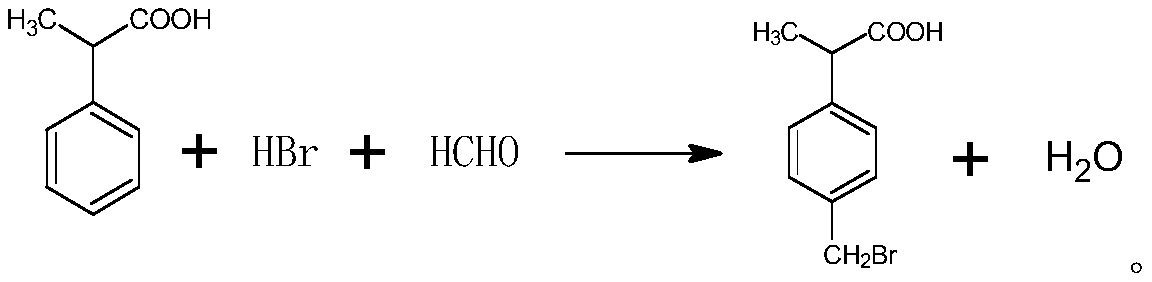

Preparation method of p-bromomethyl isophenylpropionic acid

A technology of p-bromomethylisophenylpropionic acid and phenylpropionic acid, which is applied in the field of synthesis of pharmaceutical intermediates, and can solve the problem of large-scale industrial production of bromomethylisophenylpropionic acid and the difficulty of obtaining 4-methylstyrene , high cost of 4-methylstyrene, etc., to achieve the effect of easy purchase, low price and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

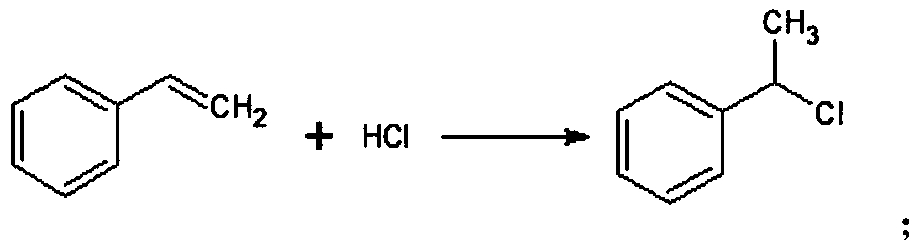

[0045] Synthesis of A, α-methylbenzyl chloride

[0046] Put 300g of dichloromethane and 100g of styrene into the addition kettle, control the temperature at -5 ~ 5°C, and continuously feed dry hydrogen chloride to react for 10 hours; after the reaction, blow off the residual hydrogen chloride with nitrogen; then distill at atmospheric pressure Remove dichloromethane, high vacuum rectification obtains 133g α-methyl benzyl chloride, after testing, the purity of α-methyl benzyl chloride is 98.3%, and the yield is 98.1%;

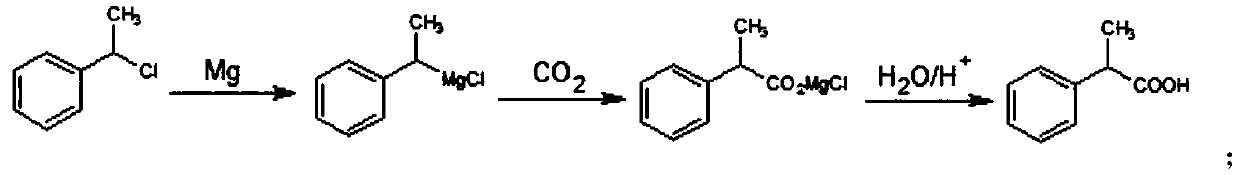

[0047] Synthesis of B, 2-phenylpropionic acid

[0048] Dissolve 133g of α-methylbenzyl chloride in 665g of 2-methyltetrahydrofuran, add magnesium powder with a molar ratio (calculated as α-methylbenzyl chloride) of 2 times, and react at 10-20°C for 3 hours to prepare a Grignard solution; Control 5-15°C, pass through dry carbonic acid gas with a molar ratio of 1.5 times, and react for 5 hours to obtain a carboxylated solution. After the reaction was finished, 2...

Embodiment 2

[0052] Synthesis of A, α-methylbenzyl chloride

[0053] Put 200g of dichloromethane and 100g of styrene into the addition kettle, control the temperature at 0-10°C, and continuously feed dry hydrogen chloride to react for 15 hours; after the reaction, blow off the residual hydrogen chloride with nitrogen; Except dichloromethane, high vacuum rectification obtains 128g α-methyl benzyl chloride, after testing, the purity of α-methyl benzyl chloride is 98.0%, and the yield is 94.4%;

[0054] Synthesis of B, 2-phenylpropionic acid

[0055]Dissolve 128g of α-methylbenzyl chloride in 512g of 2-methyltetrahydrofuran, add magnesium powder with a molar ratio of 1.8 times (in terms of α-methylbenzyl chloride), and react at 0-10°C for 10 hours to prepare a Grignard solution; Controlling -15~-5℃, passing through dry carbonic acid gas with a molar ratio of 1.5 times, and reacting for 5 hours to obtain a carboxylated solution. After the reaction was finished, 2-methyltetrahydrofuran was re...

Embodiment 3

[0059] Synthesis of A, α-methylbenzyl chloride

[0060] Put 400g of dichloromethane and 100g of styrene into the addition kettle, control the temperature at 10-20°C, and continuously feed dry hydrogen chloride to react for 5 hours; after the reaction, blow off the residual hydrogen chloride with nitrogen; Except dichloromethane, high vacuum rectification obtains 130g α-methyl benzyl chloride, after testing, the purity of α-methyl benzyl chloride is 98.1%, and the yield is 95.9%;

[0061] Synthesis of B, 2-phenylpropionic acid

[0062] Dissolve 130g of α-methylbenzyl chloride in 780g of 2-methyltetrahydrofuran, add magnesium powder at a molar ratio of 2.2 times (in terms of α-methylbenzyl chloride), and react at 20-30°C for 5 hours to prepare a Grignard solution; Control 20-30°C, pass through dry carbonic acid gas with a molar ratio of 1.5 times, and react for 5 hours to obtain a carboxylated solution. After the reaction was finished, 2-methyltetrahydrofuran was removed by at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com