Soil conditioner and soil improvement method thereof

A soil conditioner and diatomite technology, which can be used in soil preparation methods, soil conditioning materials, chemical instruments and methods, etc., can solve the problems of poor organic and heavy metal treatment results and high production costs, and achieve rich surface functional groups and strong adsorption. Ability, the effect of enriching the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

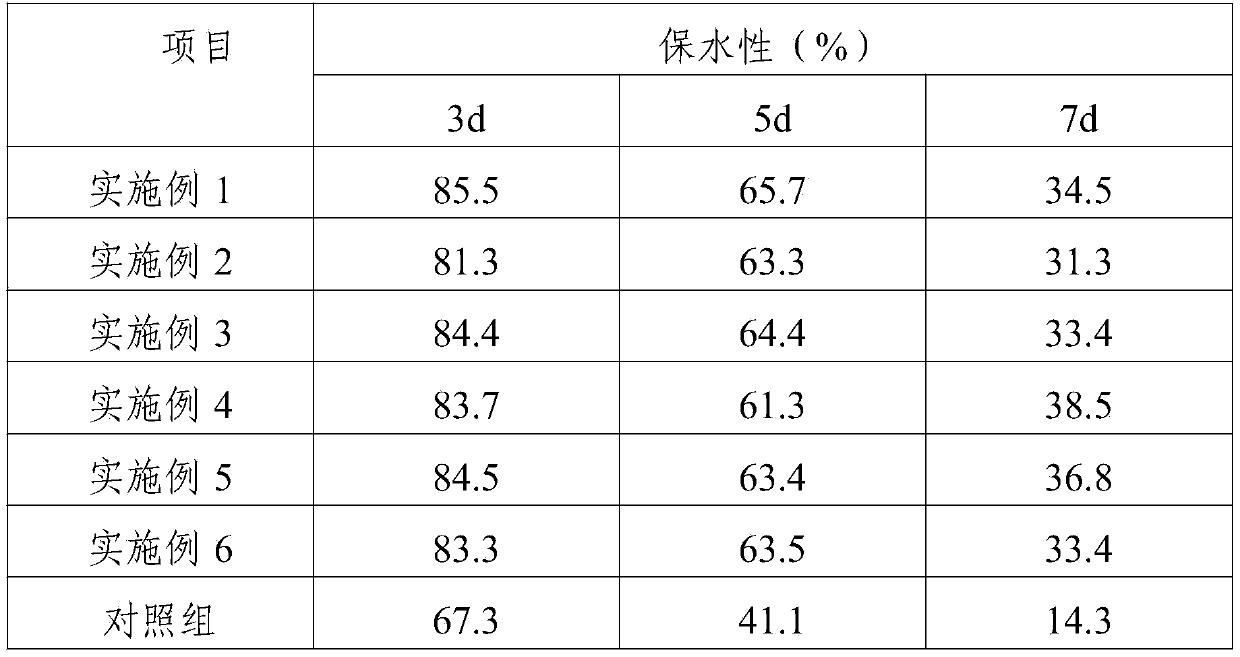

Examples

Embodiment 1

[0025] A soil conditioner, comprising the following raw materials in parts by weight: 26 parts of diatomaceous earth, 6 parts of polyacrylamide, 5 parts of polyvinyl alcohol, 65 parts of humic acid matrix, 4 parts of composite microbial agent, and hydroxypropyl methyl fiber 8 parts of sodium lauryl sulfate and 5 parts of sodium lauryl sulfate.

[0026] The method for preparing the soil amendment includes the following steps:

[0027] (1) The humic acid matrix is crushed and pretreated with a 4wt% nitric acid solution. The volume of the nitric acid solution added is 25% of the humic acid matrix. The pretreatment method is to stir and mix and place it at room temperature for 2 days, then mix with the compound bacteria Mix to obtain component A;

[0028] (2) Mix diatomaceous earth, polyacrylamide, and polyvinyl alcohol uniformly to obtain a dry powder. Add 70% of the total mass of the dry powder to the dry powder and stir and mix to obtain a wet powder. After the wet powder is granul...

Embodiment 2

[0031] A soil conditioner, comprising the following raw materials in parts by weight: 25 parts of diatomaceous earth, 6 parts of polyacrylamide, 5 parts of polyvinyl alcohol, 60 parts of humic acid matrix, 3 parts of composite microbial agent, and hydroxypropyl methyl fiber 5 parts of sodium lauryl sulfate and 8 parts of sodium lauryl sulfate.

[0032] The method for preparing the soil amendment includes the following steps:

[0033] (1) After crushing the humic acid matrix, pretreat it with a 5wt% nitric acid solution. The volume of the nitric acid solution added is 30% of the humic acid matrix. The pretreatment method is to stir and mix at room temperature for 2 days, and then mix with the compound bacteria Mix to obtain component A;

[0034] (2) Mix diatomaceous earth, polyacrylamide, and polyvinyl alcohol uniformly to obtain a dry powder. Add 80% of the total mass of the dry powder to the dry powder and stir and mix to obtain a wet powder. After granulating the wet powder, Dryi...

Embodiment 3

[0037] A soil conditioner comprising the following raw materials in parts by weight: 30 parts of diatomaceous earth, 5 parts of polyacrylamide, 4 parts of polyvinyl alcohol, 70 parts of humic acid matrix, 5 parts of composite microbial agent, and hydroxypropyl methyl fiber 8 parts of sodium lauryl sulfate and 6 parts of sodium lauryl sulfate.

[0038] The method for preparing the soil amendment includes the following steps:

[0039] (1) The humic acid matrix is crushed and pretreated with a 2wt% nitric acid solution. The volume of the nitric acid solution added is 25% of the humic acid matrix. The pretreatment method is to stir and mix and place at room temperature for 1d, and then mix with the compound bacteria Mix to obtain component A;

[0040] (2) Mix diatomaceous earth, polyacrylamide and polyvinyl alcohol uniformly to obtain a dry powder. Add 60% of the total mass of the dry powder to the dry powder and stir and mix to obtain a wet powder. After granulating the wet powder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com