Ammonia-containing waste gas recycling device and method

A waste gas recovery and waste gas technology, applied in the direction of ammonium carbonate/acid carbonate, etc., can solve the problems that affect the economic benefits of waste water and waste gas of enterprises, secondary solid waste, and low value of ammonium sulfate, and achieve the realization of Recycling of resources, reduction of processing costs, and high recycling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

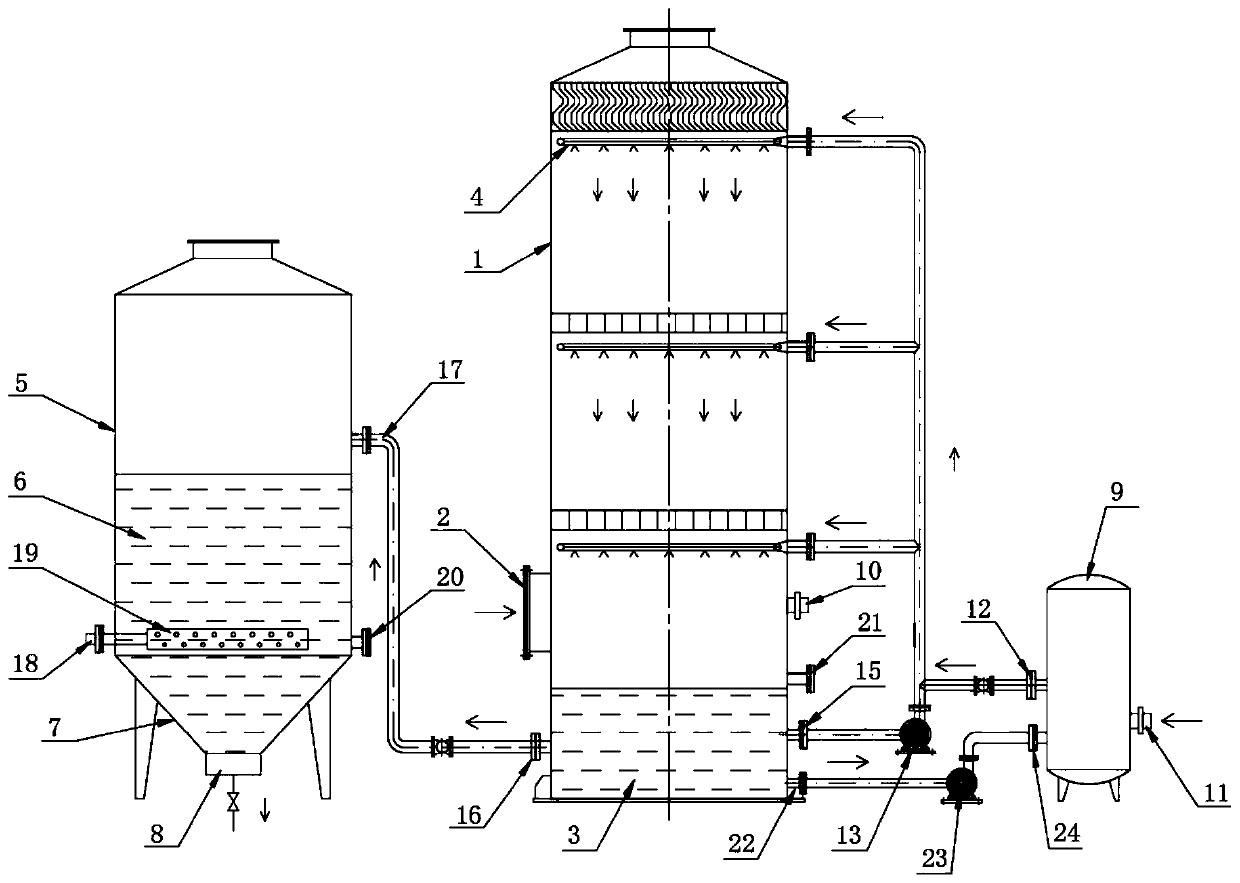

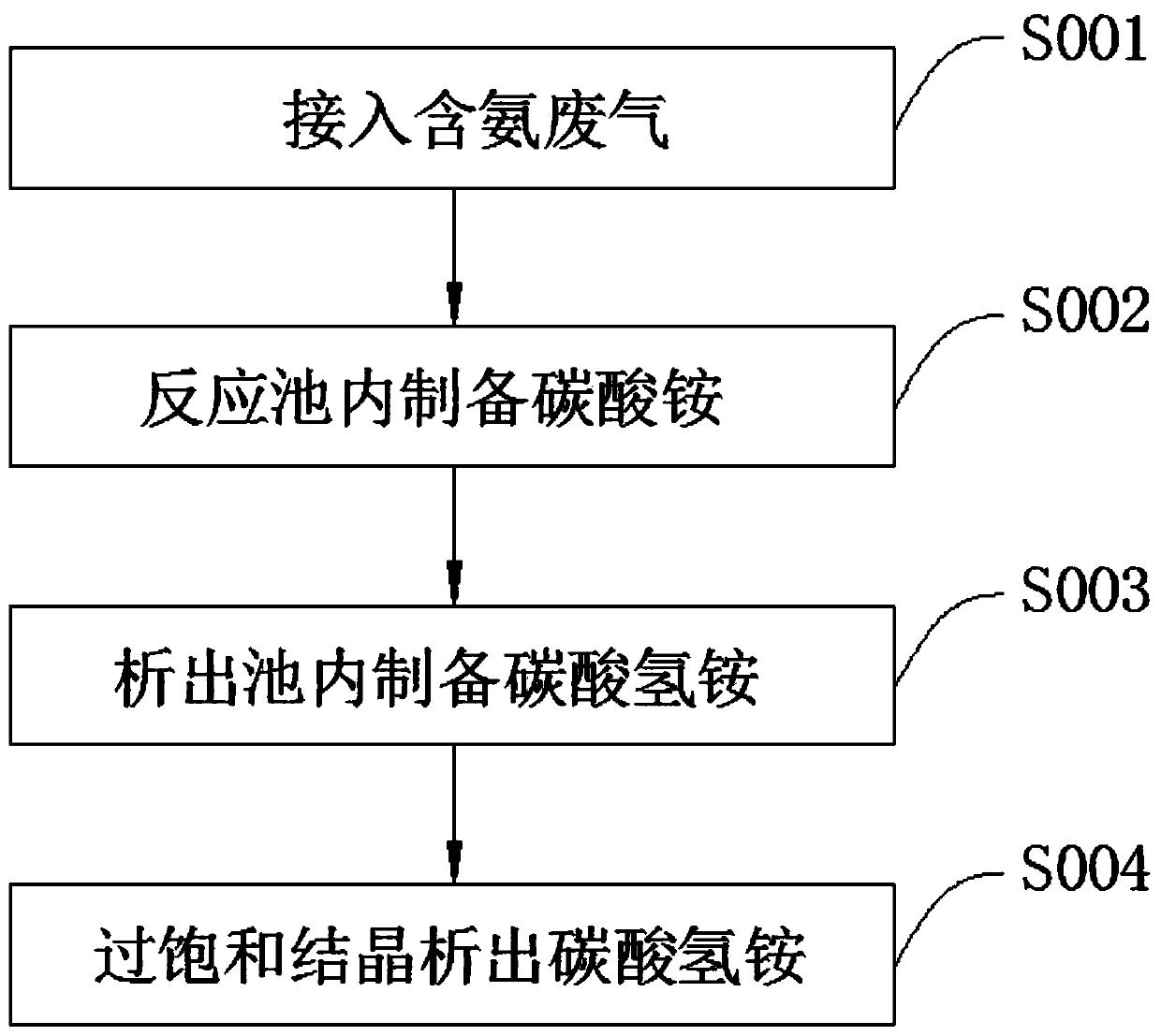

[0040] refer to figure 1 , image 3 and Figure 4 , the present embodiment provides a device and method for recycling waste gas containing ammonia. The device for recycling waste gas containing ammonia includes: a reaction tower group, a precipitation tower group, and a carbonic acid generation mechanism; the reaction tower group includes at least one reaction tower 1, and the reaction tower 1 is provided with an ammonia waste gas interface 2 near the lower end, and a reaction tank 3 for forming an ammonium carbonate solution is provided in the reaction tower 1, and the carbonic acid reacts with a sufficient amount of ammonia to form an ammonium carbonate solution; the reaction tower 1 is provided with multiple In the spray pipe 4 of spraying carbonic acid; Precipitating tower group comprises at least one precipitating tower 5, is provided with the precipitating pool 6 that is used to form supersaturated ammonium bicarbonate solution in the precipitating tower 5, and the bott...

