a porous sno 2 Microsheet and its preparation method and its application in the positive electrode of lead-carbon battery

A technology of micron flakes and polyvinylpyrrolidone, applied in the direction of lead-acid battery electrodes, battery electrodes, lead-acid batteries, etc., can solve the problems of inappropriate large-scale preparation of lead-carbon batteries, improve discharge capacity and power performance, and simple preparation technology , reduce the effect of concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

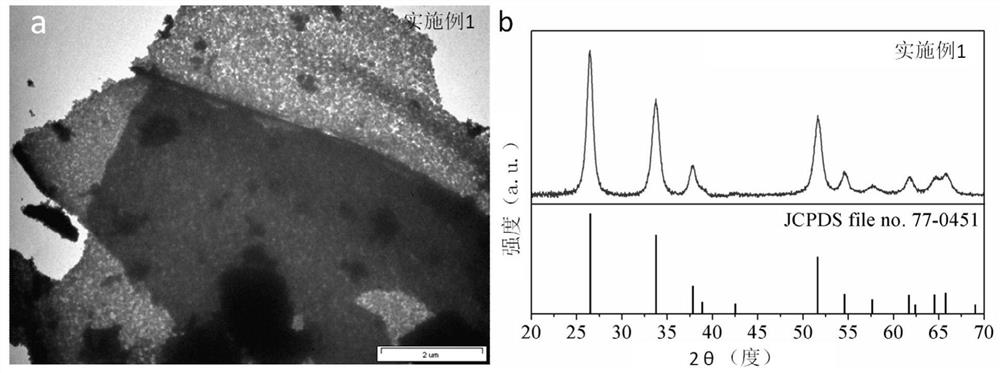

Embodiment 1

[0034] (1) Add polyvinylpyrrolidone to ethanol at a certain mass ratio and stir to dissolve, wherein; polyvinylpyrrolidone: ethanol = 2:100;

[0035] (2) A certain quality of tin tetrachloride pentahydrate is added in the ethanol solution of above-mentioned PVP, obtains white precipitate, wherein the mass ratio of PVP and tin tetrachloride pentahydrate is 1:1;

[0036] (3) filter the above-mentioned white precipitate solution, and reclaim ethanol for reuse;

[0037] (4) Dry the white precipitate in an oven at a temperature of 80° C. for 5 hours;

[0038] (5) Heat the above-mentioned dried powder to 400°C at a heating rate of 1°C / min in a muffle furnace, keep it for 1h for calcination, and cool naturally to obtain porous SnO 2 micron flakes.

