Preparation method of graphdiyne-loaded monatomic catalyst

A graphdiyne and catalyst technology, which is applied in the field of preparing single-atom catalysts, can solve problems such as inability to single-atom catalysts, unstable metal single atoms and support materials, atomic agglomeration and damage to the support structure, and achieve excellent oxygen reduction reaction and preparation speed. Fast, simple and convenient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

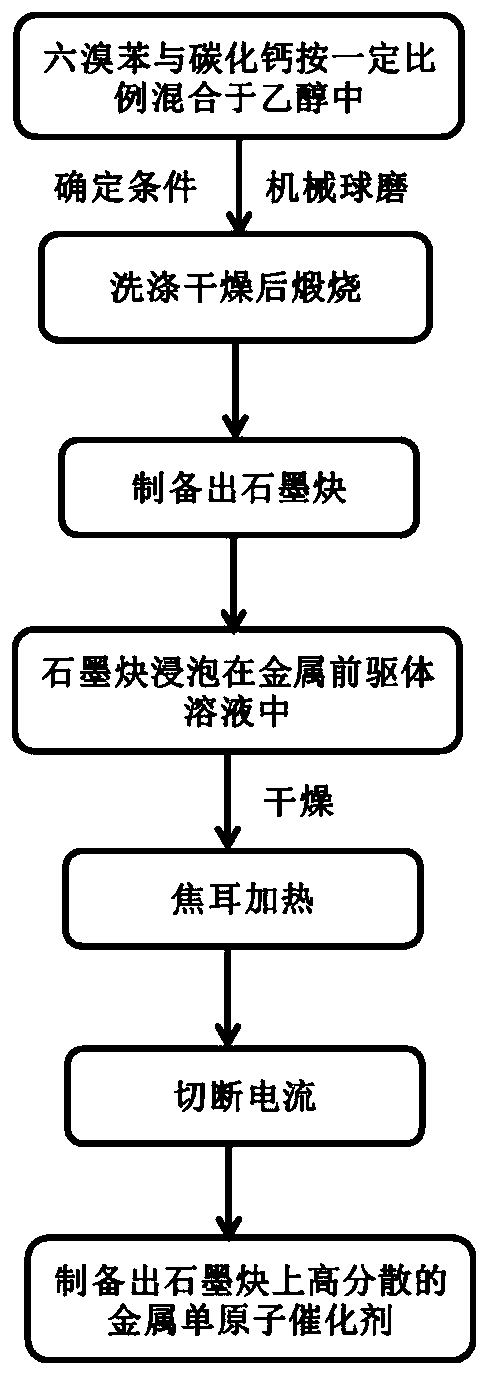

[0041] The invention provides a preparation method of a graphyne-supported single-atom catalyst, such as figure 1 shown, including the following steps:

[0042] Step 1. Mix hexabromobenzene and calcium carbide at a molar ratio of 1:3 to 1:6, mix well and dissolve in ethanol to form an ethanol solution; wherein, the molar ratio of hexabromobenzene and ethanol is 10:1- 25:1; the volume of ethanol is 10-20ml, put the ethanol solution and a certain amount of stainless steel balls into a ball mill for grinding.

[0043] It should be noted that the ball mill was used to process at a rotational speed of 600 rpm for 40-48 hours; and during the grinding process, cooling was performed every 30 minutes for 15 minutes to avoid overheating. The purpose of grinding the ethanol solution with stainless steel balls and controlling the grinding time is to reduce the powder agglomeration, ball sticking, sticking to the wall and the wear degree of the grinding medium and the inner wall of the gr...

Embodiment 1

[0056] The present embodiment provides a kind of preparation method of graphyne supported single-atom catalyst, comprising the following steps:

[0057] Step 1. Mix hexabromobenzene and calcium carbide in 10ml ethanol at a ratio of 1:5, put it and 67g stainless steel balls into a ball mill for grinding;

[0058] Step 2. After the grinding is completed, perform centrifugal washing, dry in a vacuum oven, and then calcinate at 450° C. for 2 hours;

