Composite energetic material with embedded structure and preparation method thereof

A technology of dinitrofurazan base and furazan oxide is applied in the directions of explosive compound components, attack equipment, explosive processing equipment, etc., which can solve the problem of inhibiting the reaction completeness and energy level of aluminum-containing explosives, and reducing the release energy level of aluminum-containing explosives. , reduce the oxygen concentration of aluminum powder and other problems, to achieve the effect of promoting the completeness of the reaction, compacting the particles, and reducing the generation of hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

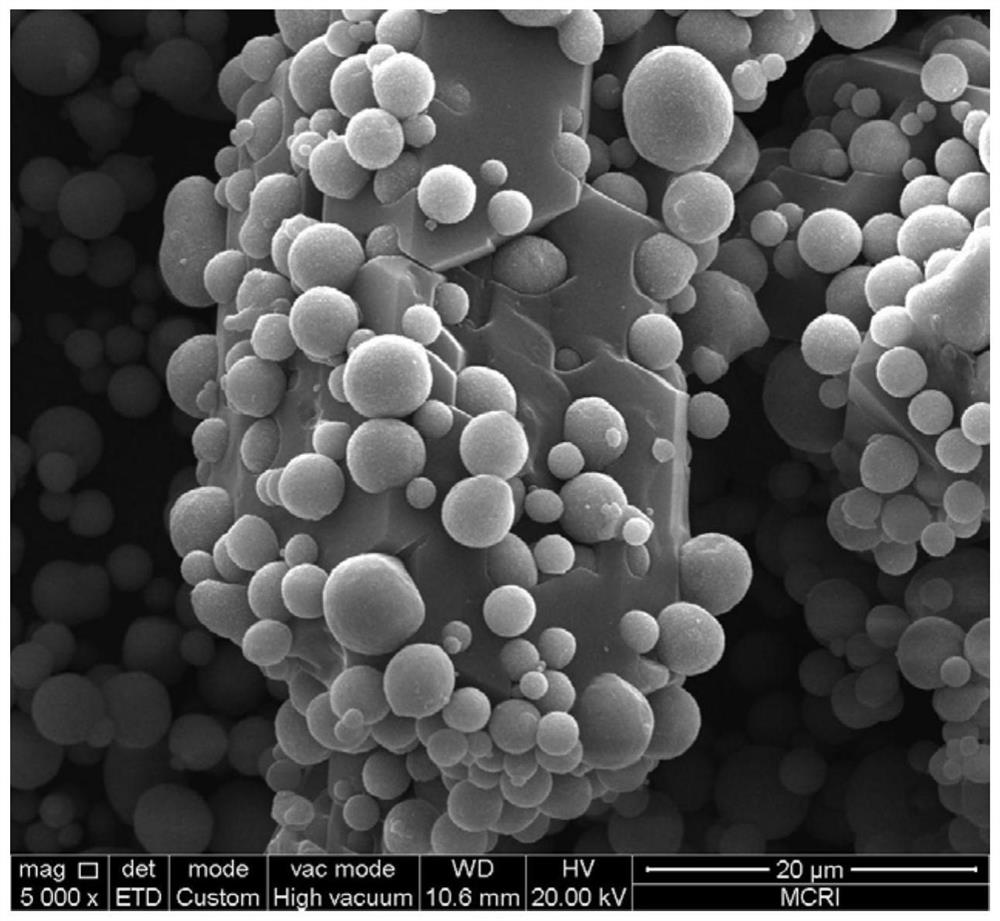

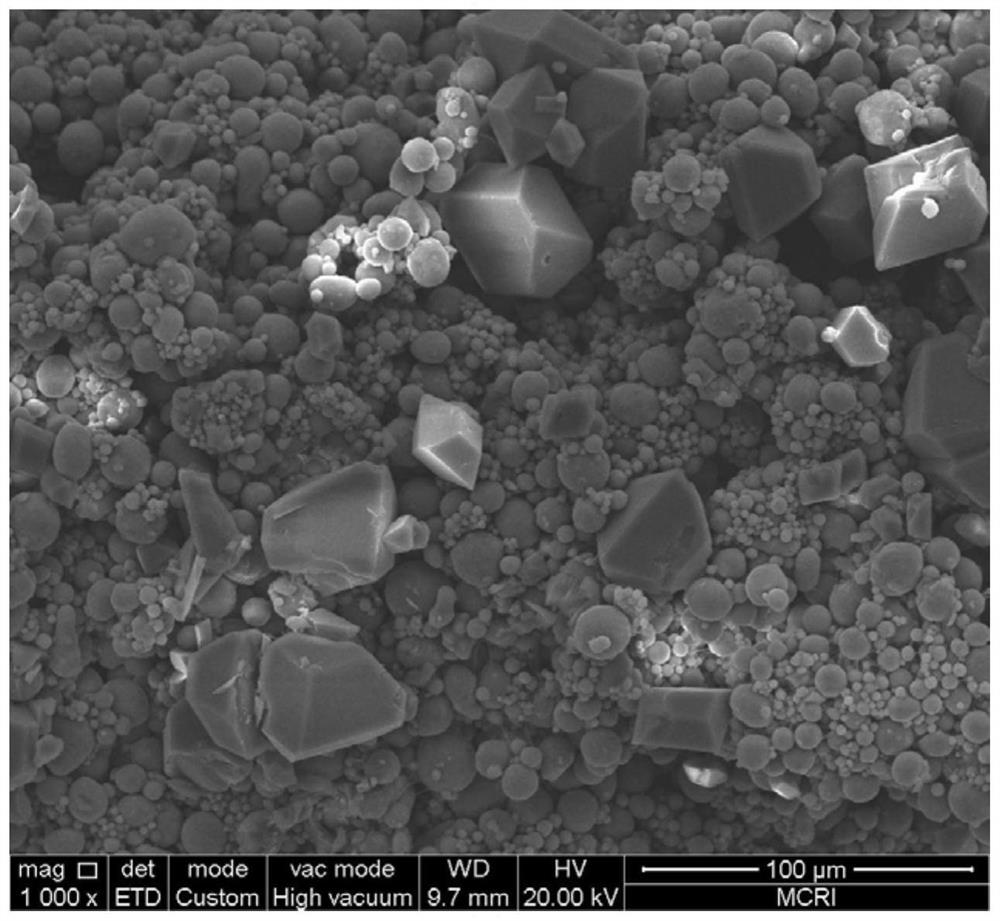

[0026] This embodiment is carried out according to the following mass percentage composition: 68.4% of 3,4-dinitrofurazanyl oxide furazan, and 31.6% of aluminum powder.

[0027] The preparation method of the present embodiment is as follows:

[0028] (1) Weigh 130g of 3,4-dinitrofurazanylfuroxan and add it to a beaker, add it to 300mL ethyl acetate, heat the water bath to 60°C, stir and dissolve to form 3,4-dinitrofurazan The ethyl acetate solution of furoxan, standby;

[0029] (2) Weigh 60g of spherical aluminum powder and add it to the reaction kettle, add it into a n-hexane solvent with a volume of 900mL, and mechanically stir at a rate of 500r / m to form a suspension of aluminum powder;

[0030] (3) Increase the stirring speed to 800r / m, drop the ethyl acetate solution of 3,4-dinitrofurazanyl oxide furazan into the aluminum powder suspension at a speed of 2mL / min, and control the water bath temperature to be 20 ℃, the solution is supersaturated and 3,4-dinitrofurazanyl ox...

Embodiment 2

[0036] This embodiment is carried out with reference to the following composition by weight: 60% of 3,4-dinitrofurazanyl oxide furazan, and 40% of aluminum powder. The preparation steps refer to Example 1.

