A solid-liquid compound lubrication method for cup-type harmonic gear reducer

A gear reducer and harmonic technology, which is applied in the field of solid-liquid compound lubrication of cup type harmonic gear reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

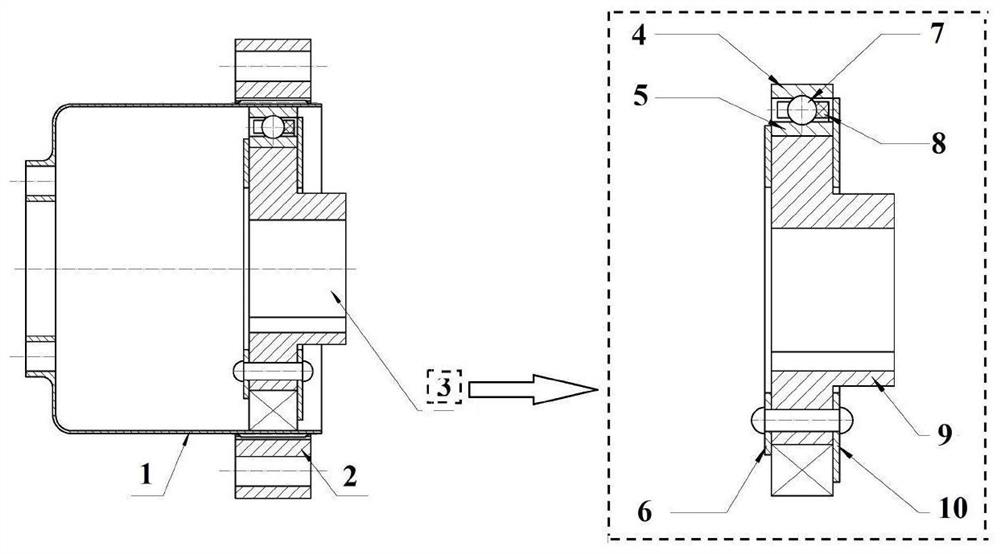

[0046] (1) After splitting the XB1-60-150 type cup-type harmonic gear reducer into rigid wheels, flexible wheels, flexible bearing inner rings, flexible bearing outer rings, flexible bearing steel balls, cams and baffles, the Ultrasonic cleaning was carried out in gasoline and acetone solution, and air-dried to obtain the components to be treated with solid lubrication.

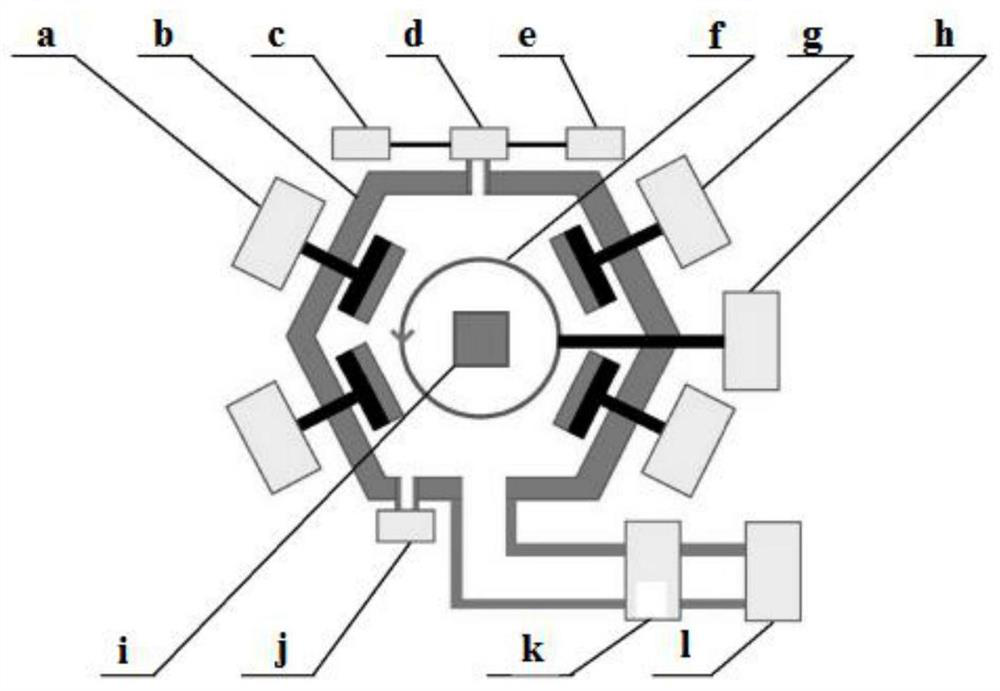

[0047] (2) Matching clean gloves, load the rigid wheel, flexible wheel, flexible bearing inner ring and flexible bearing outer ring to be treated by solid lubrication on the workpiece rack of the coating vacuum chamber, close the door of the vacuum chamber, and turn on the mechanical pump and molecular pump in turn. The vacuum chamber is evacuated to a vacuum degree of 5.0×10 -3 Pa; turn on the argon valve and gas filling valve in turn, fill the vacuum chamber with argon until the partial pressure of argon in the vacuum chamber is maintained at 4Pa; turn on the DC bias power supply, adjust the DC bias value u...

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is that the transition layer and the deposition conditions of the composite film layer are different:

[0061] When the closed-field unbalanced magnetron sputtering method is used to prepare the Cr thin film layer and the WC thin film layer, the sputtering power of the corresponding Cr target and WC target is 4kW, the DC bias voltage is -50V, and the deposition time is 10min. , the rotation speed of the workpiece rack driving motor is 1r / min;

[0062] When plasma-assisted chemical vapor deposition is combined with closed-field unbalanced magnetron sputtering to prepare C-WC composite film layers, the sputtering power of the WC target is 2kW, the DC bias voltage is -500V, the deposition time is 80min, and the workpiece rack The rotation speed of the driving motor is 1r / min.

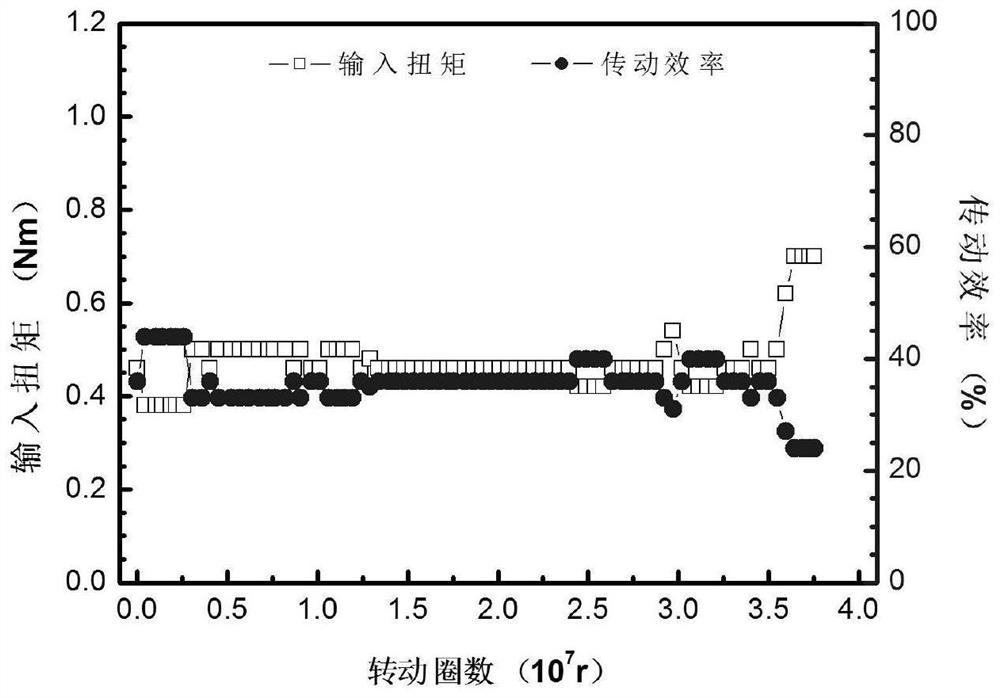

[0063] The carrying capacity of the C-WC composite film layer deposited on the rigid wheel, flexible wheel, flexible bearing inner ring and f...

Embodiment 3

[0067] The difference between this embodiment and embodiment 1 is only that the conditions of film deposition are different:

[0068] When the closed-field unbalanced magnetron sputtering method is used to prepare the Cr film layer and the WC film layer, the sputtering power of the corresponding Cr target and the WC target is 8kW, the DC bias voltage is -200V, and the deposition time is 20min. The rotation speed of the workpiece rack driving motor is 10r / min; when the plasma-assisted chemical vapor deposition is combined with the closed field unbalanced magnetron sputtering method to prepare the C-WC composite thin film layer, the sputtering power of the WC target is 4kW, and the DC bias The voltage is -700V, the deposition time is 90min, and the rotation speed of the workpiece rack driving motor is 10r / min.

[0069] The carrying capacity of the C-WC composite film layer deposited on the rigid wheel, flexible wheel, flexible bearing inner ring and flexible bearing outer ring o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com