Multi-point ground torch

A ground torch, multi-point technology, applied in the direction of combustion method, lighting and heating equipment, combustion type, etc., can solve the problems of incomplete combustion of heavy components, high consumption of natural gas, unfavorable environmental protection, etc., to reduce combustion pollution and reduce operation Cost, Effect of Flame Burning Completely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

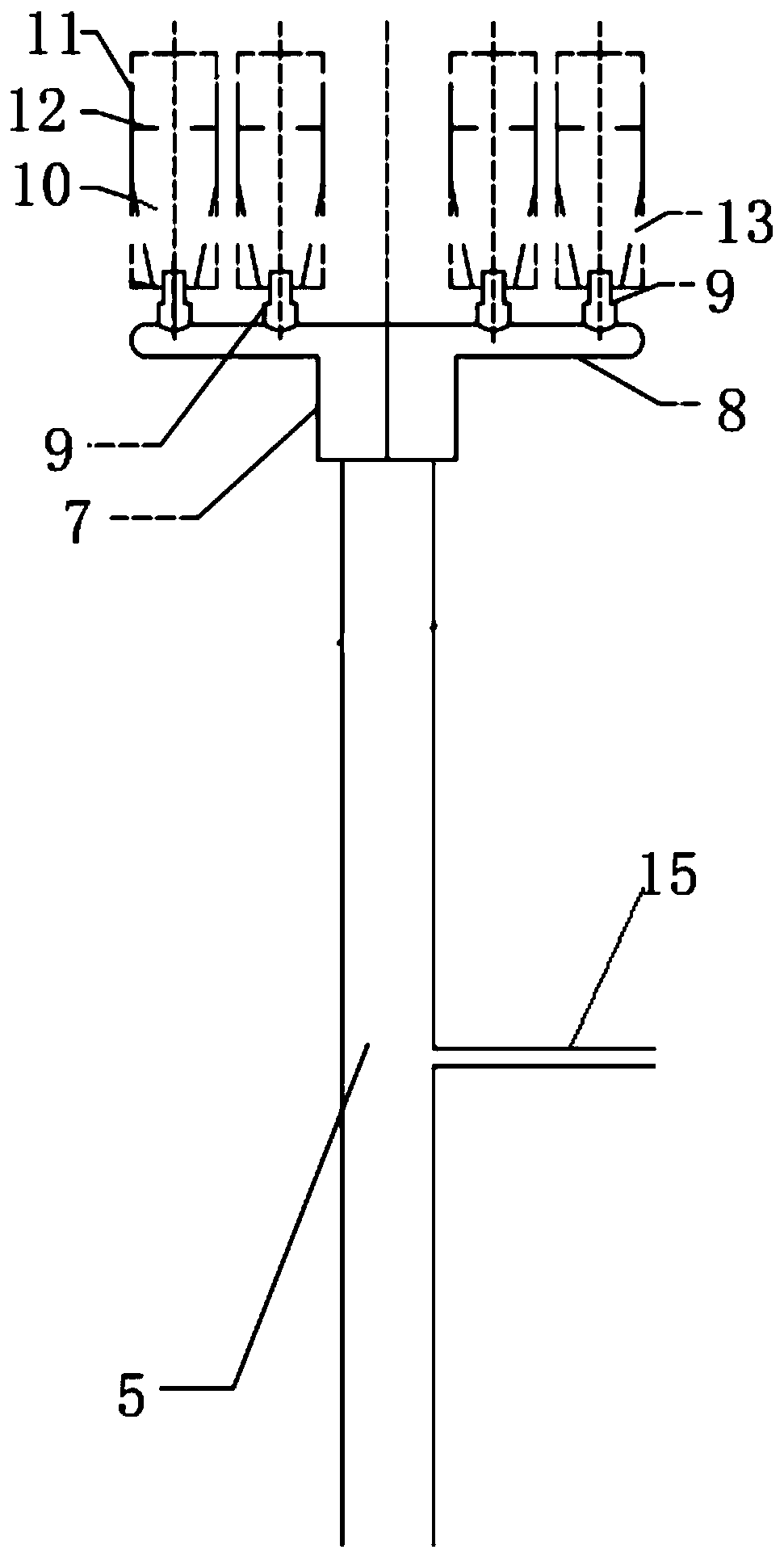

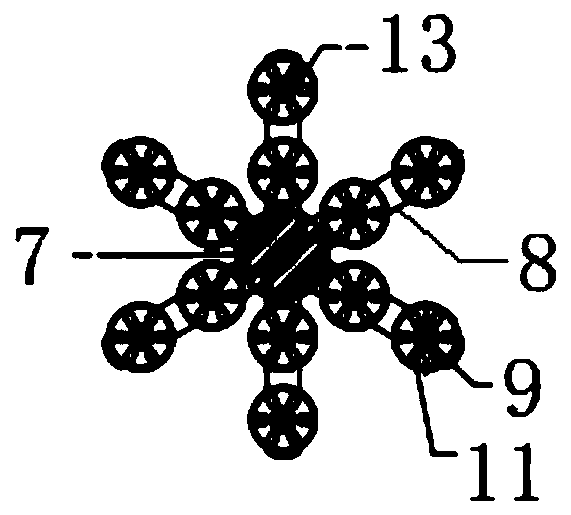

[0058] An embodiment of the present disclosure provides a multi-point ground flare, including:

[0059] Multi-stage combustion system, each stage combustion system includes a plurality of burners 1, the multi-stage combustion system is connected with an exhaust gas source pipeline 2, and the exhaust gas source pipeline 2 can transport combustible gas to the burner 1 for ejection;

[0060] Each stage of the combustion system is provided with an ignition system corresponding to it, and the ignition system can ignite the combustible gas emitted by the burner 1;

[0061] The control unit controls each level of ignition system to ignite its corresponding combustion system.

[0062] Specifically, the exhaust gas discharge pipeline 2 is connected with the combustible exhaust gas discharge port of the chemical plant, and the combustible exhaust gas enters the combustion system through the exhaust gas source pipeline 2 for combustion. On and off, the control unit is the PLC control ca...

Embodiment 2

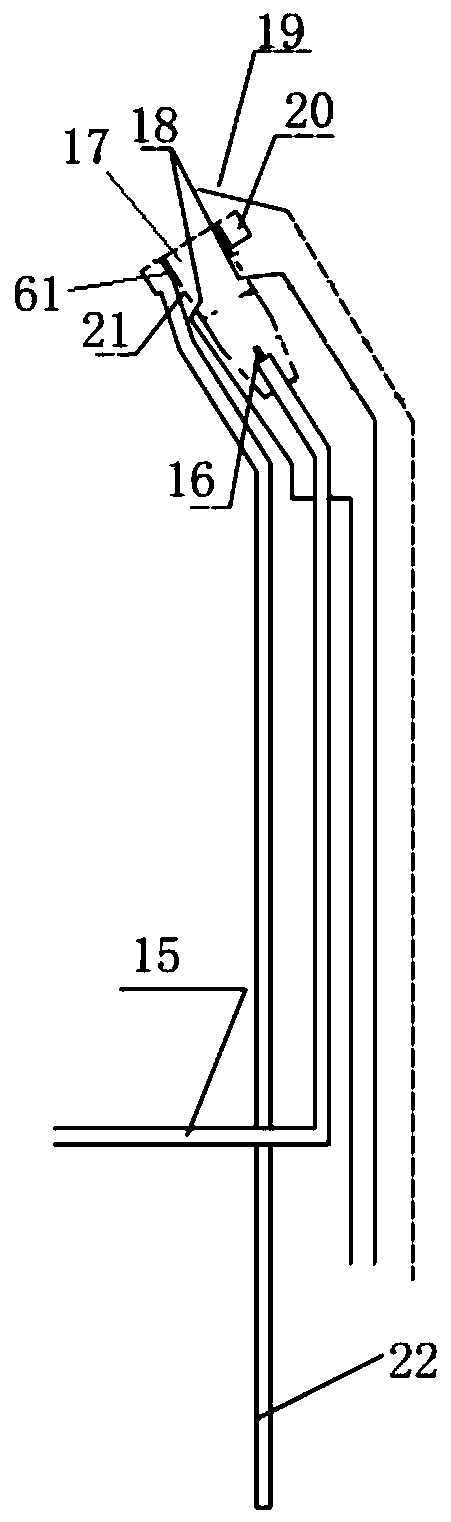

[0105] An embodiment of the present disclosure provides a multi-point ground flare, including:

[0106] Multi-stage combustion system, each stage combustion system includes a plurality of burners 1, the multi-stage combustion system is connected with an exhaust gas source pipeline 2, and the exhaust gas source pipeline 2 can transport combustible gas to the burner 1 for ejection;

[0107] Each stage of the combustion system is provided with an ignition system corresponding to it, and the ignition system can ignite the combustible gas emitted by the burner 1;

[0108] The control unit controls each level of ignition system to ignite its corresponding combustion system.

[0109] Specifically, the gas source pipeline 2 is connected with the combustible waste gas discharge port of the chemical plant, and the combustible waste gas enters the combustion system through the gas source pipeline 2 for combustion, and the control unit can control the opening of the combustion systems at ...

Embodiment 3

[0140] An embodiment of the present disclosure provides a multi-point ground flare, including:

[0141] Multi-stage combustion system, each stage combustion system includes a plurality of burners 1, the multi-stage combustion system is connected with an exhaust gas source pipeline 2, and the exhaust gas source pipeline 2 can transport combustible gas to the burner 1 for ejection;

[0142] Each stage of the combustion system is provided with an ignition system corresponding to it, and the ignition system can ignite the combustible gas emitted by the burner 1;

[0143] The control unit controls each level of ignition system to ignite its corresponding combustion system.

[0144] Specifically, the gas source pipeline 2 is connected with the combustible waste gas discharge port of the chemical plant, and the combustible waste gas enters the combustion system through the gas source pipeline 2 for combustion, and the control unit can control the opening of the combustion systems at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com