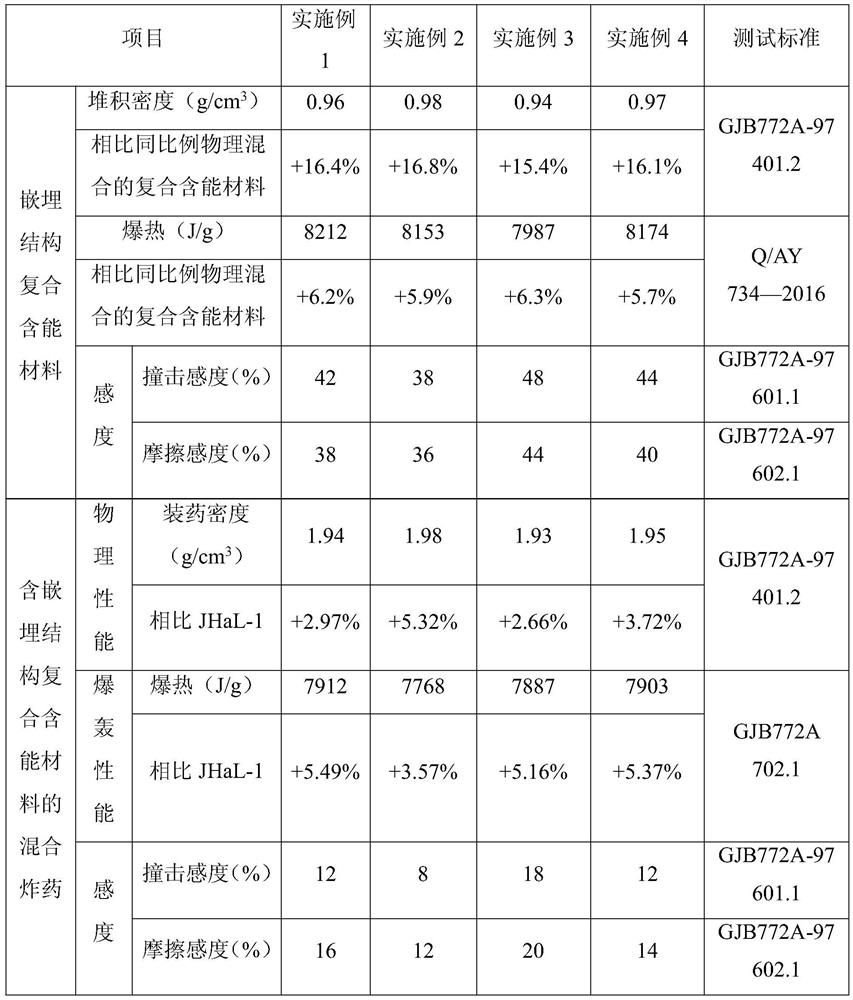

[0037]The performance test data shows that the 3,4-dinitrofurazanylfuroxan / aluminum powder composite energetic material in this example is more effective than the physically mixed 3,4-dinitrofurazanylfuroxan / The bulk density of aluminum powder composite energetic material is increased by 16.8%, the detonation heat is increased by 5.9%, and the sensitivity is low; the molding density of the mixed explosive containing embedded structure composite energetic material is increased by 5.32% compared with JHaL-1, and the detonation heat is compared with JHaL-1 1 lift of 3.57%.

Embodiment 3

[0039] This embodiment is carried out with reference to the following composition by weight: 80% of 3,4-dinitrofurazanyl oxide furazan, and 20% of aluminum powder. The preparation steps refer to Example 1.

[0040] The performance test data shows that the 3,4-dinitrofurazanylfuroxan / aluminum powder composite energetic material in this example is more effective than the physically mixed 3,4-dinitrofurazanylfuroxan / The bulk density of aluminum powder composite energetic material is increased by 15.4%, the heat of detonation is increased by 6.3%, and the sensitivity is low; the molding density of the mixed explosive containing embedded structure composite energetic material is increased by 2.66% compared with JHaL-1, and the heat of detonation is compared with JHaL-1 1 lift of 5.16%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com