Steel box arch bridge single arch rib framing swivel system and construction method thereof

A single-arch rib and arch bridge technology, which is applied to the single-arch rib swivel system of steel box arch bridges and its construction field, can solve the problems of difficult protection, large amount of excavation in the construction mountain, easy to induce geological disasters, etc. The turntable is too large, the effect of solving the large amount of arch excavation and reducing the amount of protection works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

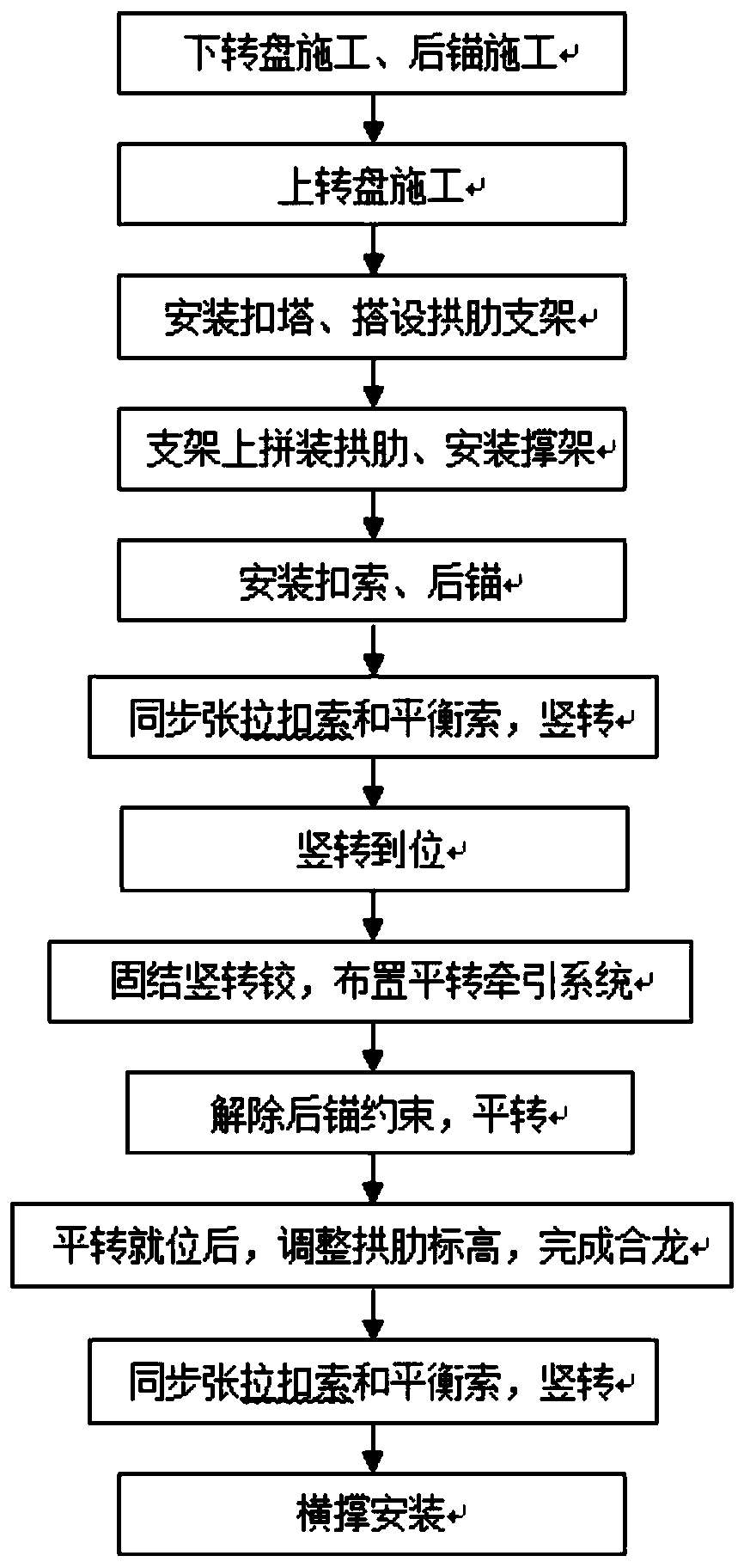

[0051] Such as figure 1 The construction method of a single arch rib framing swivel system of a steel box arch bridge is shown, including the following steps:

