Polyaniline-gold composite material, and preparation and application thereof

A composite material, polyaniline technology, applied in catalyst activation/preparation, organic compound/hydride/coordination complex catalysts, electrodes, etc. The effect of good synergy, suitable gold loading, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

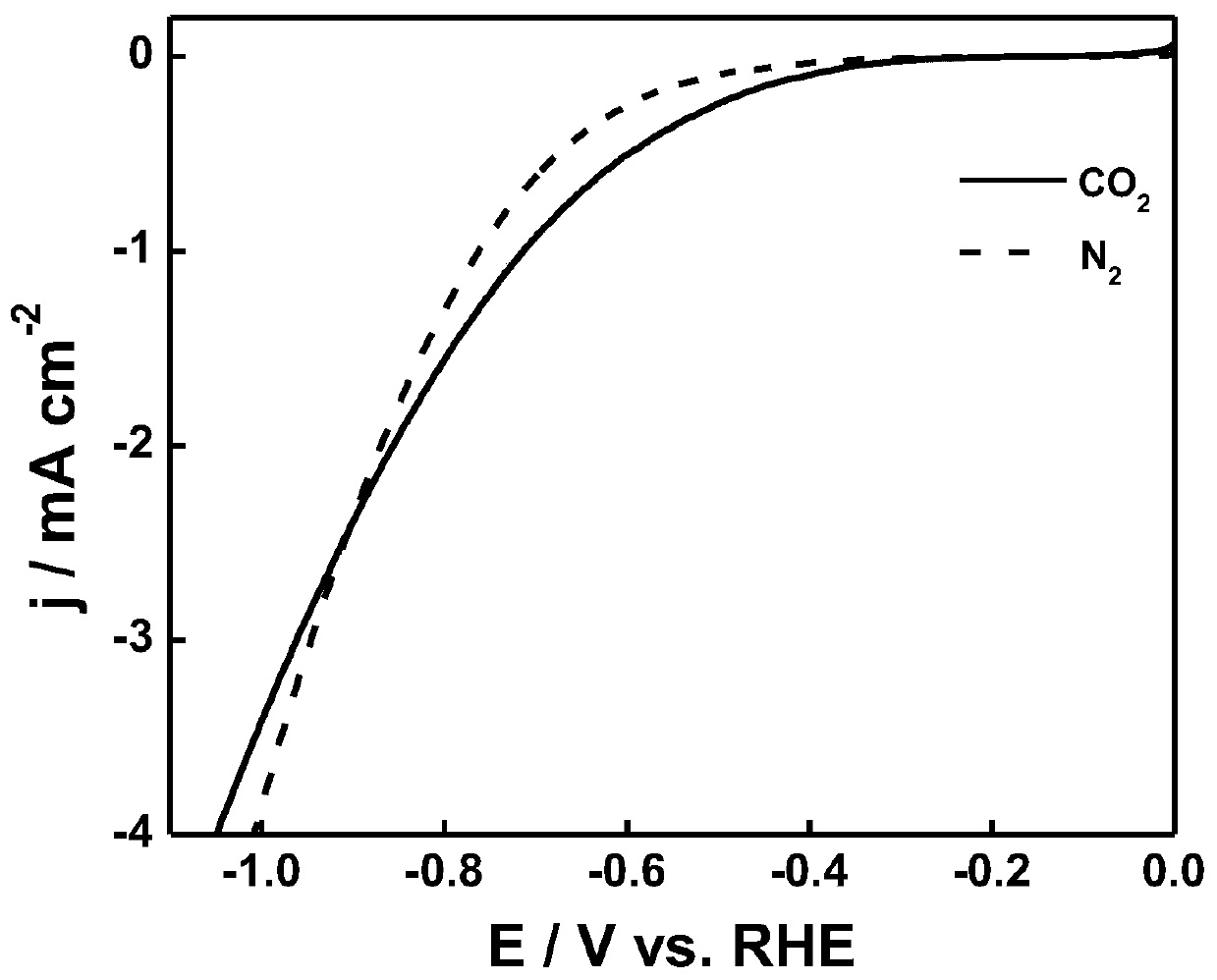

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

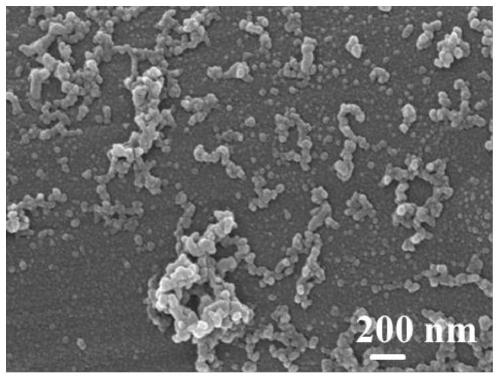

[0032] A preparation method of polyaniline-gold composite material, comprising the steps of:

[0033] (1) Ultrasonic-clean the hydrophilic carbon paper with a thickness of 0.2mm in deionized water, ethanol, and deionized water respectively for 10 minutes each; install the cleaned hydrophilic carbon paper on the platinum electrode holder as the working electrode 1. The geometric size of the working electrode is 1cm×1cm; the platinum sheet is used as the counter electrode, and the geometric size is 1cm×1cm; the saturated calomel electrode (SCE) is used as the reference electrode and placed in the electrolytic cell;

[0034] (2) prepare the mixed solution of aniline and sulfuric acid, wherein the concentration of aniline is 0.05mol / L, and the concentration of sulfuric acid is 0.05mol / L; Cyclic voltammetry (CV) was used to redox the polyaniline template. The starting potential of cyclic voltammetry was -0.1V, the ending potential was 0.9V, the number of scanning cycles was 15, and...

Embodiment 2

[0042] A preparation method of polyaniline-gold composite material, comprising the steps of:

[0043] (1) Ultrasonic-clean the hydrophilic carbon paper with a thickness of 0.2mm in deionized water, ethanol, and deionized water respectively for 10 minutes each; install the cleaned hydrophilic carbon paper on the platinum electrode holder as the working electrode ; Place the platinum mesh as the counter electrode and the saturated calomel electrode (SCE) as the reference electrode in the electrolytic cell;

[0044] (2) prepare the mixed solution of aniline and sulfuric acid, wherein the concentration of aniline is 0.05mol / L, and the concentration of sulfuric acid is 0.1mol / L; Cyclic voltammetry (CV) redox preparation of polyaniline template. The starting potential of cyclic voltammetry is -0.2V, the ending potential is 0.9V, the number of scanning cycles is 30, and the scanning speed is 50mV / s.

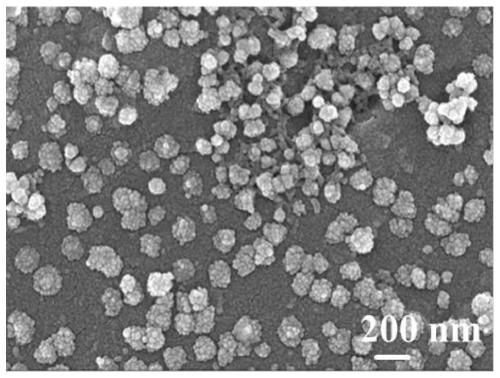

[0045] (3) Prepare a chloroauric acid solution with a concentration of 1 mmol / L; ...

Embodiment 3

[0050] A preparation method of polyaniline-gold composite material, comprising the steps of:

[0051] (1) Ultrasonic-clean the hydrophilic carbon paper with a thickness of 0.2mm in deionized water, ethanol, and deionized water respectively for 10 minutes each; install the cleaned hydrophilic carbon paper on the platinum electrode holder as the working electrode ;Put the platinum wire as the counter electrode and the saturated calomel electrode (SCE) as the reference electrode, and place it in the electrolytic cell;

[0052] (2) prepare the mixed solution of aniline and sulfuric acid, wherein the concentration of aniline is 0.08mol / L, and the concentration of sulfuric acid is 0.05mol / L; Cyclic voltammetry (CV) redox preparation of polyaniline template. The starting potential of cyclic voltammetry is -0.2V, the ending potential is 1.0V, the number of scanning cycles is 20, and the scanning speed is 50mV / s.

[0053] (3) Prepare a chloroauric acid solution with a concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com