Activated carbon material and preparation method and application thereof

The technology of activated carbon and granular activated carbon is applied in the field of activated carbon materials and the preparation of activated carbon materials, which can solve problems such as the diffusion of unfavorable pollutants, poor air circulation, health hazards of vehicle owners, etc., so as to improve the air quality in the vehicle, with low cost and simple and easy preparation method. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

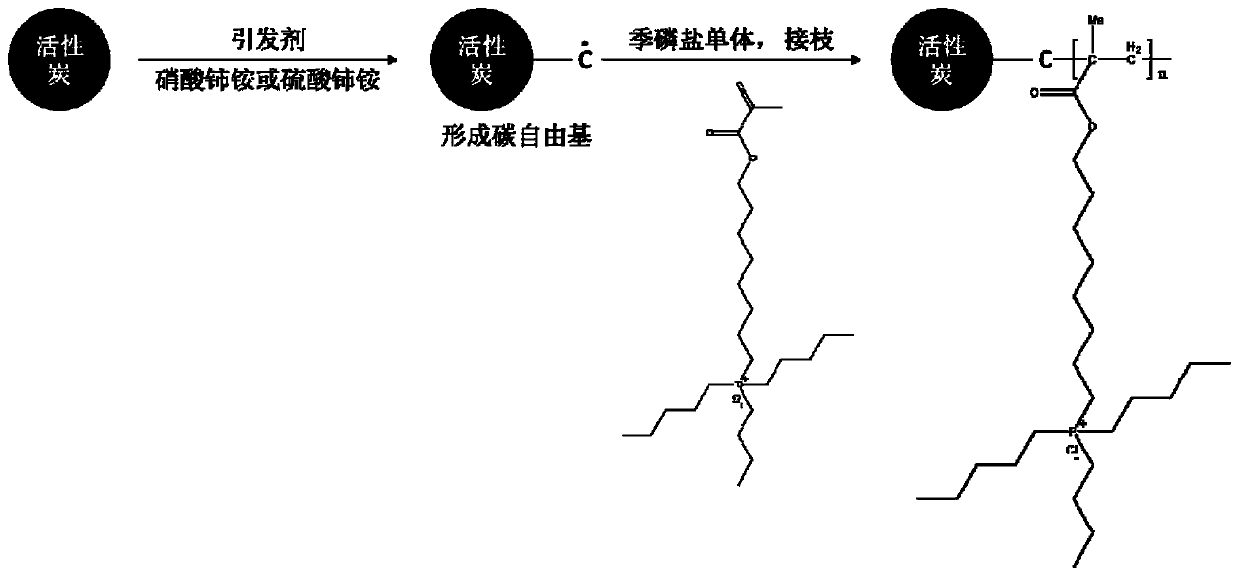

[0058] The invention provides a grafted quaternary phosphonium salt activated carbon material for a vehicle air conditioner filter and a preparation method thereof. The graft layer includes the following steps:

[0059] (1) Add quaternary phosphonium salt monomer material (methacryloyloxyheptyl-tributylphosphine chloride) into deionized water and stir evenly, so that the molar concentration of quaternary phosphonium salt monomer is 0.5mol / L, which is defined as solution A;

[0060] (2) adding ammonium cerium nitrate initiator in solution A, so that the molar concentration of ammonium cerium nitrate initiator is 0.02mol / L, which is defined as solution B;

[0061] (3) Add 10 g of activated carbon (rice husk charcoal) prepared by using rice husk as raw material in solution B and stir evenly, so that the mass ratio of activated carbon and solution is 1:6, which is defined as mixture C;

[0062] (4) in mixture C, fill with nitrogen and bubbling for 10min to exhaust the air, and t...

Embodiment 2

[0066] The invention provides a grafted quaternary phosphonium salt activated carbon material for a vehicle air conditioner filter and a preparation method thereof. The graft layer includes the following steps:

[0067] (1) Add quaternary phosphonium salt monomer material (methacryloyloxyheptyl-tributylphosphine chloride) into deionized water and stir evenly, so that the molar concentration of quaternary phosphonium salt monomer is 1.0mol / L, which is defined as solution A;

[0068] (2) adding ceric ammonium sulfate initiator to solution A, so that the molar concentration of ceric ammonium sulfate initiator is 0.04mol / L, which is defined as solution B;

[0069] (3) 10g of activated carbon (rice husk charcoal) prepared by using rice husk as a raw material is added into solution B and stirred evenly, so that the mass ratio of activated carbon and solution is 1:10, which is defined as mixture C;

[0070] (4) in mixture C, be filled with nitrogen and bubbling for 10min to exhaust...

Embodiment 3

[0074] The invention provides a grafted quaternary phosphonium salt activated carbon material for a vehicle air conditioner filter and a preparation method thereof. The graft layer includes the following steps:

[0075] (1) Add quaternary phosphonium salt monomer material (methacryloyloxyheptyl-tributylphosphine chloride) into deionized water and stir evenly, so that the molar concentration of quaternary phosphonium salt monomer is 1.0mol / L, which is defined as solution A;

[0076] (2) adding ammonium thiosulfate initiator in solution A, so that the molar concentration of ammonium thiosulfate initiator is 0.05mol / L, which is defined as solution B;

[0077] (3) in solution B, add the activated carbon (coconut shell carbon) 10g that utilizes coconut shell as raw material preparation and stir, make the mass ratio of activated carbon and solution be 1:20, be defined as mixture C;

[0078] (4) in mixture C, fill with nitrogen and bubbling for 10min to exhaust the air, and then se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com