Bonding polymer, medical adhesive and preparation method of medical adhesive

A polymer and adhesive technology, applied in surgical adhesives, applications, medical science, etc., can solve the problem of weakening the bonding strength of the adhesive interface such as van der Waals force, weakening the chemical bond of the adhesive, and insufficient bonding strength, etc. problems, to achieve the effect of short reaction time, simplified follow-up processing, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

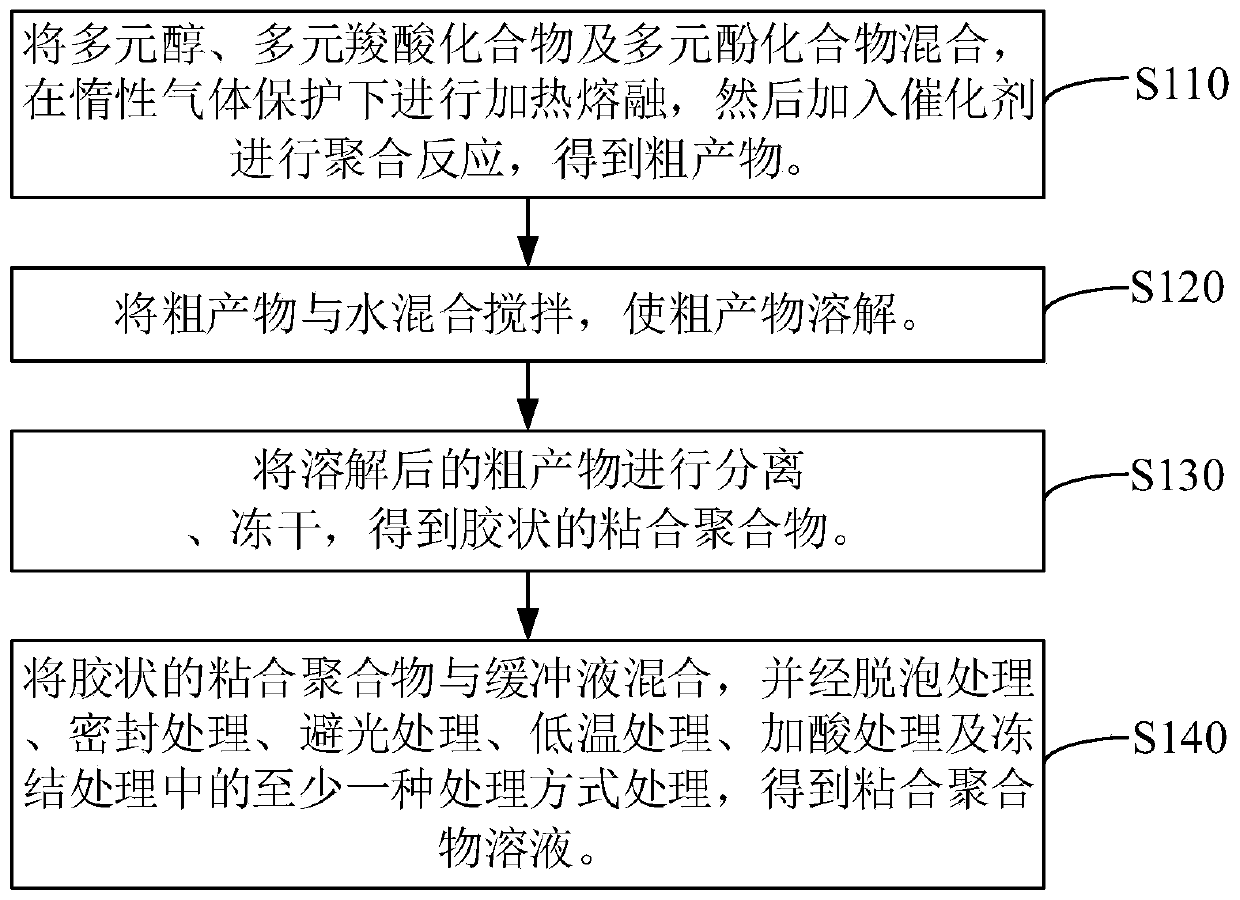

[0029] see figure 1 , the preparation method of the binding polymer of the present embodiment, comprises the steps:

[0030] Step S110: mixing polyhydric alcohol, polycarboxylic acid compound and polyphenol compound, heating and melting under the protection of an inert gas, and then adding a catalyst for polymerization reaction to obtain a crude product.

[0031] Wherein, the polyol includes at least one of alcohol compounds containing multiple hydroxyl groups and polymers containing multiple hydroxyl groups.

[0032] For example, the alcohol compound includes at least one of glycerin, xylitol and sorbitol. It can be understood that, in this embodiment, the alcohol compound also includes at least one of glycerol derivatives, xylitol derivatives and sorbitol derivatives.

[0033] The polymer is a linear or bulk alcohol polymer containing multiple hydroxyl groups. For example, the polymer includes at least one of polyethylene glycol, multi-armed polyethylene glycol, polyglyce...

Embodiment 1

[0075] The preparation process of the medical adhesive of the present embodiment is specifically as follows:

[0076] (1) Melt polymerization: add 3.72g citric acid, 6.69g polyethylene glycol (average molecular weight 400), 1.76g four-armed polyethylene glycol (average molecular weight 2000) and 1.00g dopamine hydrochloride simultaneously in the three-necked flask, nitrogen gas 15min. Place the above-mentioned three-neck flask in an oil bath that has been heated to 160°C, start stirring, and melt for 2 hours while stirring. After the reactant is completely melted, add an acidic catalyst, continue to stir the reaction until the end of the reaction, turn off the stirring and heating, stop nitrogen filling, and obtain the crude product.

[0077] (2) Dissolving: Pour 30 g of purified water into the three-necked flask after the reaction in step (1), and start stirring for 24 hours to dissolve the crude product.

[0078] (3) Dialysis: the dissolved crude product obtained in step (...

Embodiment 2

[0083] The preparation process of the medical adhesive of the present embodiment is specifically as follows:

[0084] (1) Melt polymerization: add 3.72g citric acid, 6.34g polyethylene glycol (average molecular weight 400), 3.52g four-armed polyethylene glycol (average molecular weight 2000) and 1.00g dopamine hydrochloride simultaneously in the there-necked flask, nitrogen gas After 15 minutes, put the above-mentioned three-neck flask in an oil bath that has been heated to 160°C, start stirring, and melt while stirring for 2 hours. After the reactant is completely melted, add an acidic catalyst, continue to stir the reaction until the end of the reaction, turn off the stirring and heating , stop filling nitrogen, and obtain crude product.

[0085] (2) Dissolving: Pour 30 g of purified water into the three-necked flask after the reaction in step (1), and start stirring for 24 hours to dissolve the crude product.

[0086] (3) Dialysis: the dissolved crude product obtained in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com