Hydrophilic modified plant fiber cat litter material and preparation method thereof

A technology of plant fiber and hydrophilic modification, which is applied in the field of pets to achieve the effects of large stock, improved water absorption performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

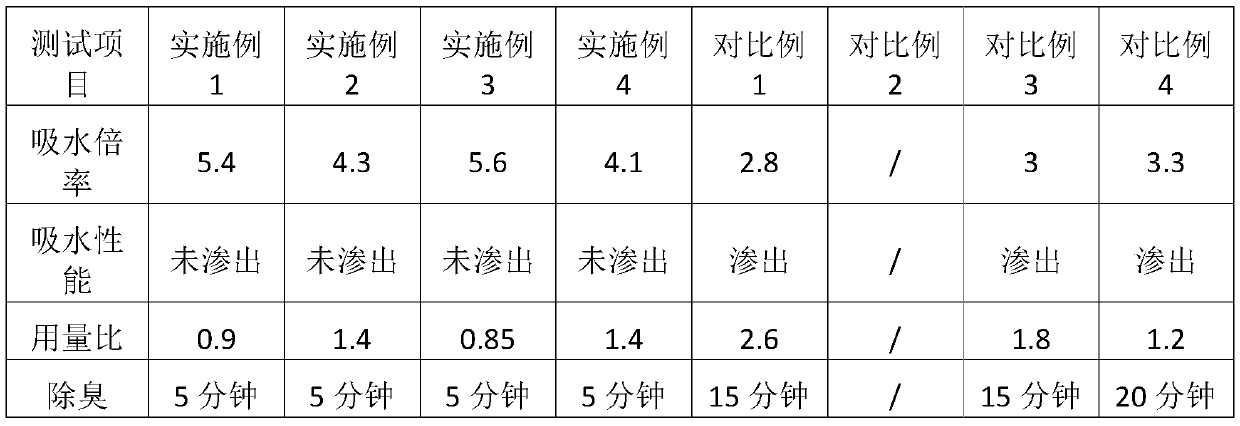

Examples

Embodiment 1

[0025] Select poplar as the base material, mechanically crush the poplar wood to 40-60 meshes, add water to soak for 12 hours according to the base material: water mass ratio of 1:2, and use a straw puffing machine (the manufacturer is the Energy Research Institute of Liaoning Province, model It is LNSNYS-P01, the same below) for puffing treatment; configure 10% sodium hydroxide solution, spray the stain according to the mass ratio of raw materials: sodium hydroxide solution 4:1, and carry out alkalization treatment for 8 hours; take 1kg of alkalization treatment Add 2kg of deionized water to the sample, heat to 50°C and stir evenly at a constant temperature, then add 5g of initiator sodium persulfate, stir evenly, then add 100g of acrylic acid, stir again for 5 minutes, and add 1g of crosslinking agent N, N-sub Methylbisacrylic acid amine, stirred and reacted for 2 hours, squeezed and filtered to remove excess water, dried at 90°C to make the water content of the sample 8%, me...

Embodiment 2

[0028] Choose wheat straw as the base material, mechanically crush the wheat straw to 40-60 mesh, add water to soak for 12 hours according to the base material: water mass ratio of 2:1, and use straw extruder for puffing treatment; configure 15% sodium hydroxide Solution, according to the mass ratio of raw materials: sodium hydroxide solution 1:1, spray and moisten, and carry out alkalization treatment for 8 hours; take 1kg of alkalization-treated samples, add 2kg of deionized water, heat to a temperature of 50°C and stir evenly, then add 5g of initiator potassium persulfate, stir well and then add 150g of acrylic acid, stir again for 5 minutes, add 1g of crosslinking agent N-N,-methylenebisacrylic acid amine again, stir and react for 2 hours, squeeze and filter to remove excess water, 90 ℃ drying treatment, so that the water content of the sample is 8%, mechanically pulverized again, and sieved to obtain the hydrophilic modified wheat straw with a particle size of 100 mesh to ...

Embodiment 3

[0031] Choose peanut shells as the base material, crush the peanut shells mechanically to 40-60 meshes, add water to soak for 12 hours according to the base material: water mass ratio of 1:2, and use a straw extruder for puffing treatment; prepare 10% ammonia solution, According to the mass ratio of raw materials: ammonia solution 3:1, spray and moisten the stains, and carry out alkalization treatment for 8 hours; take 1kg of alkalization-treated samples, add 2kg of deionized water, heat to a temperature of 50°C and stir evenly at a constant temperature, then add 3g of initiator to pass Ammonium sulfate, stir well, then add 80g of acrylic acid, stir again for 5 minutes, add 0.5g of cross-linking agent diisocyanate again, stir and react for 2 hours, squeeze and filter to remove excess water, and dry at 90°C to make the water content of the sample 8%, mechanically pulverized again, and sieved to obtain hydrophilic modified peanut shell fibers with a particle size of 100 mesh to 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com