Precision pulse arc spot welding ceramic particle planting method

A ceramic particle and pulsed arc technology, which is applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of large influence on the structure and performance of the base metal, insufficient bonding force, and low efficiency, and achieve low equipment cost investment and automation , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

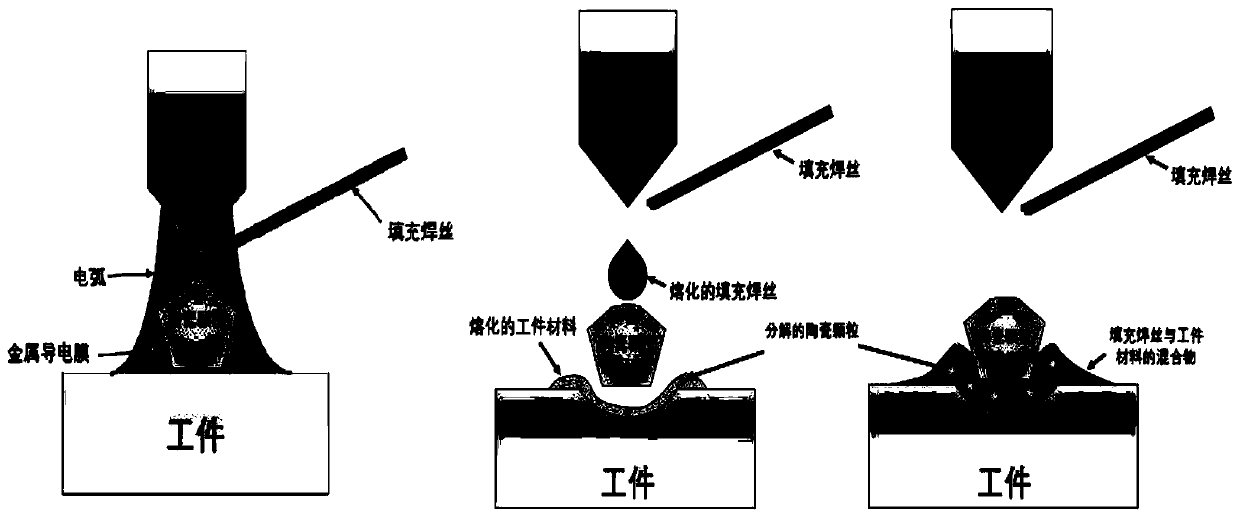

Method used

Image

Examples

Embodiment 1

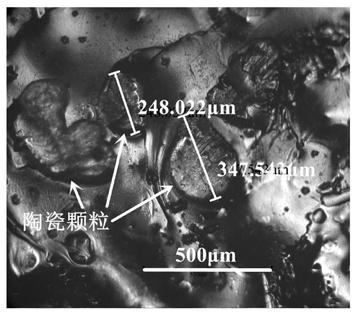

[0028] The nickel-based single crystal superalloy PWA1484 is selected as the workpiece material, and the surface of the workpiece is polished and flattened with anhydrous ethanol to clean and dry. Ceramic particles are selected from Al 2 O 3 Particles, particle size 180μm ~ 380μm, using chemical plating process in Al 2 O 3 A Ni-P alloy conductive layer was prepared on the particle surface with a thickness of 50 μm.

[0029] Connect the workpiece to the negative pole of the precision pulse spot welding machine and adjust the level, the tungsten electrode is connected to the positive pole, the Al with conductive layer 2 O 3 The ceramic particles are evenly spread on the surface of the workpiece.

[0030] The welding wire is made of Ni-based superalloy, and the diameter of the welding wire is 1.6mm. Adjust the spot welding parameters: pulse current 80A, pulse time 40ms, pulse frequency 1Hz, distance between electrode and workpiece 2mm. Place the wire in Al 2 O 3 The top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com