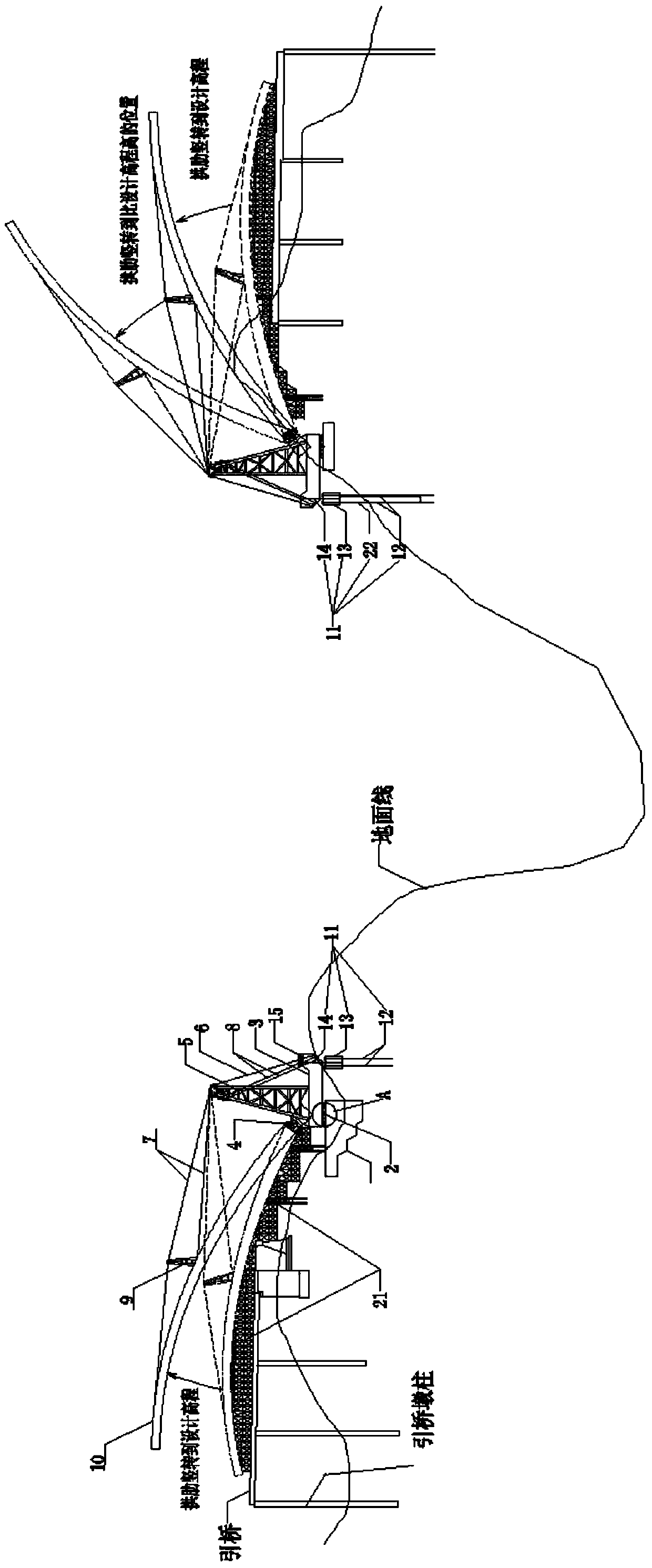

[0052] A. Construction of the lower turntable: pouring concrete to form the lower turntable 1, and reserve a notch for the loop, a notch for the ball hinge 16 and a notch for the rear anchor on the lower turntable 1, and install a steel plate for the loop on the notch of the loop as an annular slideway. Install the spherical hinge 16 on the notch of the spherical hinge 16, accurately adjust the elevation of the ring steel plate and the position of the spherical hinge 16, pour concrete in each notch, and pour the traction reaction seat 19 and the jack reaction seat 20;

[0053] B. Rear anchor construction: the rear anchor adopts prestressed rock anchor 12. Before the prestressed rock anchor 12 is constructed, the anchorage force failure test of the rock anchor is required, that is, the pull-out test. After the anchorage...

