Aerogel buffer heat insulation pad for battery module

A technology of battery modules and aerogels, applied in electrical components, secondary batteries, circuits, etc., can solve problems such as damage to the system, pollution of automotive products, and erosion and drop of powder on the surface of products to achieve excellent heat insulation Performance, good adhesion, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

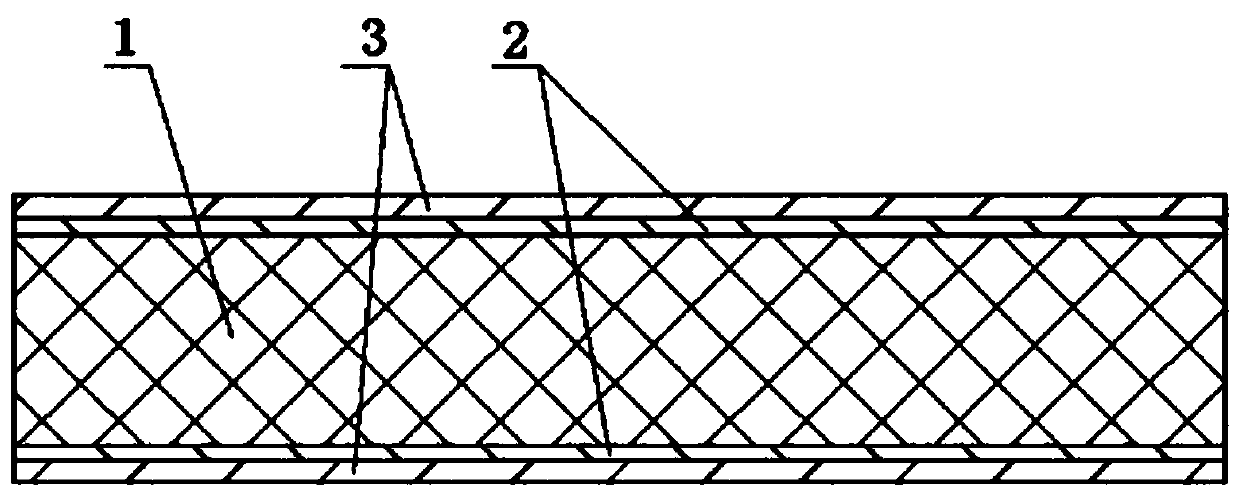

[0025] An airgel cushioning heat insulation pad for a battery module, comprising a needled felt, an airgel layer and a glue layer coated on the outer surface of the airgel layer, the opposite sides of the needled felt are respectively provided with a second An airgel layer and a second airgel layer, the glue layer envelops the entire outer surface of the airgel layer, wherein the thickness of the airgel layer is 0.1mm. The thickness of the glue layer is 0.01mm. The material of the airgel layer is silica airgel. The glue layer is mainly made of the following raw material components by weight: 0.05 parts of carbon powder, 1.3 parts of glass fiber powder, 0.6 parts of tributyl phosphate (flame retardant), 2 parts of phenolic resin glue, and α-cyano Acrylic instant adhesive (structural adhesive) 7 parts.

[0026] The battery module airgel buffer heat insulation pad is prepared by the following method:

[0027] Step S1, at a temperature of 30°C, mix the following raw material co...

Embodiment 2

[0034] An airgel cushioning heat insulation pad for a battery module, comprising a needled felt, an airgel layer and a glue layer coated on the outer surface of the airgel layer, the opposite sides of the needled felt are respectively provided with a second An airgel layer and a second airgel layer, the glue layer envelops the entire outer surface of the airgel layer, wherein the thickness of the airgel layer is 5 mm. The thickness of the glue layer is 0.3mm. The material of the airgel layer is aluminum oxide aerogel. The glue layer is mainly made of the following raw material components by weight: 0.2 parts of carbon powder, 1.8 parts of glass fiber powder, 2 parts of tris(dibromopropyl) phosphate (flame retardant), 4 parts of urea-formaldehyde resin glue, And epoxy acrylate glue (structural glue) 19 parts.

[0035] The battery module airgel buffer heat insulation pad is prepared by the following method:

[0036] Step S1, at a temperature of 60°C, mix the following raw mat...

Embodiment 3

[0043] An airgel cushioning heat insulation pad for a battery module, comprising a needled felt, an airgel layer and a glue layer coated on the outer surface of the airgel layer, the opposite sides of the needled felt are respectively provided with a second An airgel layer and a second airgel layer, the glue layer envelops the entire outer surface of the airgel layer, wherein the thickness of the airgel layer is 15mm. The thickness of the glue layer is 0.6mm. The material of the airgel layer is titanium dioxide airgel. The glue layer is mainly made of the following raw material components by weight: 1 part of carbon powder, 4 parts of glass fiber powder, 6 parts of magnesium hydroxide (flame retardant), 8 parts of high-temperature resistant epoxy glue, and ethylacrylic acid Ester adhesive (structural adhesive) 30 parts.

[0044] The battery module airgel buffer heat insulation pad is prepared by the following method:

[0045] Step S1, at a temperature of 80°C, mix the follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com