Landfill leachate treating process

A landfill leachate and treatment process technology, which is applied in the field of sewage treatment, can solve problems such as contradictions, and the difficulty of synchronously improving the effect of nitrogen and phosphorus removal, and achieve the effects of improving treatment capacity, solving the contradiction of mud age, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

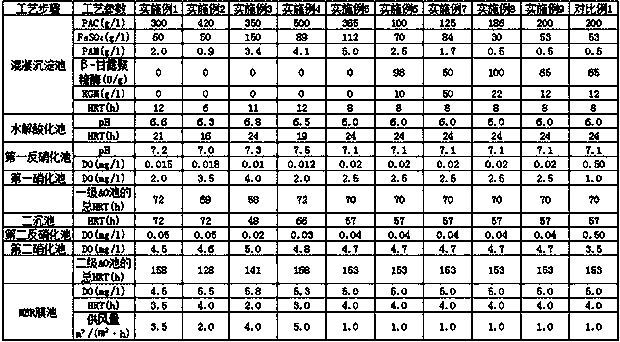

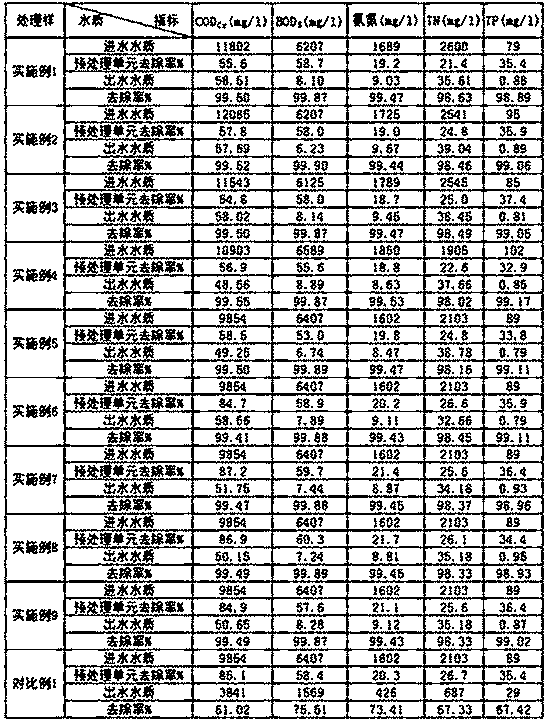

Embodiment 1

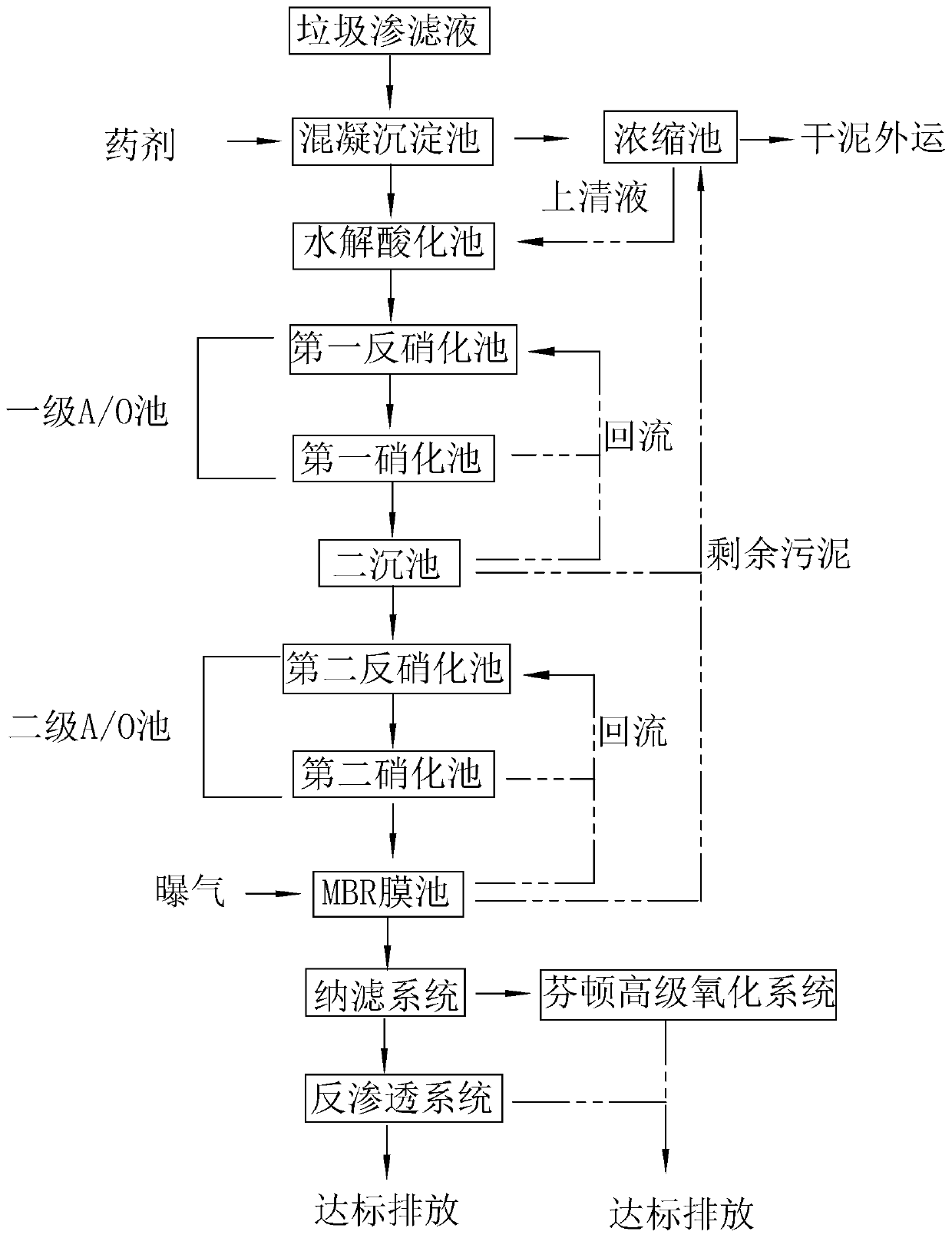

[0042] see figure 1 , using the treatment process of landfill leachate disclosed in the present invention to treat the landfill leachate of a landfill in Hangzhou, the COD of the landfill leachate Cr The concentration is 11802mg / l, BOD 5 The concentration is 6207mg / l, the concentration of ammonia nitrogen is 1689mg / l, the concentration of total nitrogen is 2600mg / l, the concentration of total phosphorus is 79mg / l, and the concentration of heavy metals is within the limit that does not affect biochemistry.

[0043] After the following process:

[0044] 1. Pretreatment unit: (1) Firstly, the above-mentioned landfill leachate is filtered by a grid to remove large particles and then discharged into the coagulation sedimentation tank, and chemicals are added to the leachate. The agent is polyaluminum chloride (PAC) as a flocculant 300g / l, ferrous sulfate 60g / l and 2.0g / l coagulant polyacrylamide (PAM) for coagulation and sedimentation, the hydraulic retention time HRT is 12h, the...

Embodiment 6

