A kind of plasticizer composite, preparation method and PVC composite material containing the same

A plasticizer and composite technology, applied in the field of plasticizer composites, preparation methods and PVC composite materials containing it, to achieve the effects of reducing color depth, reducing emissions, and reducing taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

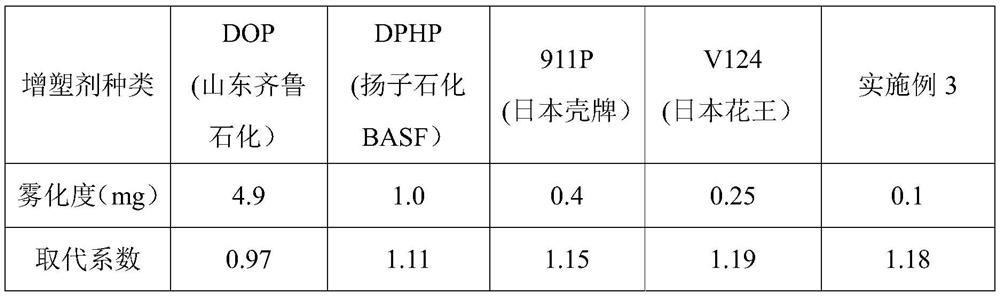

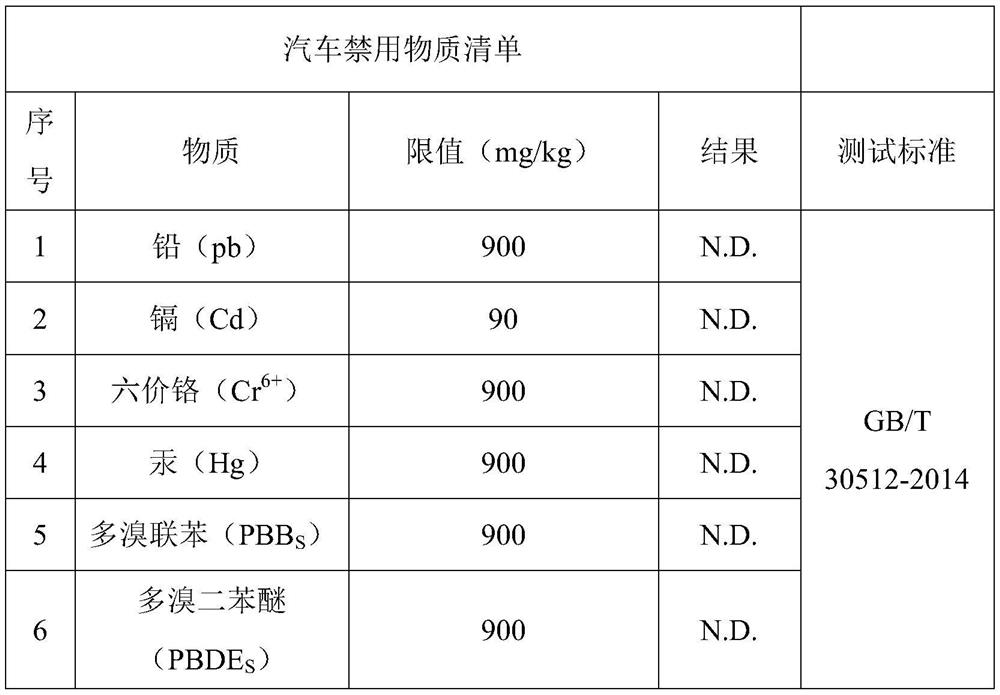

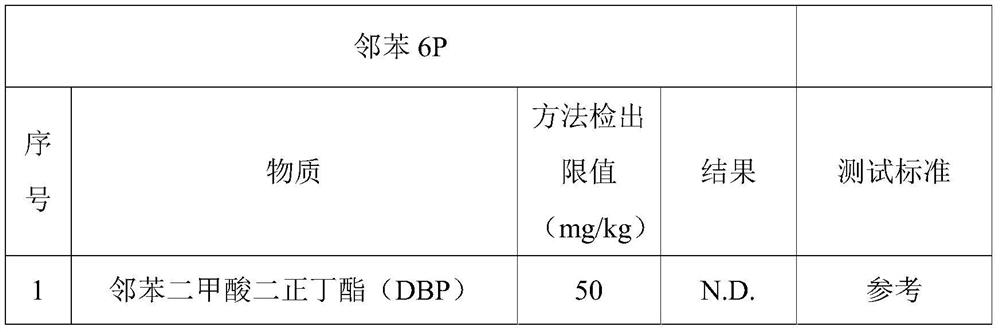

Examples

preparation example Construction

[0040] The second aspect of the present invention provides a preparation method of the plasticizer compound, which includes four steps of esterification reaction, refining, pressure filtration and molecular distillation.

[0041] Preferably, the preparation method of the plasticizer compound comprises the following steps:

[0042] (1) Esterification: add alcohol substances and dianhydride substances in the reaction kettle, then add a catalyst, when the temperature rises to 220±10 ° C, start to draw air into the reaction kettle, and make the kettle into a negative pressure state , when the acid value of esterification is less than or equal to 0.1mgKOH / g, continue to turn on the negative pressure of the vacuum pump and dealcohol;

[0043] (2) Refining: the substance in step (1) is cooled and added to alkaline water for neutralization, and after neutralization, the temperature is raised while stripping, and the temperature is raised to 215±10° C. to maintain the stripping for 2.5...

Embodiment 1

[0056] Embodiment 1 of the present invention provides a plasticizer, and the preparation raw materials are dianhydrides, alcohols, catalysts, alkaline water and filter aids;

[0057] Alcohols are dodecanol, n-decanol, isodecanol, n-decanol was purchased from Fengyi Alcohol Industrial Co., Ltd., carbonyl value is 1.9mg / kg; the weight ratio of dodecanol, n-decanol, isodecanol It is 1:1.4:1.2; dianhydrides are phthalic anhydrides with a purity greater than or equal to 99.5%; the weight ratio of alcohols to dianhydrides is 3.5:1;

[0058] The catalyst content is 0.7wt‰ of alcohols; the catalyst is isopropyl titanate;

[0059] The amount of alkaline water is 4wt‰ of the alcohol content; the alkaline water is 10wt% sodium carbonate aqueous solution;

[0060] The filter aid is diatomite, which is SZ-308; the content of the filter aid is 1‰ of the alcohol content;

[0061] The preparation method of the plasticizer compound comprises the following steps:

[0062] (1) Esterification ...

Embodiment 2

[0067] Embodiment 2 of the present invention provides a plasticizer, and the preparation raw materials are dianhydrides, alcohols, catalysts, alkaline water and filter aids;

[0068] Alcohols are dodecanol, n-decanol, isodecanol, n-decanol was purchased from Fengyi Alcohol Industrial Co., Ltd., carbonyl value is 1.9mg / kg; the weight ratio of dodecanol, n-decanol, isodecanol It is 1:1.2:0.8; the dianhydrides are phthalic anhydrides with a purity greater than or equal to 99.5%; the weight ratio of alcohols to dianhydrides is 2.5:1;

[0069] The catalyst content is 0.3wt‰ of alcohols; the catalyst is isopropyl titanate;

[0070] The amount of alkaline water is 2wt‰ of the alcohol content; the alkaline water is 10wt% sodium carbonate aqueous solution;

[0071] The filter aid is diatomite, which is SZ-308; the content of the filter aid is 0.3‰ of the alcohol content;

[0072] The preparation method of the plasticizer compound is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com