Amidoxime-based super-crosslinked microporous resin efficient uranium adsorbent and preparation method thereof

A microporous resin and amidoxime-based technology, which is applied in the field of amidoxime-based super-crosslinked microporous resin uranium adsorbent and its preparation, can solve the problems of low adsorption rate and saturated adsorption capacity, and achieve excellent adsorption capacity , high specific adsorption performance, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

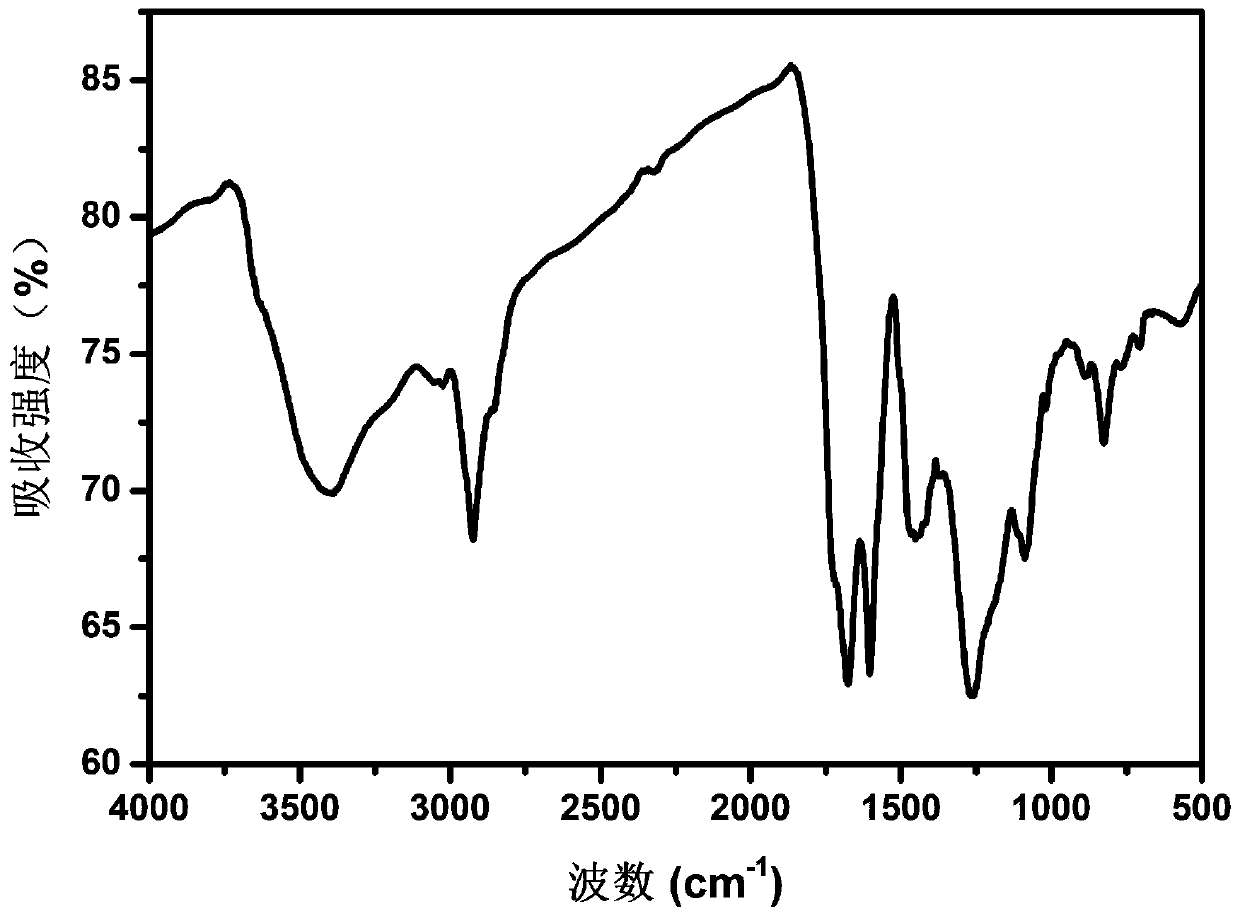

[0021] Specific implementation mode 1: The structural formula of the amidoxime-based super-crosslinked microporous resin high-efficiency uranium adsorbent in this embodiment is:

[0022]

