Catalyst for preparing hydrogenated terphenyl as well as preparation method and application thereof

A technology for hydrogenation of terphenyls and catalysts, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., and can solve problems such as poor selectivity, low catalytic efficiency of catalysts, and high production costs. problems, to achieve the effect of high selectivity, good promotion and application value, and small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

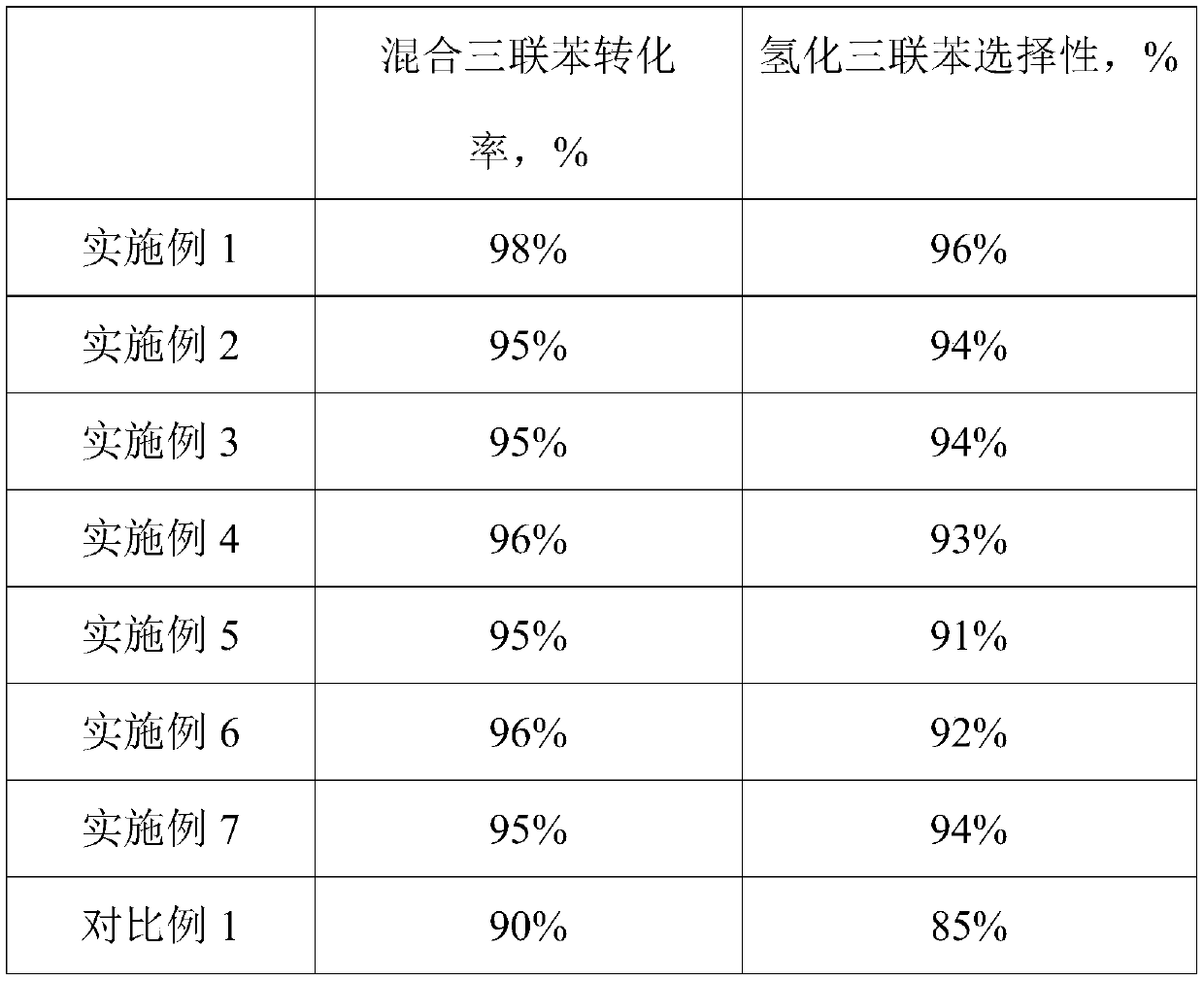

Examples

Embodiment 1

[0066] In the catalyst described in this example, MgO is used as the carrier, NiB compound is the active component, the molar ratio of Ni and B is 2.5, and the mass percentage of NiB compound in the catalyst is 14.79%; the active component is amorphous State form exists, and the particle diameter of described carrier is 270nm; The preparation method of described catalyst comprises the following steps:

[0067] (1) Add 50g of MgO powder to 100mL of AgNO 3 solution (control loading Ag mass fraction is 0.12%), stirred at 313K for 4h, then the sample was suction filtered, and air-dried for 24h to obtain Ag 2 O / MgO spare;

[0068] (2) the Ag in the step (1) of 1.6g 2 O / MgO powder is added in the NiB bath of 150mL (plating bath composition is: 5g / L KBH 4 , 12g / L NiSO 4 ·6H 2 (0, 12g / L ethylenediamine and 22g / L NaOH), then heated and stirred in a 318K water bath for 30min to obtain a black NiB / MgO amorphous catalyst; the catalyst was washed with deionized water to neutrality and...

Embodiment 2

[0072] In the catalyst described in this example, MgO is used as the carrier, NiB compound is the active component, the molar ratio of Ni and B is 2.5, and the mass percentage of NiB compound in the catalyst is 14.79%; the active component is amorphous State form exists, and the particle diameter of described carrier is 280nm; The preparation method of described catalyst comprises the following steps:

[0073] (1) Add 50g of MgO powder to 100mL of AgNO 3 solution (control loading Ag mass fraction is 0.12%), stirred at 313K for 4h, then the sample was suction filtered, and air-dried for 24h to obtain Ag 2 O / MgO spare;

[0074] (2) the Ag in the step (1) of 1.6g 2 O / MgO powder is added in the NiB bath of 150mL (plating bath composition is 5g / L KBH 4 , 12g / L NiSO 4 ·6H 2 (0, 16g / L ethylenediamine and 35g / L NaOH). Then heated and stirred in a 318K water bath for 30 minutes to obtain a black NiB / MgO amorphous catalyst; the catalyst was washed with deionized water until neutra...

Embodiment 3

[0077] In the catalyst described in this example, MgO is used as the carrier, NiB compound is the active component, the molar ratio of Ni and B is 2.82, and the mass percentage of NiB compound in the catalyst is 12.31%; the active component is amorphous State form exists, and the particle diameter of described carrier is 290nm; The preparation method of described catalyst comprises the following steps:

[0078] (1) Add 50g of MgO powder to 100mL of AgNO 3 solution (control loading Ag mass fraction is 0.12%), stirred at 313K for 4h, then the sample was suction filtered, and air-dried for 24h to obtain Ag 2 O / MgO spare;

[0079] (2) the Ag in the step (1) of 1.6g 2 O / MgO powder was added to 150mL of NiB plating solution (the composition of the plating solution was 2g / L KBH 4 , 12g / L NiSO 4 ·6H 2 (0, 16g / L ethylenediamine and 35g / L NaOH), then heated and stirred in a 318K water bath for 30min to obtain a black NiB / MgO amorphous catalyst, and the catalyst was washed with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com