Amphoteric gemini surfactant, temperature-resistant and salt-resistant nanoemulsion, preparation method and application thereof

A technology of main surfactant and gemini surface, applied in the direction of chemical instruments and methods, organic chemistry, drilling compositions, etc., can solve the problems of not playing the role, achieve excellent oil-water interfacial tension ability, good viscosity drop Coagulation effect, beneficial to the recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] In some preferred embodiments, the preparation method of the temperature-resistant and salt-resistant nanoemulsion for fracturing fluid comprises the following steps:

[0062] Dissolve the main surfactant and the sub-surfactant in the oil phase, and stir evenly at a stirring speed of 100-400 rpm;

[0063] The temperature is raised to 40-70° C., and after stirring and reacting for 30-50 minutes, water and co-surfactant are slowly added dropwise, and stirring is continued for 30-90 minutes to obtain the temperature-resistant and salt-resistant nanoemulsion for fracturing fluid.

[0064] The method of the present application can prepare a nanoemulsion with low nanometer size and high stability through the combination of various surfactants and a simple synthesis process, and the prepared nanoemulsion has a stability of more than 12 months.

[0065] The nanoemulsion of the present application is small in particle size, and has a small size effect, making it easy to inject i...

Embodiment 1

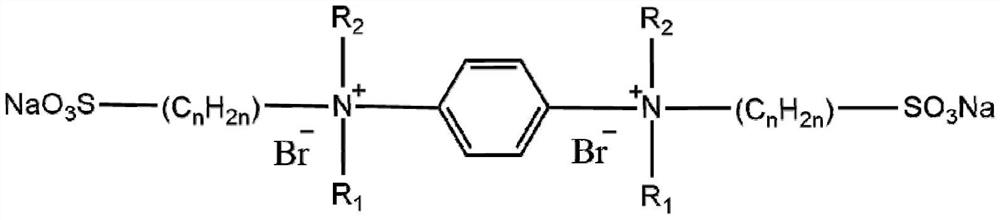

[0069] Preparation of Amphoteric Gemini Surfactant

[0070] In the reactor, start stirring, dissolve 35.8 g of N,N-diethyl-p-phenylenediamine in 200 mL of dichloromethane, add 121.2 g of bromotetradecane, heat up to 60°C, react for 5 hours, then add 82.0 g of sodium 2-bromoethylsulfonate was added, the temperature was raised to 70°C, and the solvent was distilled off after 6 hours of reaction to obtain the amphoteric gemini surfactant.

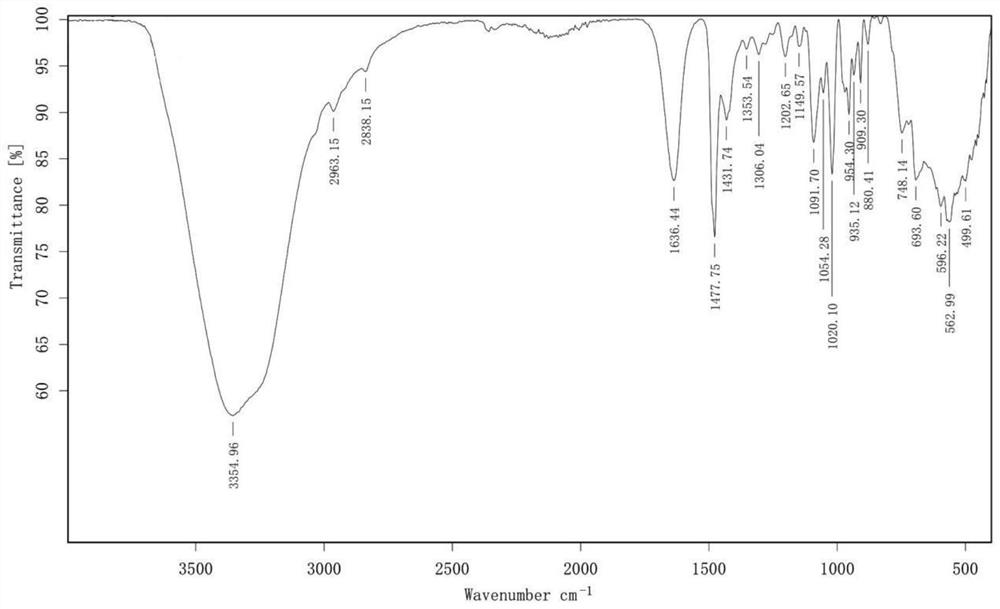

[0071] Wherein, the infrared identification spectrum of the gemini surfactant prepared in this example is as follows: figure 1 shown, from figure 1 It can be seen that the FTIR spectrum of the gemini surfactant is at 2963.15 cm -1 and 2838.15cm -1 There is a stretching vibration absorption peak of methylmethylene C-H on the alkyl chain, at 693.60cm -1 There are skeleton vibration peaks of long-chain methylene groups with carbon number greater than 4, at 1020.10cm -1 Presence of sulfonic acid -SO 3 The stretching vibration absorption peak...

Embodiment 2

[0074] Weigh 45.0g olive oil and 42.5g turpentine into the reactor, start stirring, add 87.2g gemini surfactant (n=2, R at 400rpm) 1 is ethyl, R 2 be 14 alkyl), 30.0g lauryl polyoxyethylene (6) ether, 40.5g cocamidopropyl betaine, slowly be warming up to 60 ℃ under stirring, stirring reaction 30min, then slowly drip 52.5g isobutanol and 52.0 g water mixture. After the dropwise addition, the reaction was continued to be stirred at 60° C. for 60 min to obtain a transparent nanoemulsion SD-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com