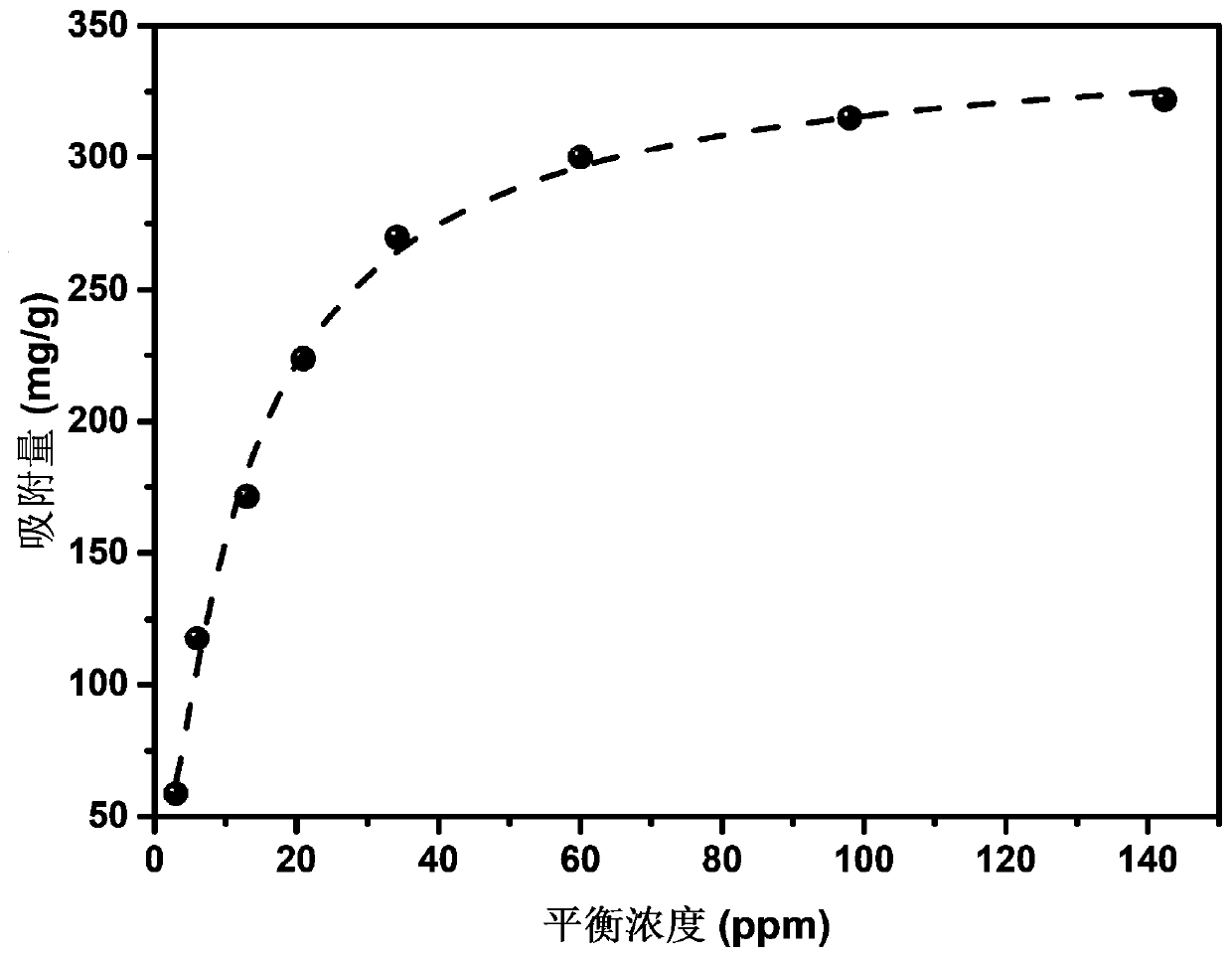

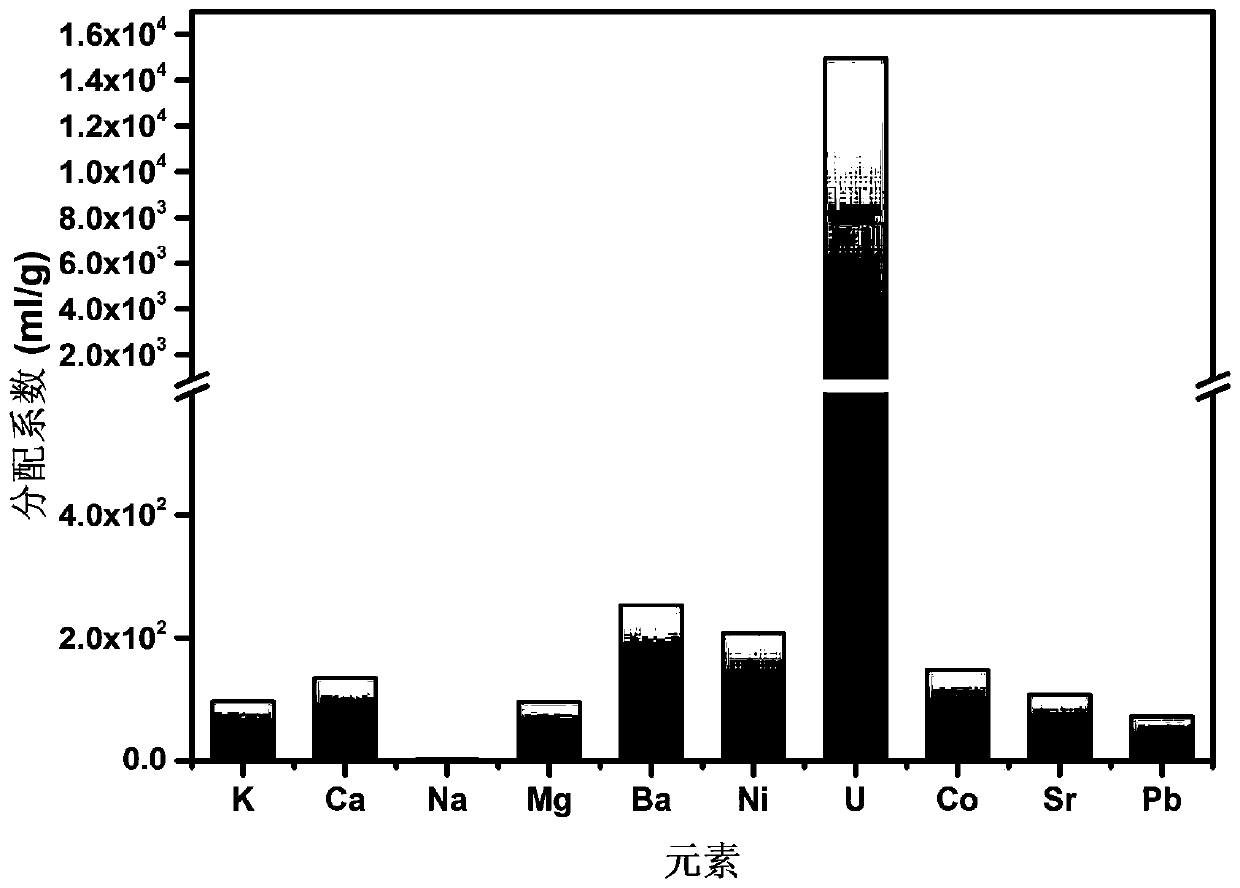

[0023] The adsorbent obtained in this embodiment combines the advantages of organic porous micromaterials and the excellent adsorption capacity of amidoxime functional groups for uranium, and has high adsorption rate, saturated adsorption capacity, adsorption rate and uranium ion selectivity. The uranium adsorbent has a significant effect on the concentration C 0 The adsorption rate of uranium ions in the uranium solution of =100ppm and pH=6 can reach more than 90%. Due to the specific recognition and adsorption of amidoxime groups on uranium ions, under the condition of 30°C, the saturated adsorption capacity of the uranium adsorbent is 20 times that of the microporous resin without amidoxime. Due to the existence of a large number of micropores in the uranium adsorbent, the uranium ion...

specific Embodiment approach 2

[0024] Specific embodiment two: the preparation method of amidoxime-based hypercrosslinked microporous resin high-efficiency uranium adsorbent in this embodiment is carried out according to the following steps:

[0025] One, take styrene and divinylbenzene as raw material synthesis polystyrene-divinylbenzene copolymer as resin matrix; Select polystyrene-divinylbenzene copolymer as resin matrix, this matrix contains a large amount of benzene rings, is follow-up The hypercrosslinking reaction provides the basis, and the matrix has good thermodynamic and chemical stability, which enables the material to maintain stable performance under harsh seawater conditions.

[0026] 2. Chloromethylate the resin matrix obtained in step 1 to obtain chloromethylated resin; methyl chloride is a lively functional group, which is easy to leave, making methylene participate in various chemical reactions, such as electrophilic substitution reaction, hydrophilic Nuclear substitution reaction, etc., ...

specific Embodiment approach 3

[0031] Specific embodiment three: different from specific embodiment two: the synthetic method of polystyrene-divinylbenzene copolymer described in step one is: add styrene and divinylbenzene in the container, then add initiator and anhydrous Ethanol, react at 60-80°C for 10-24h, cool to room temperature, filter, extract and vacuum-dry the resulting polymer in sequence to obtain a polystyrene-divinylbenzene copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com