Preparation method of phenoxyacetic acid

A technology of phenoxyacetic acid and chloroacetic acid, which is applied in the preparation of carboxylate, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of high production cost and low overall yield, so as to solve the problem of processing and improve the yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

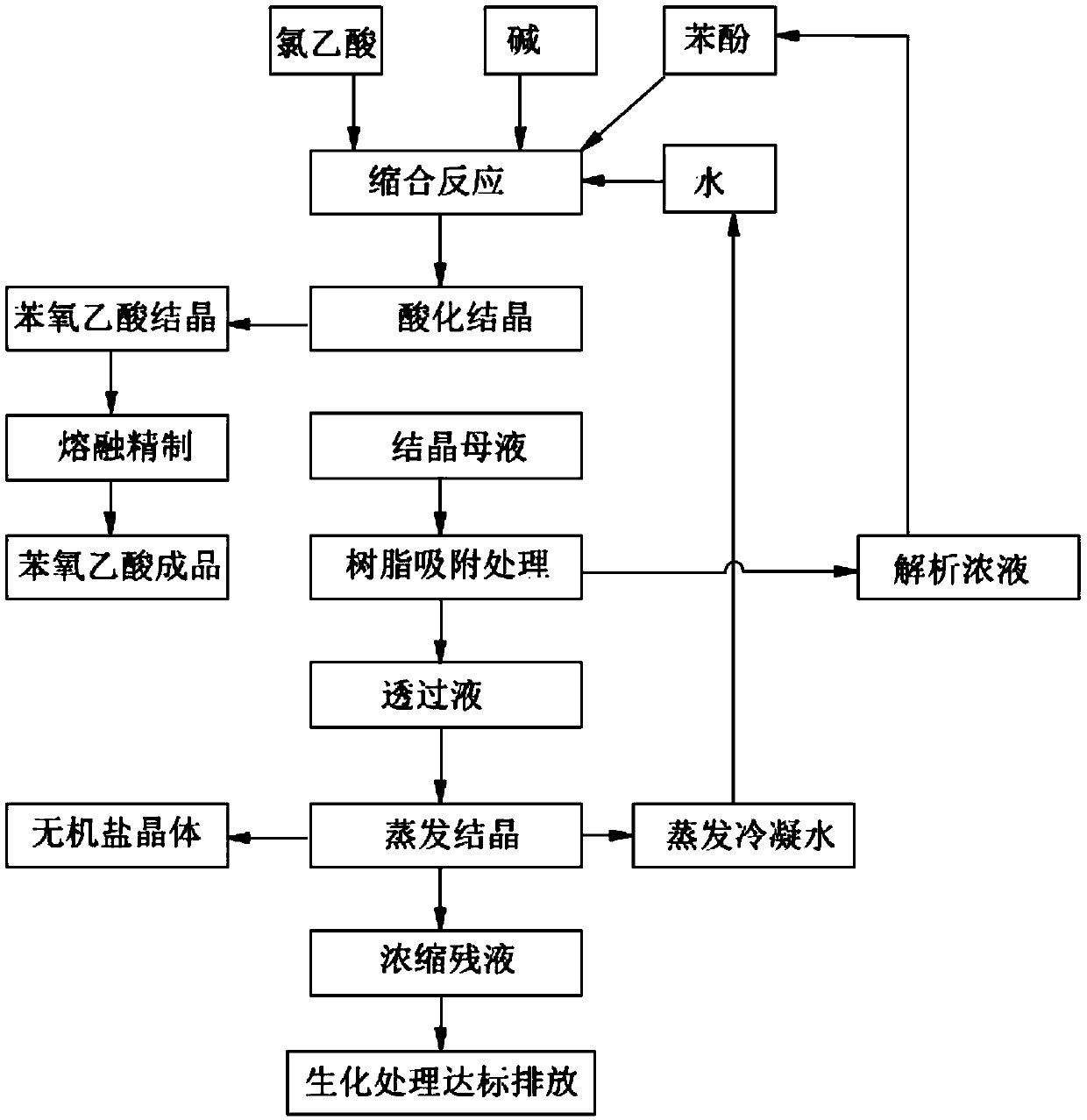

[0024] see figure 1 As shown, the embodiment of the present invention provides a kind of preparation method of phenoxyacetic acid, comprises the following operation steps:

[0025] Condensation reaction: mixing reaction raw materials including chloroacetic acid, phenol and alkali for condensation reaction to obtain reaction mother liquor;

[0026] Acidification and crystallization: Acidification and crystallization of the reaction mother liquor, separation of phenoxyacetic acid crystals and crystallization mother liquor;

[0027] Resin adsorption treatment: Adsorption resin is used to absorb the organic matter in the crystallization mother liquor, and the permeate contains inorganic salts;

[0028] Analyzing the dope: use lye to analyze the adsorption resin, and the obtained analytic dope is used as the reaction raw material for the condensation reaction.

[0029] According to the preparation method of phenoxyacetic acid provided by the present invention, the crystallization...

Embodiment 1

[0051] This embodiment is used to illustrate the preparation method of the phenoxyacetic acid disclosed in the present invention, comprising the following steps:

[0052] a. Material preparation: Add solid chloroacetic acid with a content of not less than 96% in the material preparation tank A, dissolve it in hot water at 50-60°C to a concentration of 50%, add solid alkali according to the molar ratio of chloroacetic acid:NaOH 1:1, and stir After 15 minutes, vinyl chloride material was obtained, which was kept warm for subsequent use. Add phenol with a content of not less than 98% in the material preparation tank B, replace the air with nitrogen, preheat the phenol to 70°C, add 30% (mass content) sodium hydroxide lye and analytical concentrated solution preheated to 75°C After stirring for 15 minutes, the phenol material was obtained, and the preparation was completed and kept warm. The molar ratio of phenol to sodium hydroxide was 1:1.05.

[0053] b. Condensation reaction: ...

Embodiment 2

[0058] This embodiment is used to illustrate the preparation method of the phenoxyacetic acid disclosed in the present invention, comprising the following steps:

[0059] a. Material preparation: Add solid chloroacetic acid with a content of not less than 96% in the material preparation tank A, and dissolve it with 50-60°C hot water (or material) to a concentration of 50%, according to the molar ratio of chloroacetic acid: liquid ammonia 1 : 1 was added, and after the addition was completed, the vinyl chloride material was obtained after stirring for 30 minutes, which was kept warm for subsequent use. Add phenol with a content of not less than 98% in the material preparation tank B, replace the air with nitrogen, preheat the phenol to 70°C, add potassium hydroxide lye preheated to 75°C and mix to achieve the content of phenol in the concentrated solution Equivalent, add pre-heated to 75 ℃ analytical concentrate. After stirring for 15 minutes, the phenol material was obtained,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com