High-performance tantalum disulfide two-dimensional layered film as well as preparation method and application thereof

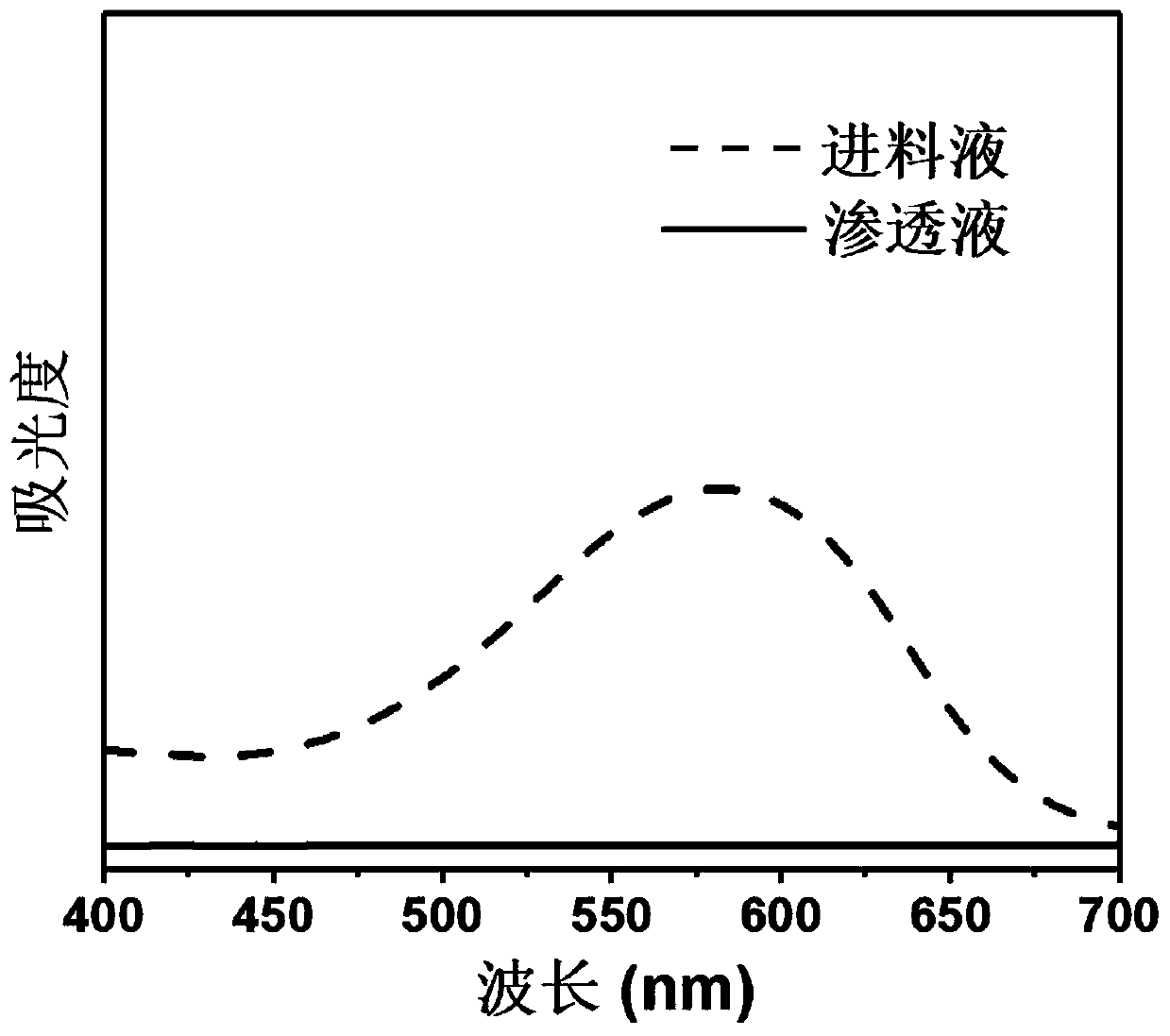

A two-dimensional layered, tantalum disulfide technology, applied in the field of separation membranes, can solve problems such as environmental pollution, complex processes, and a large number of organic waste liquids, and achieve the effects of strong controllability, good repeatability, and high water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A high-performance TaS 2 A method for preparing a two-dimensional layered film, comprising the following steps:

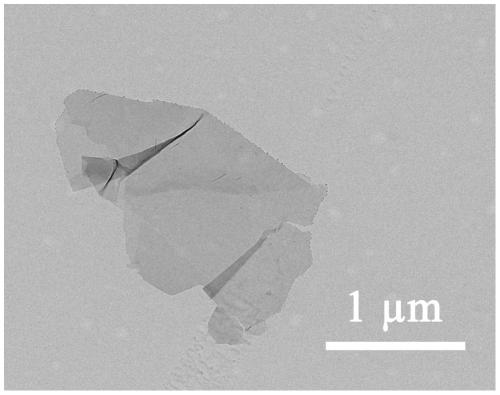

[0028] Step 1. Take tantalum powder and sulfur powder and mix them well at a molar ratio of 1:2, add a small amount of iodine (the amount added is 3.5mg / cm2 based on the volume of the quartz tube) 3 ), in low vacuum (-3 Torr) was sealed in a quartz tube and placed in a muffle furnace. Slowly raise the temperature to 900°C at a heating rate of 50°C / h, keep it for 24 hours, and then quench to obtain high-purity 1T phase TaS 2 crystals, with CCl 4 and CS 2 Repeated washing 3 times in sequence to remove unreacted impurities.

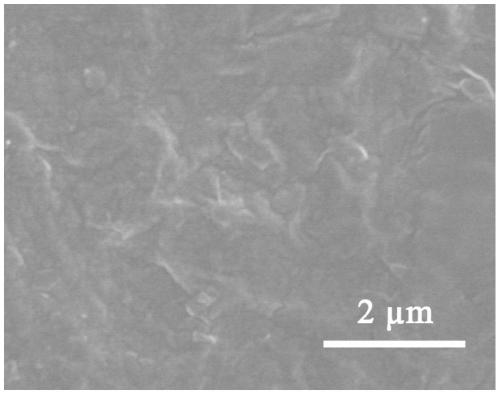

[0029] Step 2, in the glove box, take 30mg of TaS prepared in step 1 2 Add the crystals into a stainless steel reaction kettle, then add 1 mL of n-butyllithium n-hexane solution with a concentration of 1.6 mol / L, and seal it. Lithium intercalation reaction was carried out at 100°C for 2 hours, and the product was washed with n-hexane...

Embodiment 2

[0036] A high-performance TaS 2 A method for preparing a two-dimensional layered film, comprising the following steps:

[0037] Step 1. Take tantalum powder and sulfur powder and mix them evenly at a molar ratio of 1:2, add a small amount of iodine (the amount added is 4mg / cm2 based on the volume of the quartz tube) 3 ), in low vacuum (-3 Torr) was sealed in a quartz tube and placed in a muffle furnace. Slowly raise the temperature to 900°C at a heating rate of 30°C / h, keep it for 72 hours, and then quench to obtain high-purity 1T phase TaS 2 crystals, with CCl 4 and CS 2 Repeated washing 3 times in sequence to remove unreacted impurities.

[0038] Step 2, in the glove box, take 50mg of TaS prepared in step 1 2 Add the crystals into a stainless steel reaction kettle, then add 1 mL of n-butyllithium n-hexane solution with a concentration of 1.6 mol / L, and seal it. Lithium intercalation reaction was carried out at 60°C for 12 hours, and the product was repeatedly washed wi...

Embodiment 3

[0043] A high-performance TaS 2 A method for preparing a two-dimensional layered film, comprising the following steps:

[0044] Step 1. Take tantalum powder and sulfur powder and mix them well at a molar ratio of 1:2, add a small amount of iodine (the amount added is 2 mg / cm2 based on the volume of the quartz tube) 3 ), in low vacuum (-3 Torr) was sealed in a quartz tube and placed in a muffle furnace. Slowly raise the temperature to 900°C at a heating rate of 45°C / h, keep it for 48 hours, and then quench to obtain high-purity 1T phase TaS 2 crystals, with CCl 4 and CS 2 Washing was repeated 5 times successively to remove unreacted impurities.

[0045] Step 2, in the glove box, take 40mg of TaS prepared in step 1 2 Add the crystals into a stainless steel reaction kettle, then add 1 mL of n-butyllithium n-hexane solution with a concentration of 1.6 mol / L, and seal it. Lithium intercalation reaction was carried out at 150°C for 1 h, and the product was washed 5 times with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com