Chopped carbon fiber reinforced resin binder-ultrahard abrasive grinding wheel and preparation method thereof

A short-cut carbon fiber, super-hard abrasive technology, applied in abrasives, grinding/polishing equipment, grinding devices, etc., can solve problems such as affecting the service life of grinding wheels, poor temperature resistance of grinding wheels, affecting processing efficiency, etc., to save energy. , The effect of reducing production cost and maintaining grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A chopped carbon fiber reinforced resin bonded superabrasive grinding wheel, the preparation method of which is aluminum powder matrix mixing, grinding layer mixing, aluminum powder matrix molding pressing, grinding layer molding pressing, hot pressing sintering, and secondary hardening .

[0055] (1) Aluminum powder matrix mixture:

[0056]

[0057]Among them, the size of aluminum powder is 320 mesh; the carbon content of chopped carbon fiber is 96%; the tensile strength is 3600MPa; the tensile modulus is 320GPa; the density is 1.755 g / cm 3 ; Diameter 7.5μm; Length range: 1~10mm chopped carbon fiber.

[0058] Weigh the aluminum powder, ferric oxide powder, calcium oxide powder and chopped carbon fiber according to the above ratio, put them in a three-dimensional mixer, mix for 1.5 hours, and then ball mill for 1.5 hours to obtain aluminum powder.

[0059] (2) Grinding layer mixing:

[0060] First, according to weight percentage, phenolic resin 80%, polyimide resi...

Embodiment 2

[0075] A chopped carbon fiber reinforced resin bonded superabrasive grinding wheel, the preparation method of which is aluminum powder matrix mixing, grinding layer mixing, aluminum powder matrix molding pressing, grinding layer molding pressing, hot pressing sintering, and secondary hardening .

[0076] (1) Aluminum powder matrix mixture:

[0077]

[0078] Among them, the carbon content of chopped carbon fiber is 96%; the tensile strength is 3600MPa; the tensile modulus is 320GPa; the density is 1.755 g / cm 3 ; Diameter 7.5μm; Length range: 1~15mm chopped carbon fiber.

[0079] According to the above ratio, weigh the aluminum powder, ferric oxide, calcium oxide and chopped carbon fiber, pre-mix them manually, then put them in a three-dimensional mixer, mix them for 1.5 hours, make them fully mixed and then ball mill them for 1.5 hours. Aluminum powder is obtained.

[0080] (2) Grinding layer mixing:

[0081] First, according to weight percentage, phenolic resin 75%, pol...

Embodiment 3

[0095] Processing performance test:

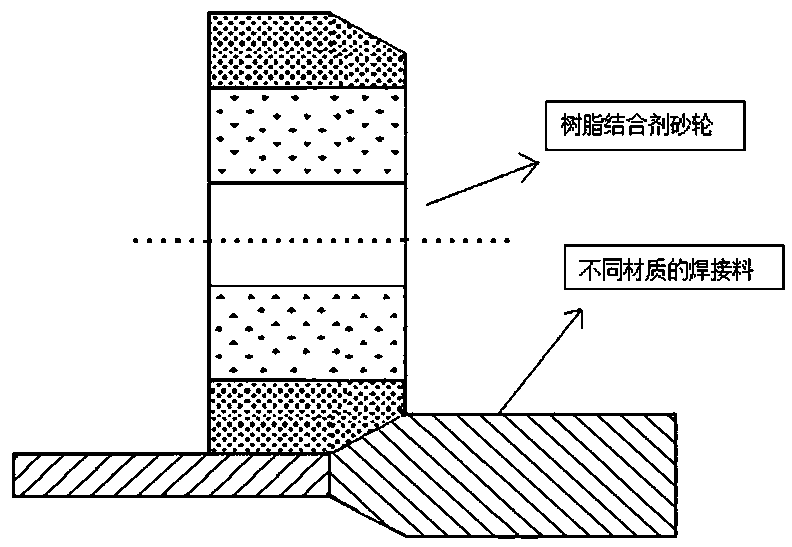

[0096] Table 1 compares the performance parameters of the same solder workpiece processed by the chopped carbon fiber reinforced resin bond grinding wheel of the present invention and the existing grinding wheel, wherein the chopped carbon fiber reinforced resin bond grinding wheel 1 is the grinding wheel in the first embodiment, image 3 A schematic diagram of the processing. The better the shape retention of the grinding wheel, the faster the limit speed of the grinding wheel. When processing the same type of solder, the faster the speed of the grinding wheel, the higher the processing efficiency; the longer the dressing interval of the grinding wheel, the lower the dressing frequency, and the processing efficiency of the grinding wheel is also improved. ;The higher the heat that the grinding wheel can withstand, the less likely the grinding wheel will be burned. When processing the same type of solder, when the number of processed workp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com