Embodiment 2

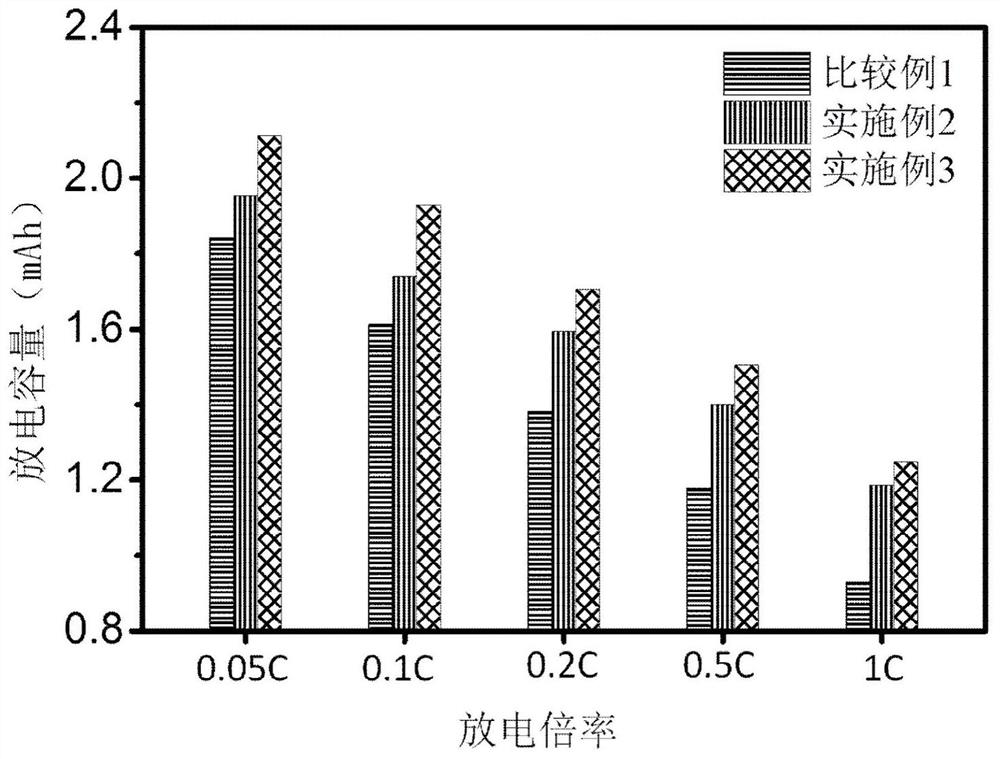

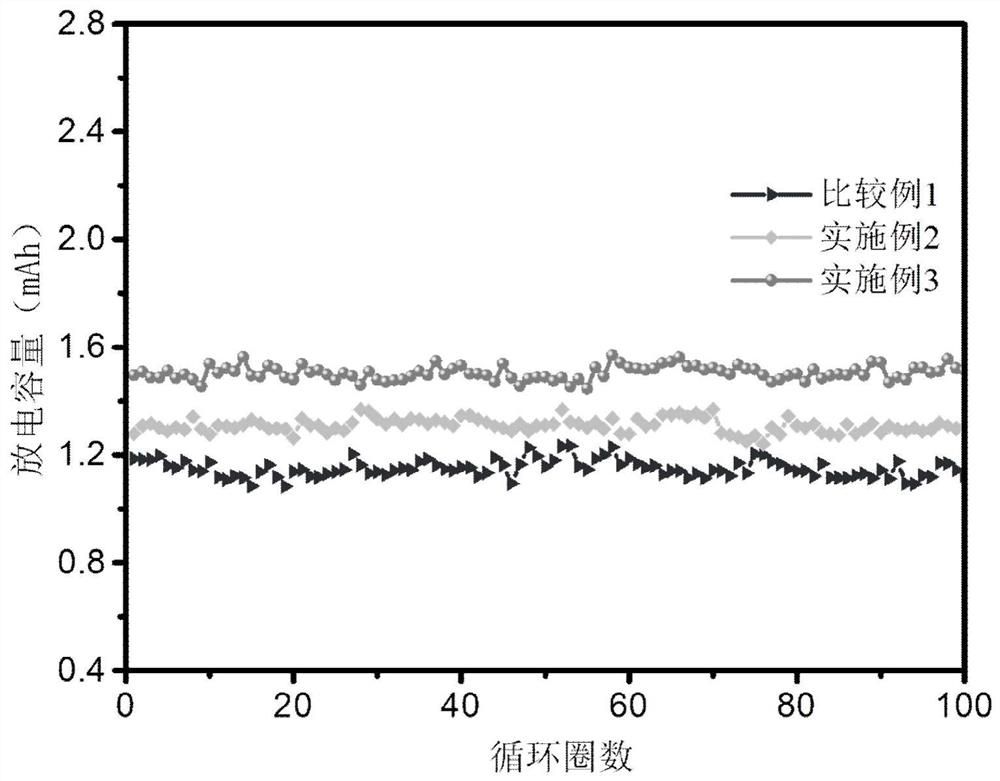

[0040] (1) The porous SnO prepared by commercial positive electrode lead powder and embodiment 1 2 The micron flake additive was mixed in the stirrer for 2 hours according to 100:0.5 (mass ratio), and the required lead-carbon battery positive electrode material was obtained;

[0041] (2) Place the obtained 100g of positive electrode material in a stirrer, add 11.5g of deionized water and grind until uniform, then add 8.8g of it with a density of 1.41g / cm 3 The sulfuric acid is mixed uniformly to obtain a pre-coated lead paste, and the lead paste is evenly coated on the grid to make a green electrode plate (length 7cm and width 4cm), and the coating quality is 22 ± 0.5g. Then wrap the raw plate with non-woven fabric and roll it with polyethylene rod.

[0042] (3) Remove the wrapped non-woven fabric, and then dry the raw electrode plate in a drying oven with a relative humidity ≥ 98% and 65°C for 24 hours, and then dry it in an ordinary drying oven at 60°C for 24 hours. plate....

Embodiment 3

[0046] (1) The porous SnO prepared by commercial positive electrode lead powder and embodiment 1 2 The micron flake additive was mixed in the stirrer for 2 hours according to 100:1 (mass ratio), and the required lead-carbon battery positive electrode material was obtained;

[0047] (2) Place the obtained 100g of positive electrode material in a stirrer, add 11.5g of deionized water and grind until uniform, then add 8.8g of it with a density of 1.41g / cm 3 The sulfuric acid is mixed uniformly to obtain a pre-coated lead paste, and the lead paste is evenly coated on the grid to make a green electrode plate (length 7cm and width 4cm), and the coating quality is 22 ± 0.5g. Then wrap the raw plate with non-woven fabric and roll it with polyethylene rod.

[0048] (3) Remove the wrapped non-woven fabric, and then dry the raw electrode plate in a drying oven with a relative humidity ≥ 98% and 65°C for 24 hours, and then dry it in an ordinary drying oven at 60°C for 24 hours. plate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com