Interlayer material and preparation method and application thereof

An interlayer material and reaction technology, which is used in electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of insufficient polysulfide contact, slow lithium ion migration, and insufficient conductivity of carbon materials. Liquid storage and ion migration, shortening the lithium ion transmission path, and facilitating the effect of industrial large-scale production applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This embodiment provides a method for preparing a sandwich material, including the following steps:

[0069] (1) Dissolve 3.2 mol of cobalt nitrate hexahydrate, 1 mol of ammonium molybdate tetrahydrate and 6 mol of thiourea in 80 mL of deionized water, and stir at room temperature until the solution is clear to obtain a pink solution;

[0070] (2) Dissolve 32 mol of 2-methylimidazole in 80mL of deionized water, stir at room temperature until the solution is clear, and obtain an aqueous solution of 2-methylimidazole;

[0071] (3) Pour the 2-methylimidazole aqueous solution obtained in step (2) into the pink solution obtained in step (1) to obtain a dark purple solution, and let it stand for 24 hours to obtain a preform;

[0072] (4) Suction filtration of the preform obtained in step (3) to remove the supernatant. After dispersing the obtained precipitate in the ethanol / water mixed solution, suction filtration and repeated washing four times until the precipitate completely turns ...

Embodiment 2

[0078] The only difference from Example 1 is that step (1) does not include adding thiourea, and the rest of the composition and preparation method are the same as those of Example 1.

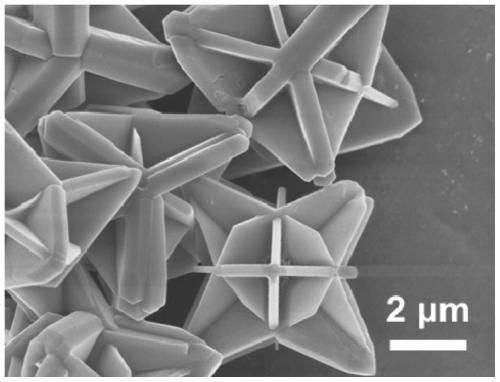

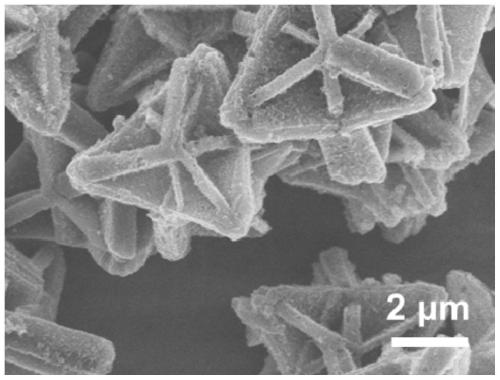

[0079] image 3 In order to obtain the scanning electron microscope image of the starfruit-shaped precursor, from image 3 It can be seen that the particle size of the obtained product is about 4μm, the particle morphology is similar to star fruit, the particles are connected, and the surface is smooth;

[0080] Figure 4 To obtain the scanning electron microscope image of the sandwich material, from Figure 4 It can be seen that the particle size of the obtained product is about 4 μm, the particle morphology is similar to star fruit, the particles are connected, and the surface is rough.

Embodiment 3

[0082] This embodiment provides a method for preparing a sandwich material, including the following steps:

[0083] (1) Dissolve 4mmol of cobalt nitrate hexahydrate, 0.5mmol of ammonium tetrathiomolybdate and 10mmol of thiourea in 80mL of deionized water, and stir at room temperature until the solution is clear to obtain a pink solution;

[0084] (2) Dissolve 10mmol of 1-ethylimidazole in 80mL of deionized water, stir at room temperature until the solution is clear, and obtain an aqueous solution of 1-ethylimidazole;

[0085] (3) Pour the 1-ethylimidazole aqueous solution obtained in step (2) into the pink solution obtained in step (1) to obtain a dark purple solution, and let it stand for 36 hours to obtain a preform;

[0086] (4) Suction filtration of the preform obtained in step (3) to remove the supernatant. After dispersing the obtained precipitate in the ethanol / water mixed solution, suction filtration and repeated washing four times until the precipitate completely turns blue-pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Average porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com