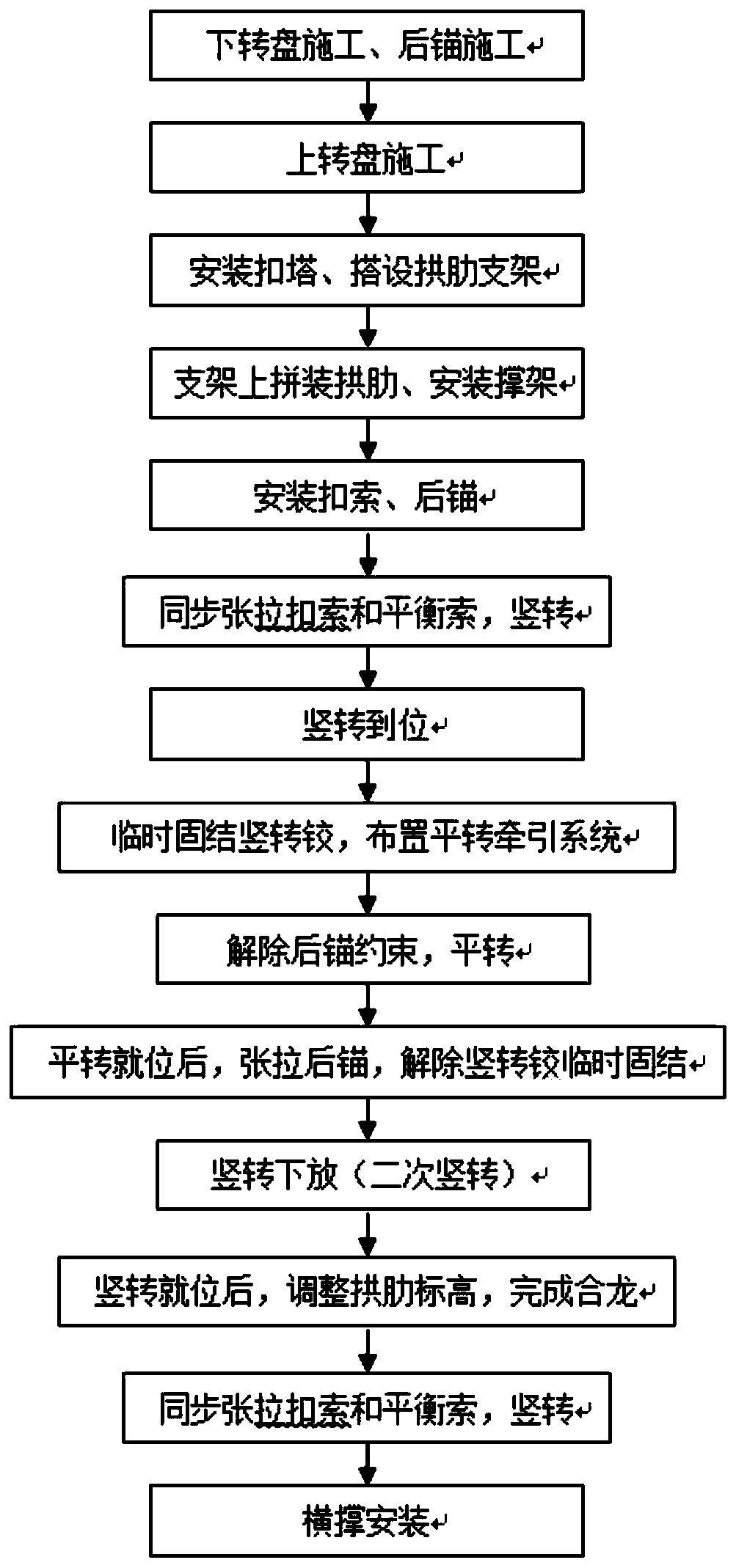

Embodiment 2

[0061] The difference between embodiment 2 and embodiment 1 is that for the arch rib 10 that has been rotated vertically for the second time, in step E, the arch ribs 10 on both sides are rotated horizontally and then ready to be closed, the upper turntable 3 and the lower turntable 1 are consolidated, and the concrete seal is poured. Fix the upper turntable 3 and the lower turntable 1, and simultaneously tension the rear anchor, and prepare to lower the entire swivel body.

[0062] Step F: After the arch ribs 10 on both sides are rotated in place, they start to lower to the design elevation. After the arch axis meets the requirements, the mid-span closure section is welded. After the arch ribs 10 are closed, the buckle cables and balance cables 8 are gradually loosened, and the arch feet are vertically hinged. 4 Sealing, becoming a fixed end, and completing the 10-rotation construction of the arch rib.

[0063] The single arch rib 10 adopts a lying posture and is located behi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com