A kind of method and application thereof to lithium metal polishing

A technology of lithium metal and lithium metal electrodes, which is applied in the coating process of metal materials, lithium batteries, structural parts, etc., can solve the continuous side reactions between lithium dendrites and organic electrolytes, uncontrollable growth of lithium dendrites, low cycle life, etc. problems, to achieve excellent electrochemical performance, excellent electrochemical performance, reliable and practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

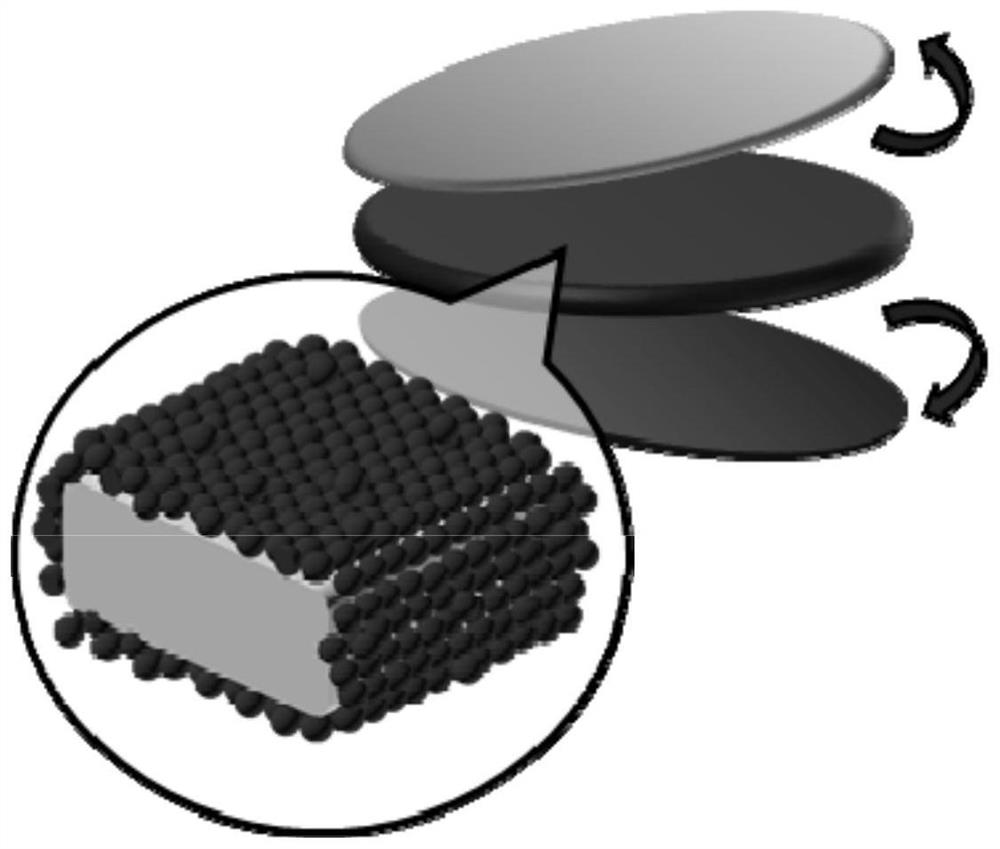

[0059] Under the high-purity argon atmosphere in the glove box, the lithium foil was soaked in SnCl 4 -DME mixed solution (in this mixed solution, SnCl 4 The volume ratio of DME and DME is 1:99), take it out after soaking for 5 minutes, evaporate naturally, then put lithium metal into an airtight container and use an oscillator for low-frequency oscillation, the frequency is 200Hz, the original layer on the surface of lithium metal can be peeled off, The lithium metal wrapped by the Sn-LiCl mixed protective layer was obtained. The schematic diagram of the polishing reaction is shown in figure 1 As shown, Sn exists in the structure of nanospheres, and the main component of the edge and periphery, as well as the places where the particles are in contact, is LiCl.

[0060] Using a commercial ternary cathode (NCM811), the electrolyte uses 1mol / L LiTFSI, and the loading capacity of the cathode material is about 26mg cm -2 , matching the prepared lithium metal, cycled at a charge...