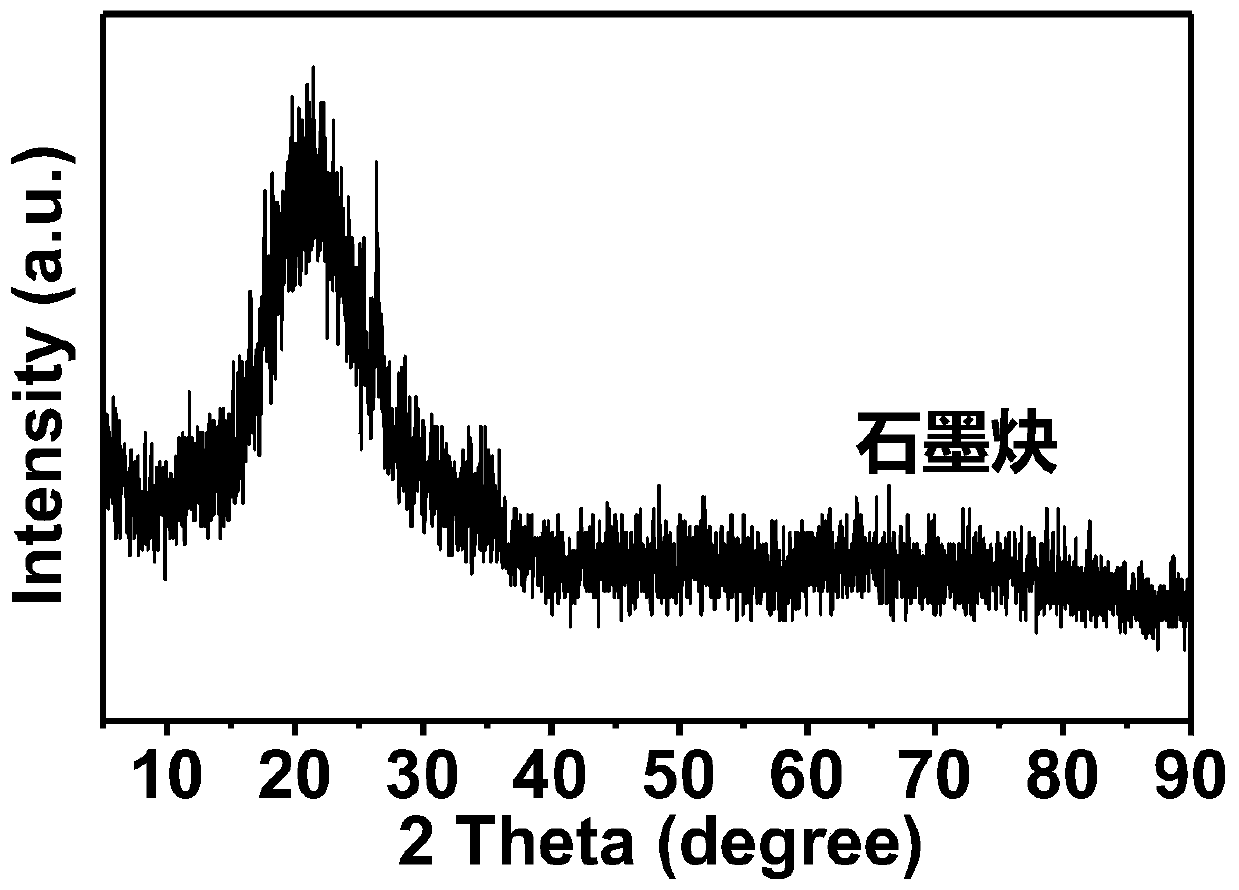

[0059] Step 3, preparing graphyne after acid washing the calcined product;

[0060] Step 4, configure 25mL 0.02mol / L metal precursor solution, wherein the metal precursor is PdCl 2 , the solvent is water; after mixing the prepared graphdiyne and the metal precursor solution for 24 hours, filter, wash with deionized water for 2 to 3 times, and dry in a vacuum oven at 60°C for 6 hours;

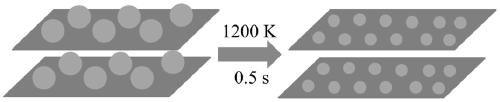

[0061] Step 5: Treat the graphyne loaded with the metal precursor with Joule heating to a high temperature of 1000K, and then cut off the current to ...

Embodiment 2

[0064] The present embodiment provides a preparation method of a graphyne-supported single-atom catalyst, comprising the following steps: Step 1, mixing hexabromobenzene and calcium carbide in 10ml ethanol at a ratio of 1:5, and putting it with 67g stainless steel balls into the ball mill for grinding;

[0065] Step 2. After the grinding is completed, perform centrifugal washing, dry in a vacuum oven, and then calcinate at 450° C. for 2 hours;

[0066] Step 3, preparing graphyne after acid washing the calcined product;

[0067] Step 4, configure 20mL 0.01mol / L metal precursor solution, wherein the metal precursor is H 3 PtCl 6 , the solvent is water; after mixing the prepared graphdiyne and the metal precursor solution for 24 hours, filter and wash with deionized water for 2 to 3 times, and dry in a vacuum oven at 60°C for 6 hours;

[0068] Step 5: Treat the graphyne loaded with the metal precursor to a high temperature with Joule heating, and then cut off the current to co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com