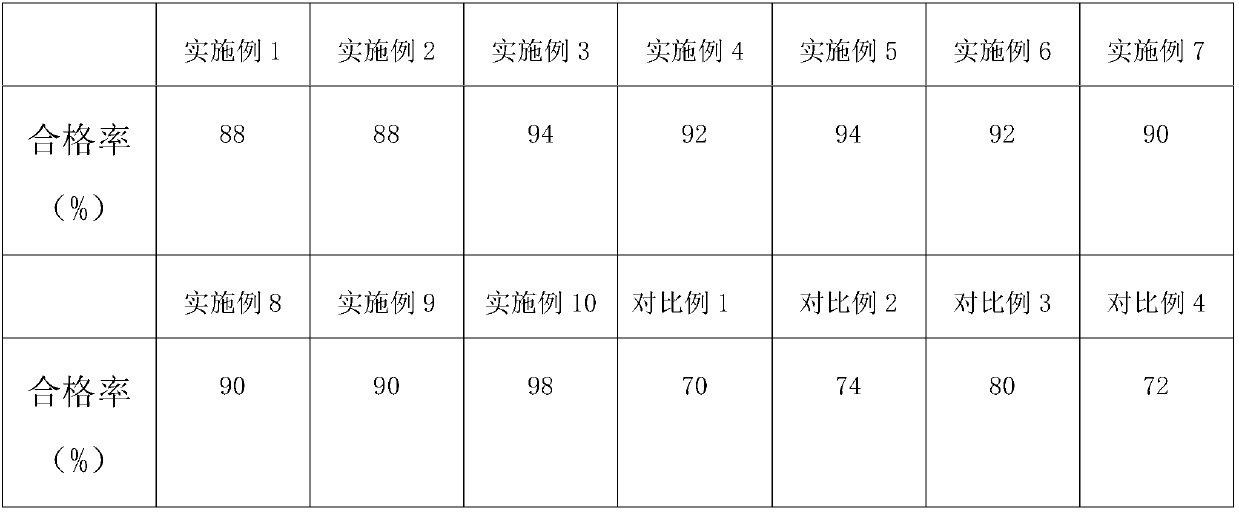

Embodiment 10

[0039] This embodiment relates to a lamination method of a solar cell module. The difference between this embodiment and Embodiment 5 is that in this embodiment, a first positioning hole is provided on the mold, and a second positioning hole is provided on the planar solar panel assembly. , the first positioning hole and the second positioning hole are equipped with positioning pins. When fixing the planar energy component, first align the first positioning hole and the second positioning hole, and then insert the positioning pins into the first positioning hole and the second positioning hole at the same time , and finally use adhesive tape to fix the planar solar cell module on the mold.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap