Vertical aluminum-iron continuous casting machine mold processing device and method

A mold processing and continuous casting machine technology, applied in the direction of feeding device, metal processing equipment, metal processing machinery parts, etc., can solve the problems of easily damaged continuous casting machine mold body, increase processing steps, poor grinding effect, etc., and achieve simple structure , avoid drilling, easy demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

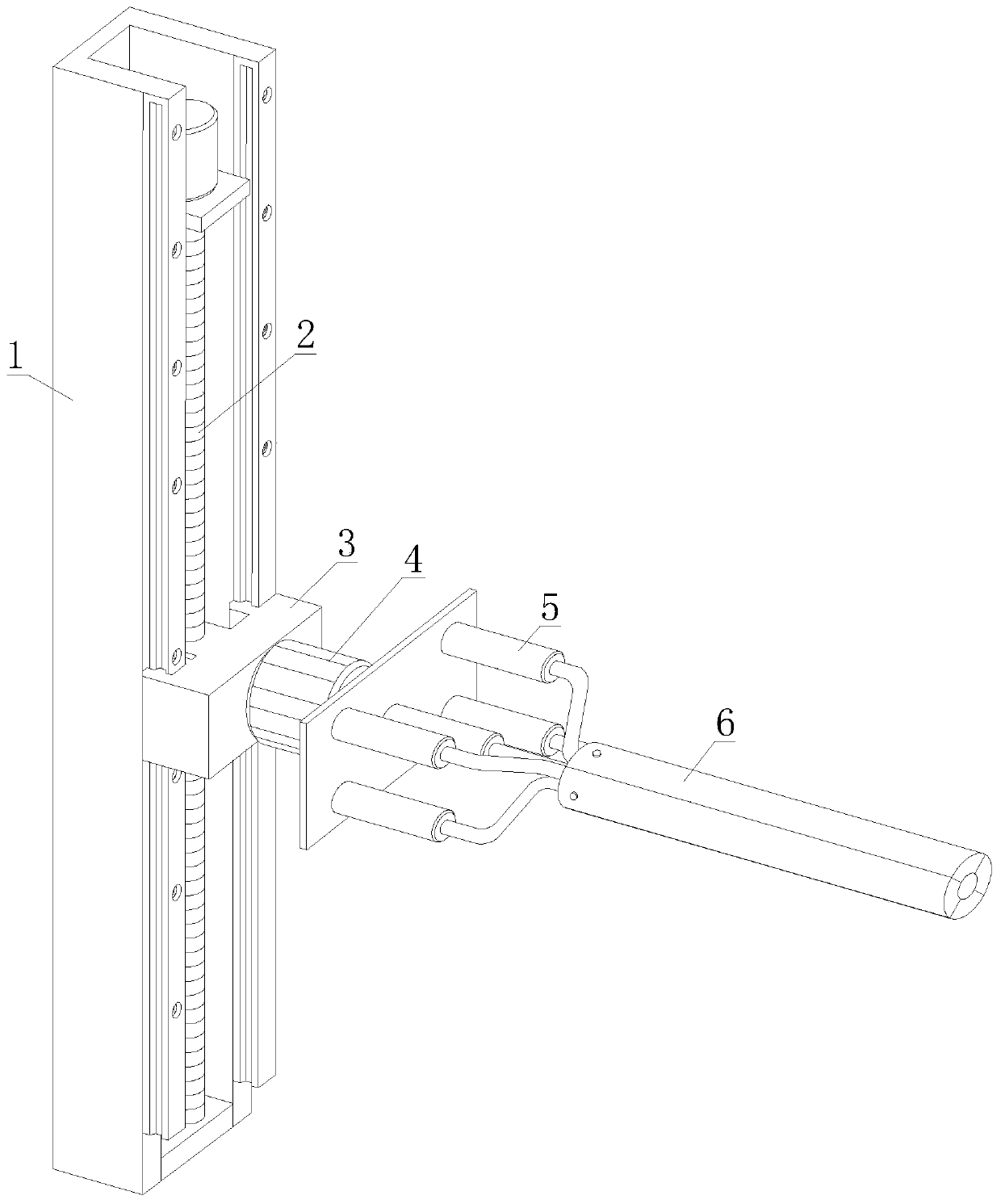

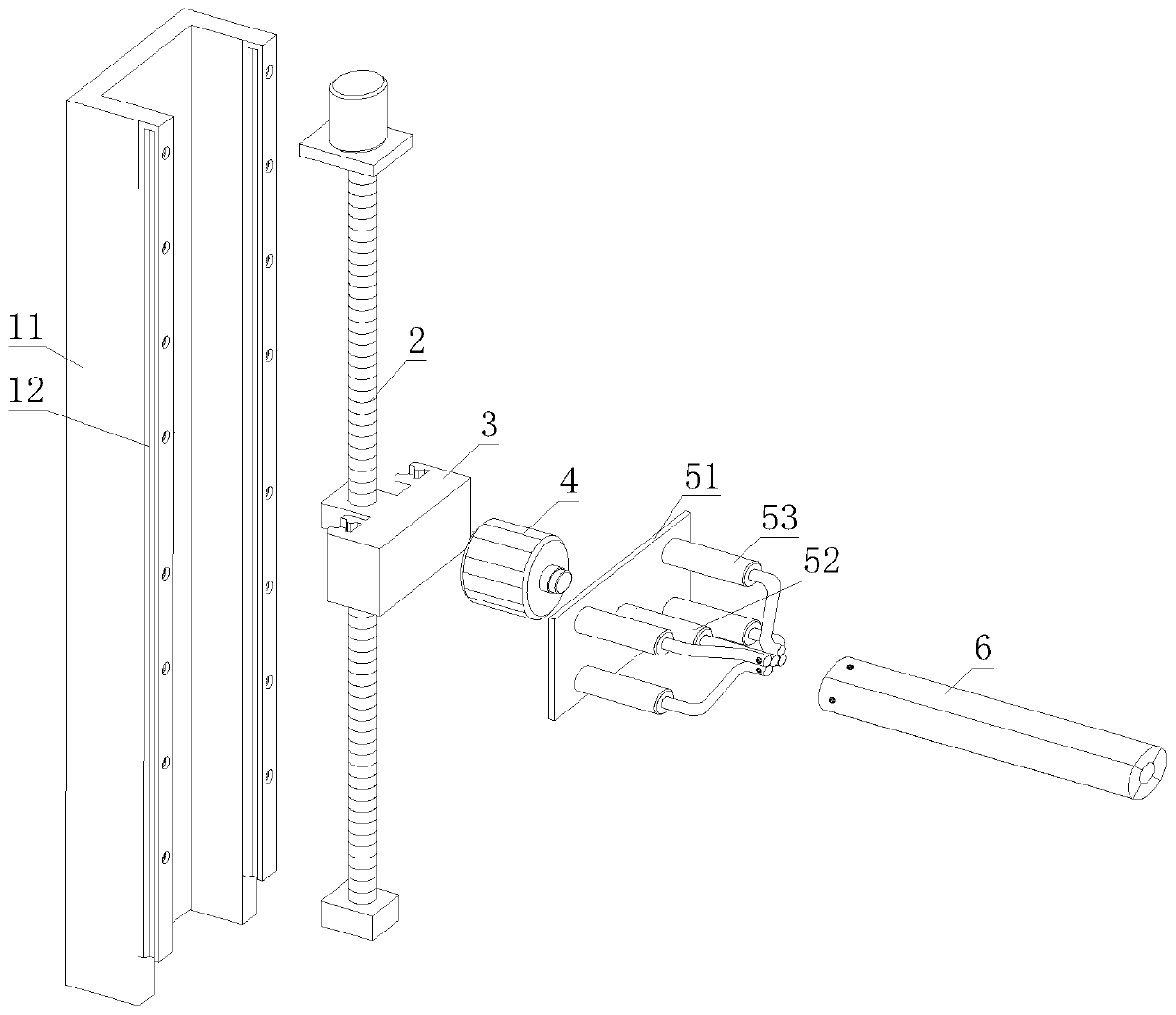

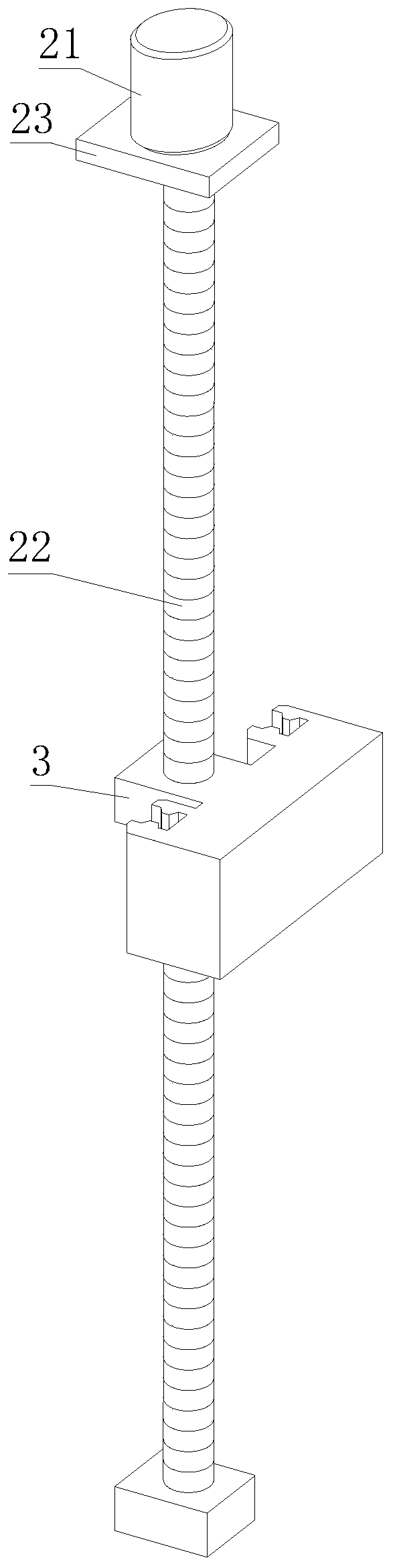

[0032] refer to Figure 1-3 , a mold processing device for a vertical aluminum-iron continuous casting machine, comprising a support 1, a lifting mechanism 2, an E-shaped slider 3, a rotating motor 4, a telescopic mechanism 5 and a rod body 6, and the middle part