Wheat flour processing production line and technical process thereof

A technology of wheat flour and production line, which is applied in application, grain processing, grain milling, etc. It can solve the problems of secondary pollution of products, inability to efficiently impregnate wheat, and poor stirring effect of stirring blades, etc., and achieve the effect of improving the effect of impregnating water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

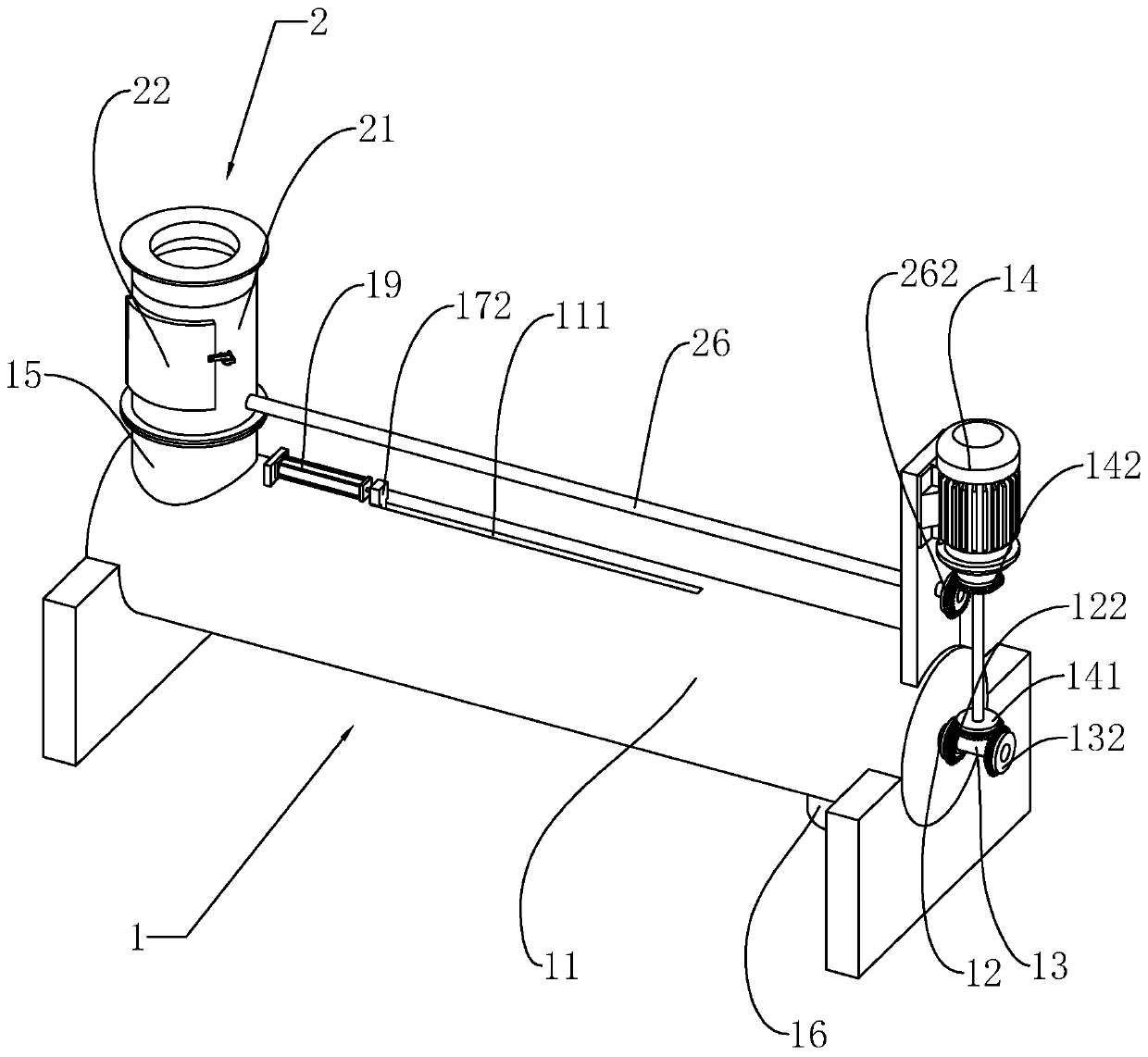

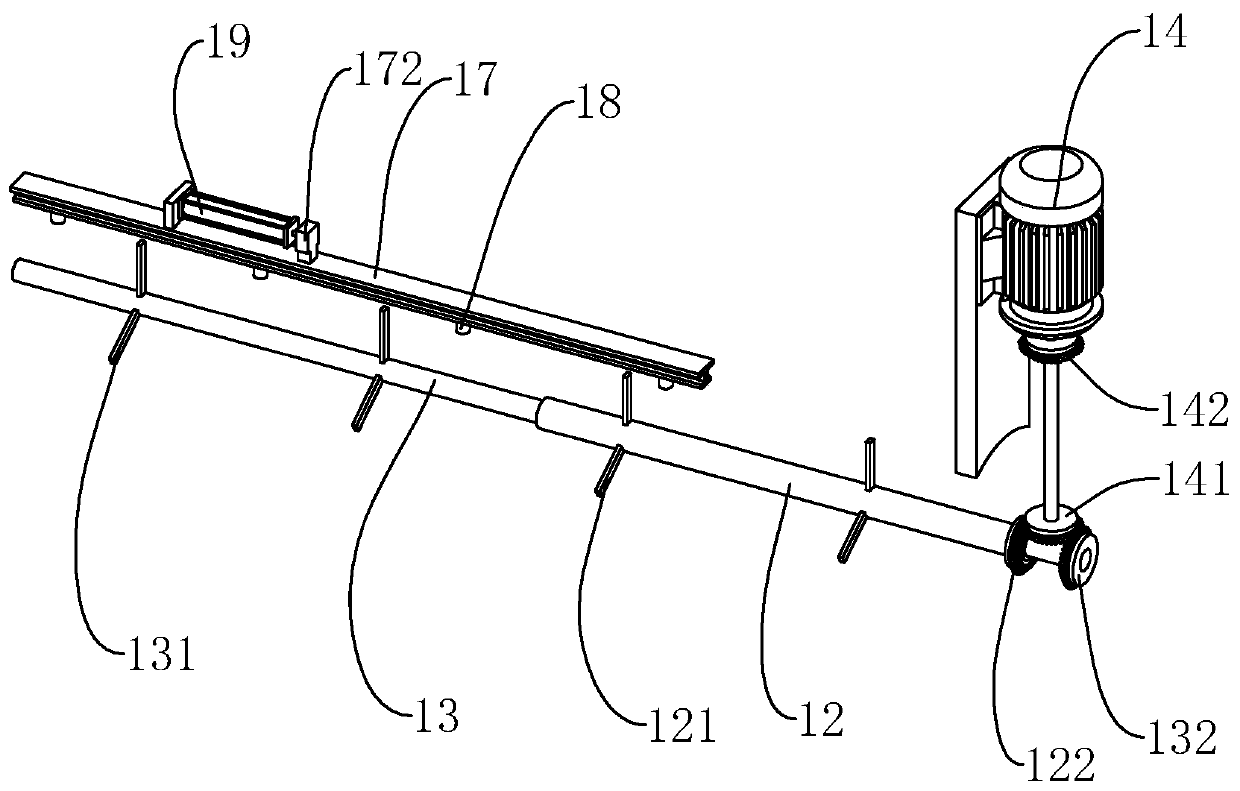

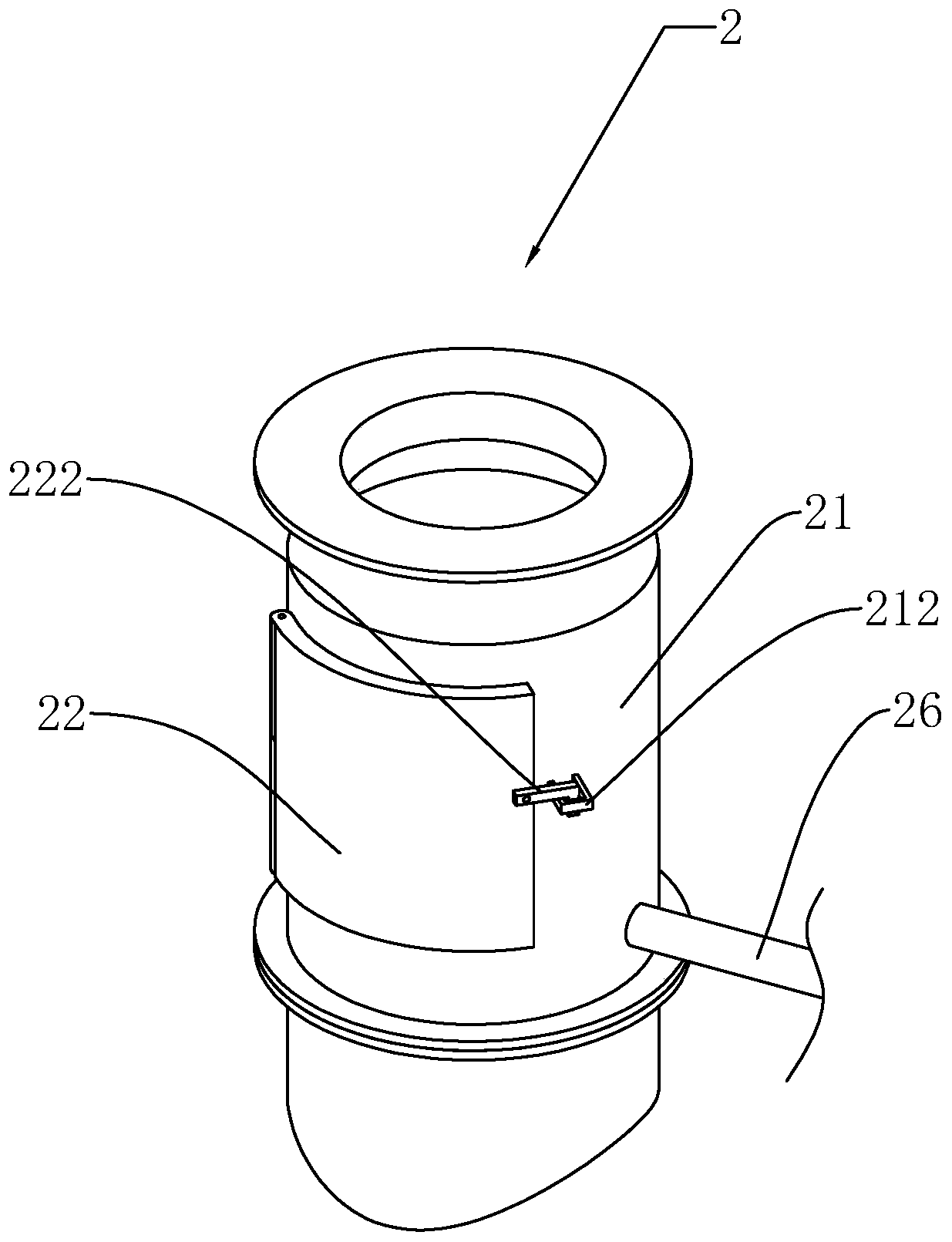

[0047] refer to figure 1 , the invention discloses a wheat flour processing production line, comprising a specific gravity destoner, a vibrating cleaning sieve, a permanent magnet cylinder 2, a watering machine 1, a plane rotary sieve, a flour mill, a flour cleaner, a square sieve, a