example 2

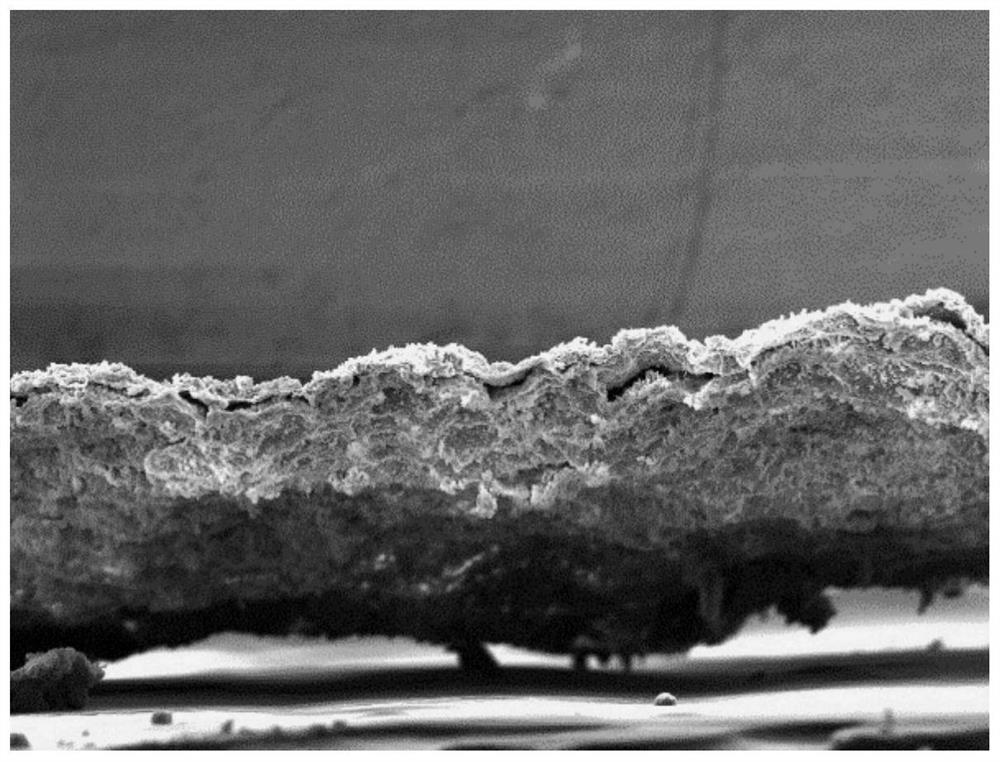

[0062] Under an inert atmosphere in a glove box, soak Li metal in SnF 2 -THF mixed solution (in this mixed solution, SnF 2 The volume ratio of THF and THF is 1:99), soaked for 5 minutes, took it out, evaporated to dryness naturally, and then put lithium metal into an airtight container for low-frequency vibration at a frequency of 130 Hz, the original layer on the surface of lithium metal was peeled off, and Sn - Lithium metal wrapped in a LiF hybrid protective layer. The SEM image of the original oxide layer on the lithium metal surface obtained figure 2 shown.

[0063] Using the same method and test conditions as in Example 1, record the number of cycles to keep more than 80% of the capacity (see Table 1).

example 3

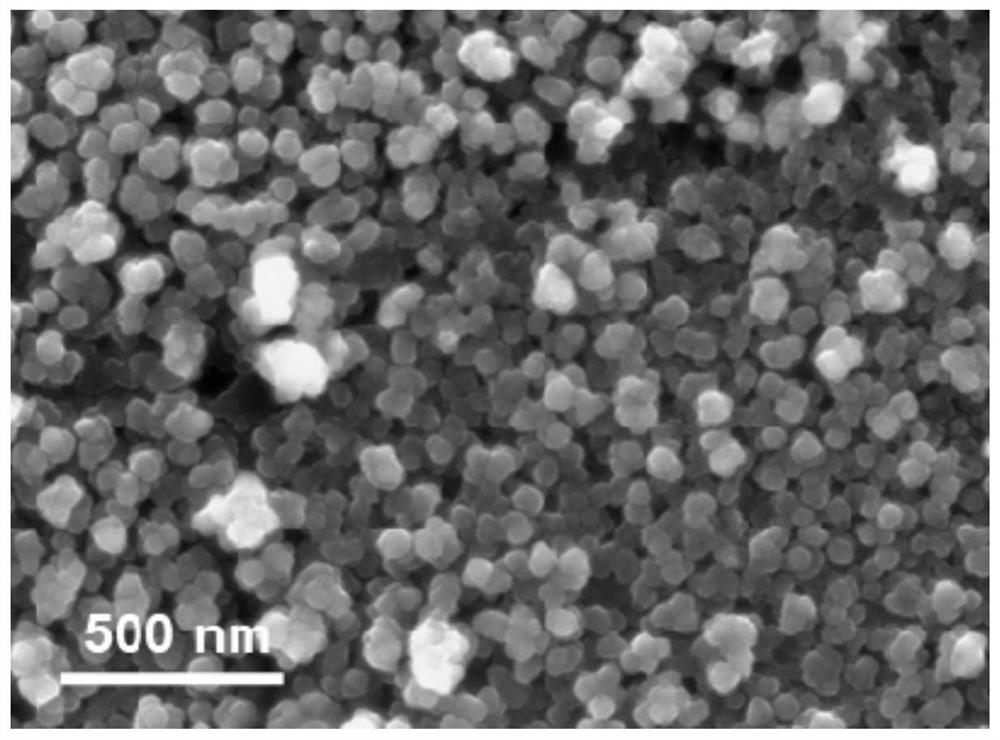

[0065] Under an inert atmosphere in a glove box, immerse lithium metal in TiCl 4 -THF mixed solution (in this mixed solution, TiCl 4 The volume ratio of THF and THF is 1:99), take it out after soaking for 5 minutes, heat and bake the lithium metal (50°C), and then put the lithium metal into an airtight container for low-frequency oscillation, the frequency is 85Hz, the original surface of the lithium metal The layer is peeled off, and the lithium metal wrapped by the Ti-LiCl mixed protective layer is obtained. The SEM image of the newly formed Ti-LiCl protective layer on the surface of lithium metal is shown in image 3 .

[0066]Using the same method and test conditions as in Example 1, record the number of cycles to keep more than 80% of the capacity (see Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com