Device and method for preparing epoxidized soybean oil

A technology of epoxidized soybean oil and reaction device, which is applied in chemical instruments and methods, control/adjustment processes, chemical/physical/physical-chemical stationary reactors, etc., can solve problems such as low production efficiency, and achieve improved utilization, The effect of improving production efficiency and improving the degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

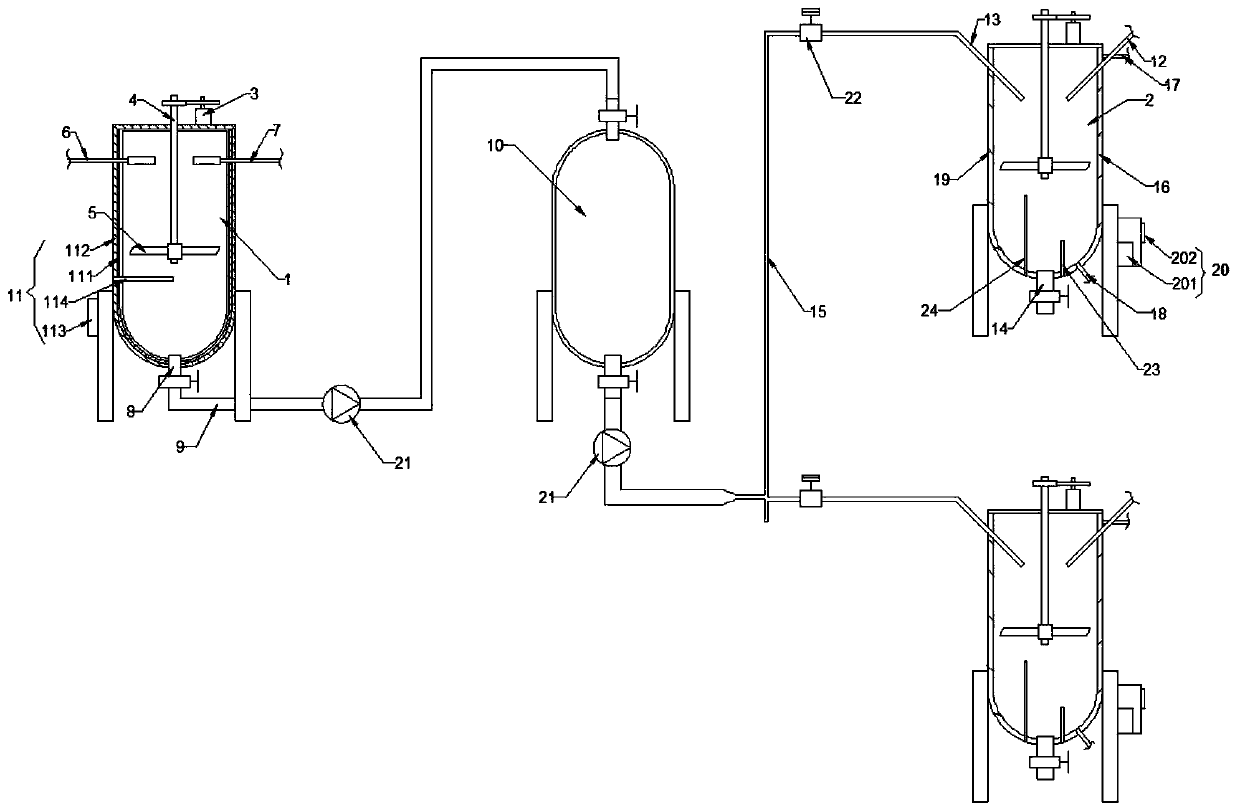

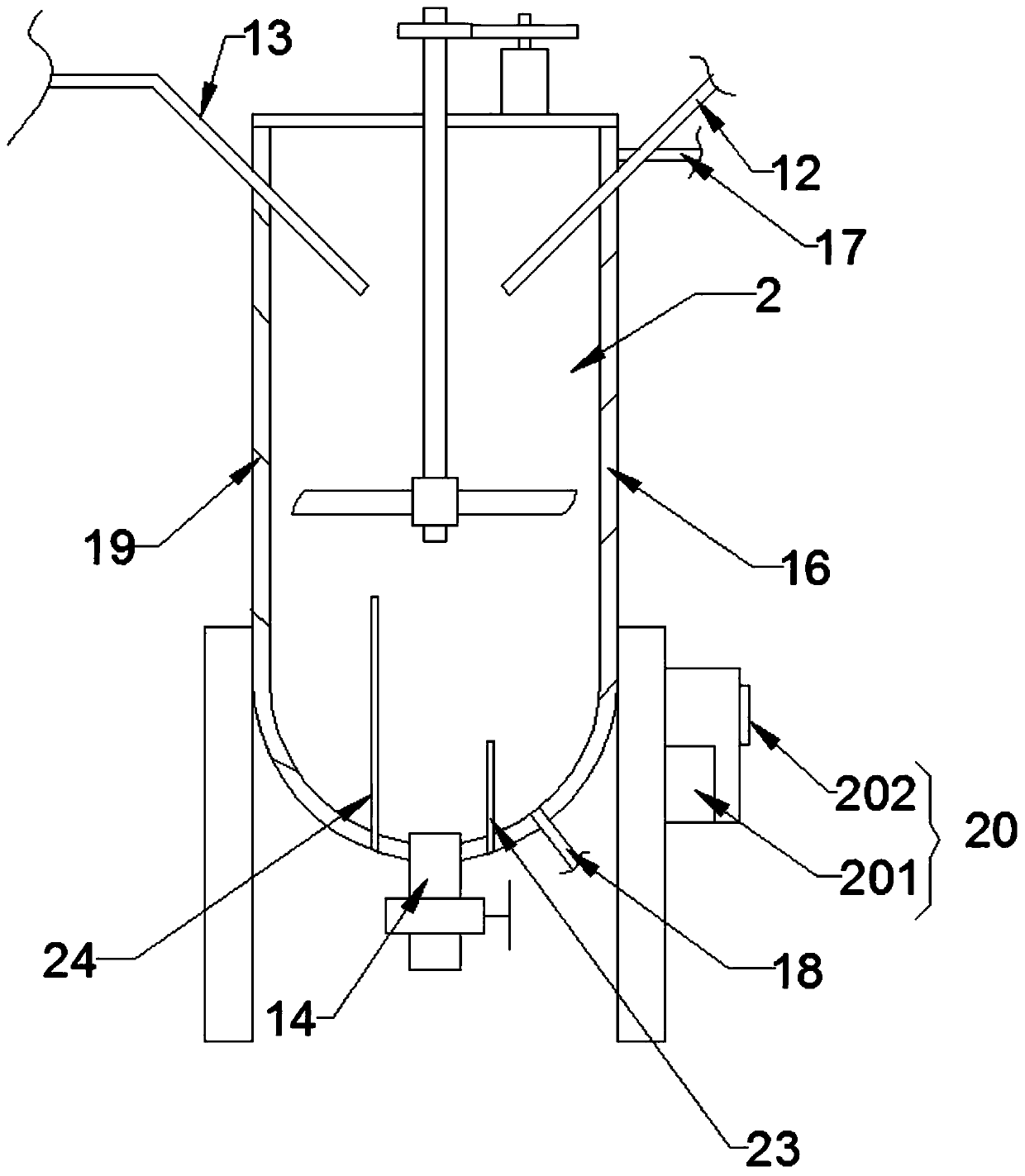

[0038] This embodiment, as a basic embodiment of the present invention, discloses a continuous reaction device for preparing epoxidized soybean oil. The specific structure is as follows figure 1 and image 3As shown, it includes a heating reactor 1 and a plurality of heat preservation reactors 2, wherein the top of the heating reactor 1 is provided with a stirring motor 3 and a stirring shaft 4 which are dynamically connected to each other, and one end of the stirring shaft 4 goes deep into the heating reactor 1 inside, and is fixedly connected with the stirring paddle 5, and at the same time, a grease feed port 6 and an organic acid feed port 7 are arranged on the upper part of the heating reactor 1, and a discharge port 8 is provided at the bottom thereof, and the discharge port 8 passes through The feeding pipe 9 is connected to the inlet end of the buffer storage tank 10, and the material delivery between the heating reactor 1 and the buffer storage tank 2 can be realized ...