[0055](1) First, the above-mentioned landfill leachate is filtered out of large particles with a grid and then discharged into the coagulation sedimentation tank. The pH value of the coagulation sedimentation tank is adjusted to 6.0, and the temperature of the coagulation sedimentation tank is adjusted to 48 ° C. Dosing agent, the agent is polyaluminum chloride (PAC) 100g / l flocculant, ferrous sulfate 100g / l and 2.5g / l coagulant polyacrylamide (PAM) for coagulation and sedimentation, the hydraulic retention time HRT is After 12 hours, the sludge after coagulation and sedimentation is passed into the thickening tank and processed by plate and frame pressure filtration to obtain supernatant and sludge, and the sludge is dehydrated and dried.

Embodiment 7

[0057] (1) Firstly, the above-mentioned landfill leachate is filtered out of large particles with a grid and then discharged into the coagulation sedimentation tank. The pH value of the coagulation sedimentation tank is adjusted to 6.4, and the temperature of the coagulation sedimentation tank is adjusted to 30°C. Dosing agent, the agent is polyaluminum chloride (PAC) 125g / l flocculant, ferrous sulfate 84g / l and coagulant polyacrylamide (PAM) 1.7g / l for coagulation and sedimentation, the hydraulic retention time HRT is After 12 hours, the sludge after coagulation and sedimentation is passed into the thickening tank and processed by plate and frame pressure filtration to obtain supernatant and sludge, and the sludge is dehydrated and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com