C80 ultrahigh pumping concrete and preparation method thereof

An ultra-high pumping and concrete technology, applied in the field of concrete, can solve the problems of low shear strength and reduce the fluidity of concrete, and achieve the effects of enhancing work performance, improving workability, and increasing the amount of slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

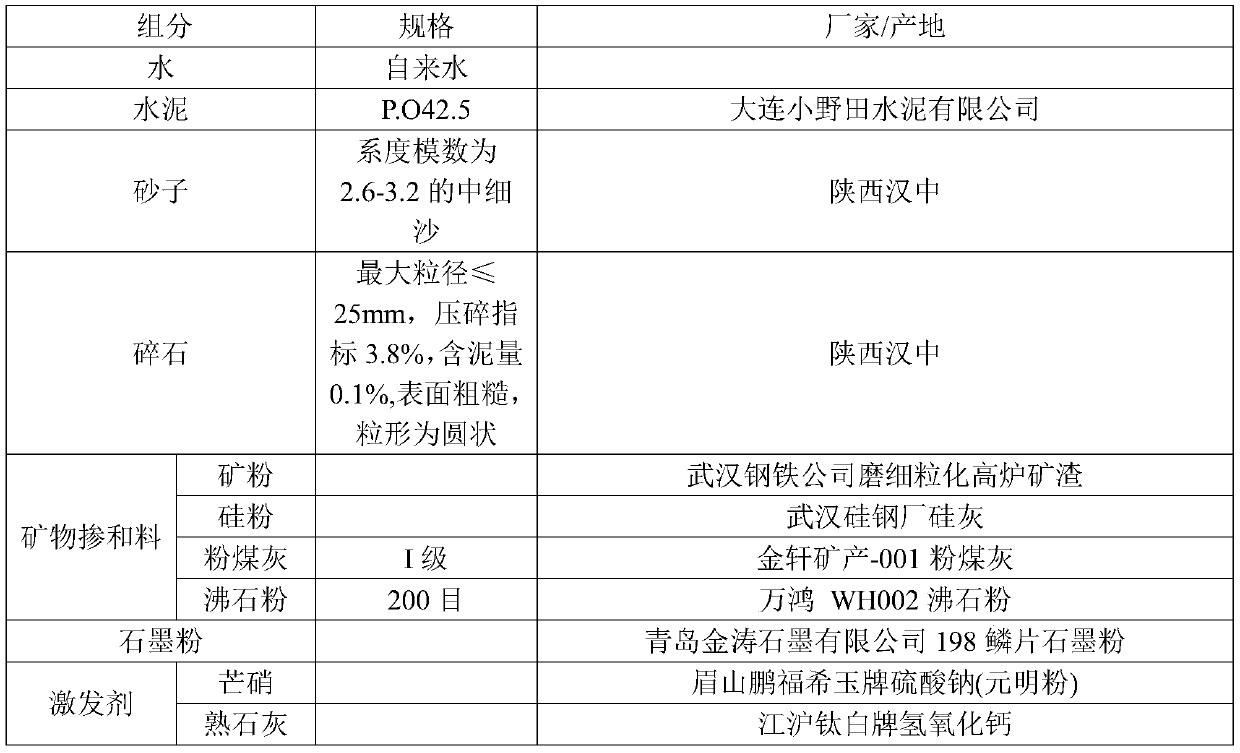

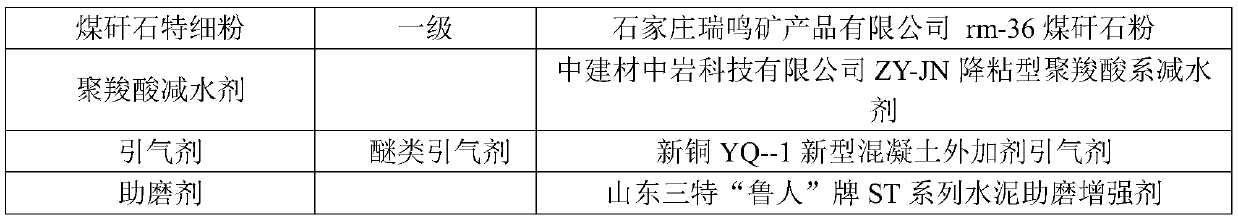

[0057] Example 1: A C80 ultra-high pumping concrete, the components in its raw materials and their corresponding parts by weight are shown in Table 2.

[0058] A preparation method of C80 ultra-high pumping concrete is as follows:

[0059] Step 1, take by weighing the cement of 270-310kg as shown in table 1, the fine sand of 690-720kg, the crushed stone of 50-990kg, the fly ash of 166-206kg, the zeolite powder of 54-74kg, 25- 56kg of graphite powder, 1.1-1.3kg of Glauber's salt, 1.2-1.4kg of slaked lime and 10-30kg of ultra-fine coal gangue powder are stirred and mixed evenly to obtain the first mixture;

[0060] Step 2: Mix 135-147kg of tap water, 8.5-10.5kg of polycarboxylate water reducer and 0.0075-0.145kg of ether air-entraining agent and add them into the first mixture, and stir evenly to obtain C80 ultra-high pumpable concrete.

Embodiment 2-3

[0061] Example 2-3: A C80 ultra-high pumping concrete. The difference from Example 1 lies in the content of the components. The components of the raw materials and their corresponding parts by weight are shown in Table 2.

Embodiment 4

[0062] Embodiment 4: A kind of C80 ultra-high pumping concrete, the difference with embodiment 1 lies in the difference of component content, as shown in table 2, mineral admixture adopts 250kg / m 3 The Wuhan Iron and Steel Company produces fine-grained blast furnace slag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com