Embodiment 2

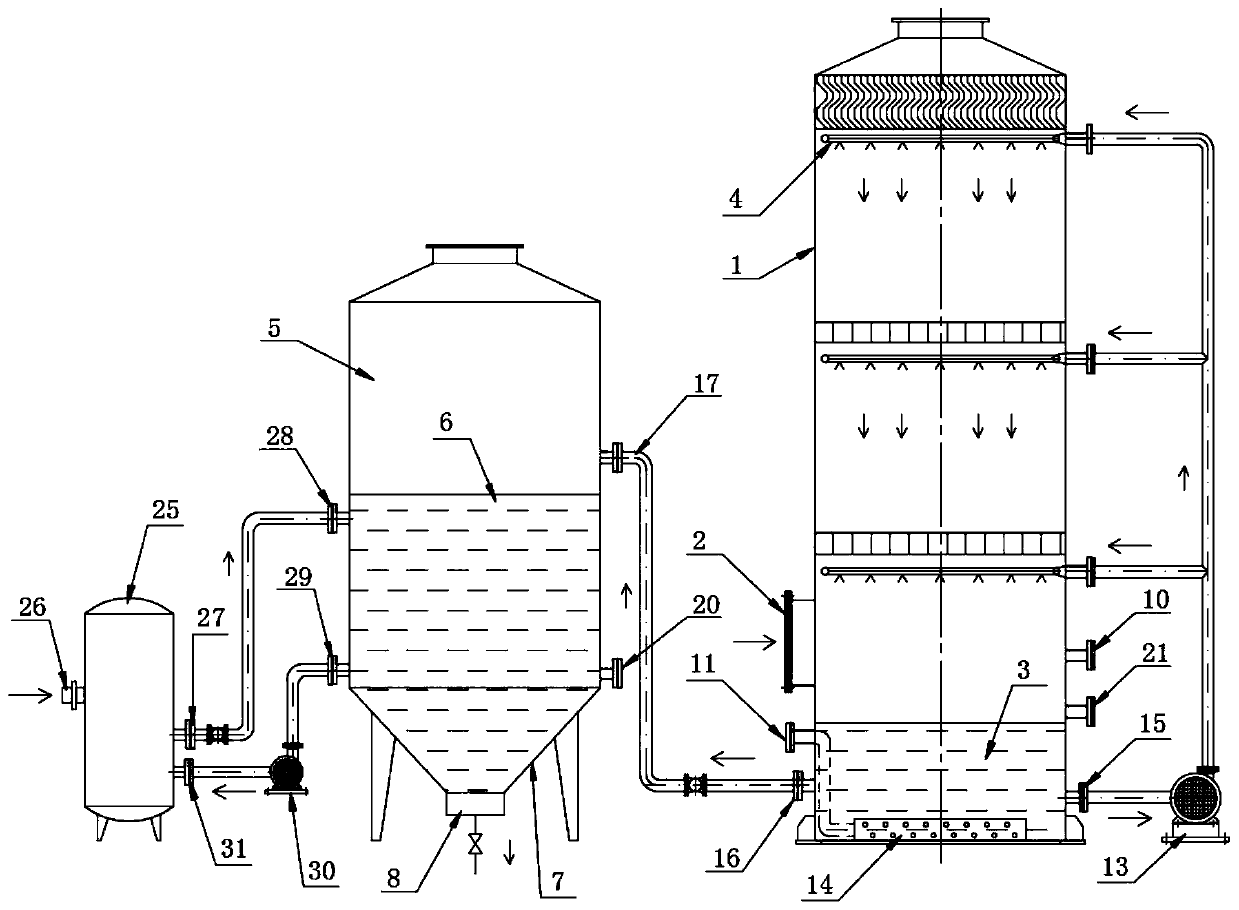

[0054] refer to figure 2 , the present embodiment ammonia-containing waste gas recovery and reuse device, the difference with the first embodiment is: the first carbonic acid mechanism of the present embodiment can also prepare carbonic acid by the aeration method, including the H 2 O water inlet 10 and the first CO 2 Air inlet 11, the bottom of reaction pool 3 is provided with the first CO 2 The first aeration pipe 14 connected to the air inlet 11, the circulation port 15 of the reaction tank 3 is connected to the spray pipe 4 through the circulation pump 13, the CO at the first aeration pipe 14 place 2 with H 2 H connected to O water inlet 10 2 O reacts to form carbonic acid. Wherein, the reaction tank 3 of the device is provided with a liquid level detector, and after the liquid level is lower than the set height, H 2 O water inlet 10 is opened and drained.

[0055] The second carbonic acid mechanism of the present embodiment can also prepare carbonic acid by a press...

Embodiment 3

[0060] refer to Figure 7 , the difference between this embodiment and Embodiment 1 and Embodiment 2 is that: the first carbonic acid mechanism prepares carbonic acid by pressurized gas-dissolving method, and the second carbonic acid mechanism prepares carbonic acid by pressurized gas-dissolved method; it is actually figure 1 9 parts of the first carbonation tank and figure 2 The combination of the second carbonic acid dissolving tank 25 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com