of the support 1 is fixedly connected with a lifting mechanism 2. An E-type slider 3 is slidably connected to the support 1. The lifting mechanism 2 includes a drive motor 21, a ball screw 22 and an end plate 23. Both ends of the ball screw 22 are connected to the end plate 23 through bearing rotation. Both end plates 23 are fixedly connected with the support 1, and a driving motor 21 is installed on the end plate 23 at the upper end of the ball screw 22. The driving motor 21 is connected with the ball screw 22, and the ball screw 22 is composed of a screw rod and a screw rod. The screw nut is connected with the E-type slider 3. The lifting mechanism 2 drives the E-type slider 3 to slide and lift along the support 1. ...

Embodiment 2

[0041] refer to Figure 7 , the number of the auxiliary cylinder assembly 53 and the auxiliary rod 62 is four, and the main rod 61 and the auxiliary rod 62 are closed to form an arc cylinder.

[0042] refer to Figure 8 , in order to better demonstrate the mold processing process of the vertical aluminum-iron continuous casting machine, this embodiment now proposes a processing method for the mold processing device of the vertical aluminum-iron continuous casting machine, including the following steps:

[0043] S101: select the rod body 6 with a smooth surface, and insert the rod body 6 into the mold cavity of the prefabricated continuous casting machine mold; Open an insertion hole, and the rod body 6 is inserted to a certain depth along the hole, so that the rod body 6 is in the same position as the deep hole;

[0044] S102: After the continuous casting machine mold is formed, first pull out the main rod 61, and then pull out the auxiliary rod 62 to obtain a deep hole; whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com