Embodiment approach 2

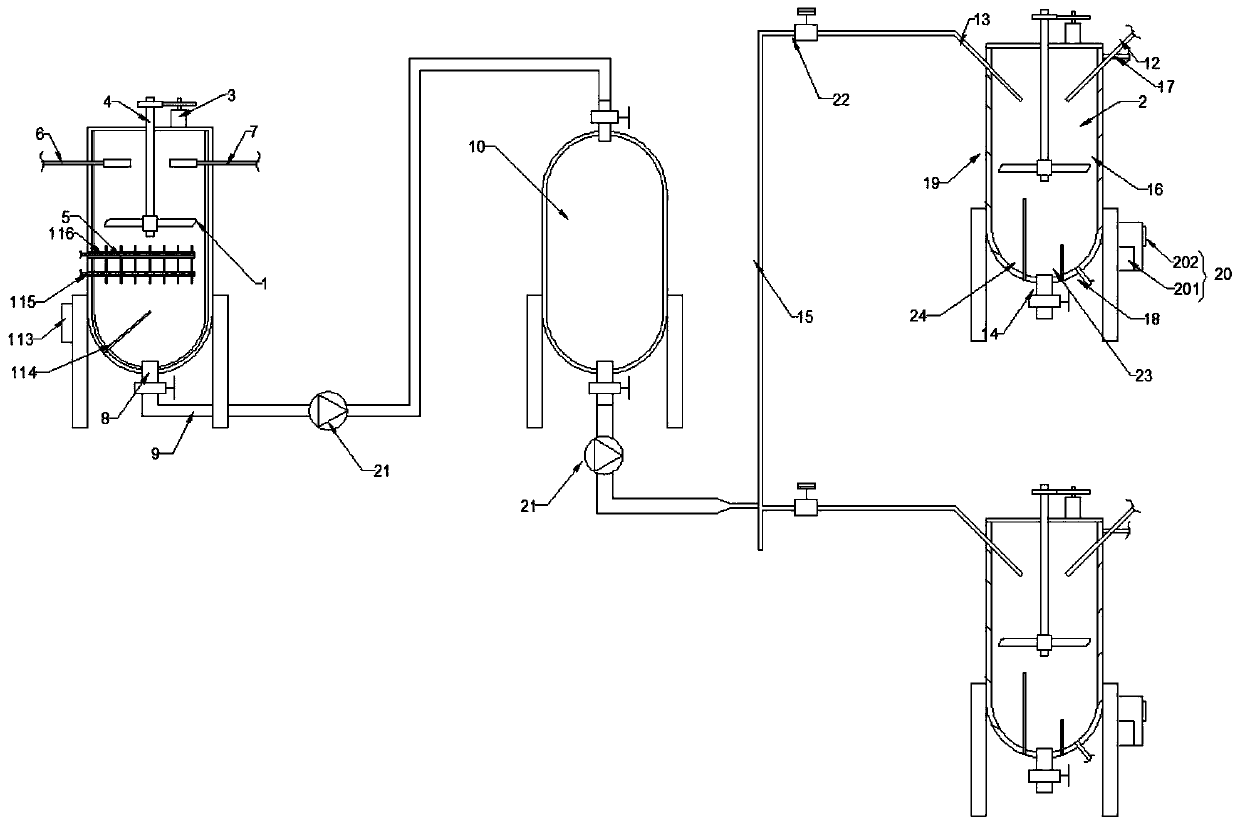

[0043] This embodiment, as a preferred embodiment of the present invention, discloses a continuous reaction device for preparing epoxidized soybean oil. The specific structure is as follows: figure 2 and image 3 As shown, it includes a heating reactor 1 and a plurality of heat preservation reactors 2, the outlet end of the heating reactor 1 is connected with a buffer storage tank 20 through a delivery pump 21, and the outlet end of the buffer storage tank 20 is also connected with a delivery pump 21. The outlet end of the delivery pump 21 is respectively connected to a plurality of feeding branch pipes 15, and each feeding branch pipe 15 is connected to a thermal insulation reaction kettle 2; the heating reaction kettle 1 is provided with a plurality of heating pipes 116 inserted into it One end of the heating tube 116 located in the heating reaction kettle 2 is a closed structure, and the other end is connected to the outside world. A heating rod 115 is fixedly arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com