Solid electrolyte membrane of lithium-sulfur battery, preparation method of solid electrolyte membrane and lithium-sulfur battery

A solid-state electrolyte membrane and lithium-sulfur battery technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, solid electrolytes, etc., can solve problems such as metal lithium deactivation, active material loss, and increased electrolyte viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

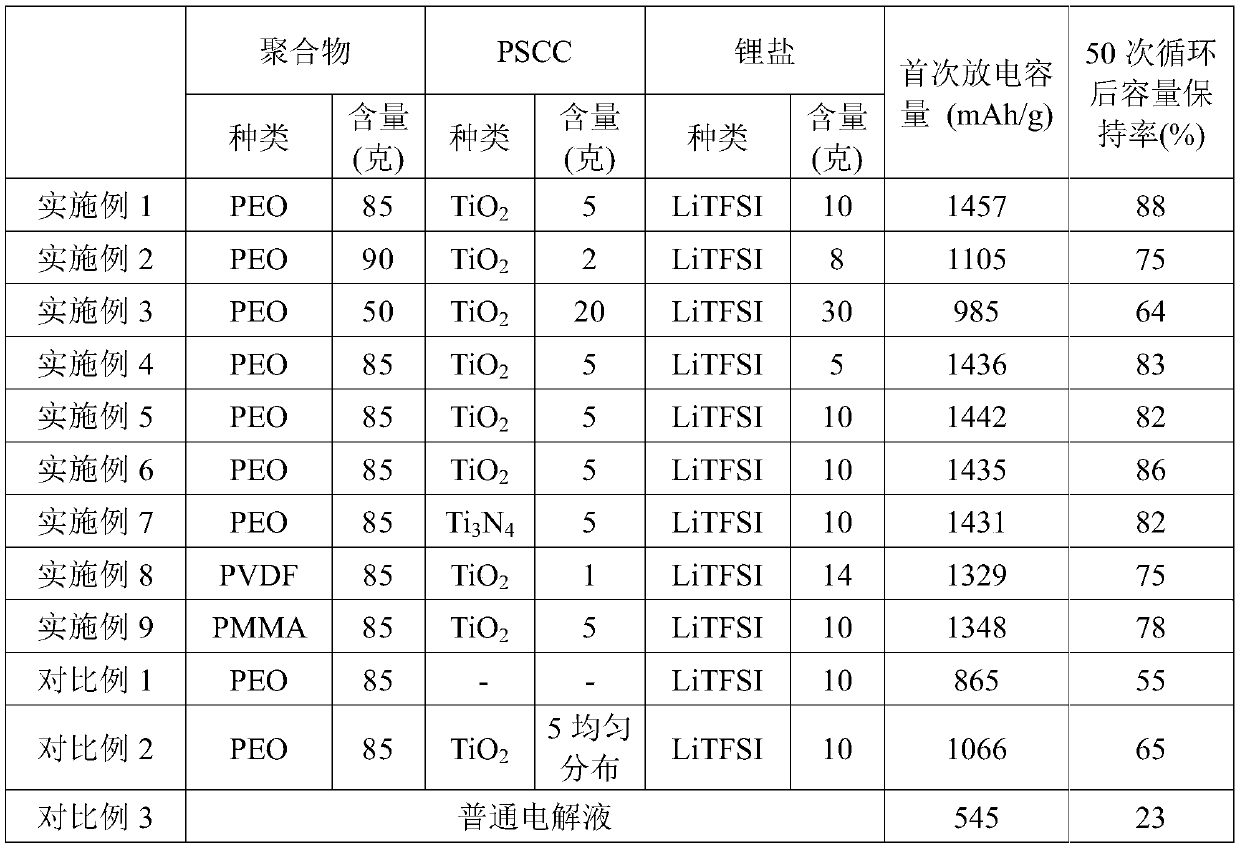

Embodiment 1

[0030] Dissolve 85g of PEO (molecular weight: 200,000) in 1000ml of acetonitrile, stir at 40°C for 24h, then add 5g of TiO 2 Particles and 10g of LiTFSI salt were stirred and dispersed for 2 hours to obtain a composite electrolyte emulsion. Coat it on the PTFE substrate while it is hot, the coating thickness is 100μm, after standing at 40°C for 48h, place it in a place filled with CaCl 2 Dry in a desiccator for 24 hours. Then vacuum-dry at 80° C. for 72 hours, and place it in a phosphorus pentoxide dryer for 72 hours to obtain a solid electrolyte membrane.

Embodiment 2

[0032] Dissolve 90g of PEO (molecular weight: 200,000) in 1000ml of acetonitrile, stir at 40°C for 24h, then add 2g of TiO2 Particles and 8g LiTFSI salt were stirred and dispersed for 2 hours to obtain a composite electrolyte emulsion. Coat it on the PTFE substrate while it is hot, the coating thickness is 100μm, after standing at 40°C for 48h, place it in a place filled with CaCl 2 Dry in a desiccator for 24 hours. Then vacuum-dry at 80° C. for 72 hours, and place it in a phosphorus pentoxide dryer for 72 hours to obtain a solid electrolyte membrane.

Embodiment 3

[0034] Dissolve 50g of PEO (molecular weight: 200,000) in 1000ml of acetonitrile, stir at 40°C for 24h, then add 20g of TiO 2 Particles and 30g LiTFSI salt were stirred and dispersed for 2 hours to obtain a composite electrolyte emulsion. Coat it on the PTFE substrate while it is hot, the coating thickness is 100μm, after standing at 40°C for 48h, place it in a place filled with CaCl 2 Dry in a desiccator for 24 hours. Then vacuum-dry at 80° C. for 72 hours, and place it in a phosphorus pentoxide dryer for 72 hours to obtain a solid electrolyte membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com