mixer and Packing scale, the wheat passes through the specific gravity destoner, vibrating cleaning screen, permanent magnet cylinder 2, water machine 1, specific gravity destoner, plane rotary sieve, permanent magnet cylinder 2, flour mill, powder cleaner, high square sieve , mixer and packing scale to complete the processing process of wheat flour. Specific gravity destoner, vibrating cleaning sieve, plane rotary sieve, pulverizer, powder cleaning machine, square sieve, mixer and packing scale are all prior art, and are not described in detail here.

[0048] refer to figure 1 with figure 2 , the sprinkler 1 includes a body 11, the inside of the body 11 is a horizontal cylindrical hollow stru...

Embodiment 2

[0060] refer to figure 1 with Figure 5 , a process flow of a wheat flour processing production line, comprising the steps of:

[0061] S1 The operator first checks and accepts the wheat, selects clean, pollution-free, and mildew-free wheat, common wheat bulk density ≥ 750g / ml, high-gluten wheat bulk density ≥ 770g / ml, moisture < 12.5%, imperfect grains < 6%;

[0062] S2 processes the accepted wheat as fluff, so that the wheat passes through the specific gravity destoner, vibrating cleaning screen and permanent magnetic cylinder 2 in order to remove impurities such as sand, straw, dust, and metal objects in the wheat, and the removal rate of impurities reaches 99.9%. , impurity <0.1%;

[0063] S3 performs the wheat conditioning treatment on the wheat after the fluffy wheat treatment, using the water machine 1, the computer automatically moistens the wheat, and the wheat conditioning time is 30h-70h;

[0064] S4 cleans the wheat after tempering, so that the wheat passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com