Fluorescent whitening agent for textile printing and dyeing

A fluorescent whitening agent, textile printing and dyeing technology, applied in the field of fluorescent whitening agent, can solve the problems of large amount of organic solvent, low yield, dark color of crude products, etc., and achieve the effect of improving product yield, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

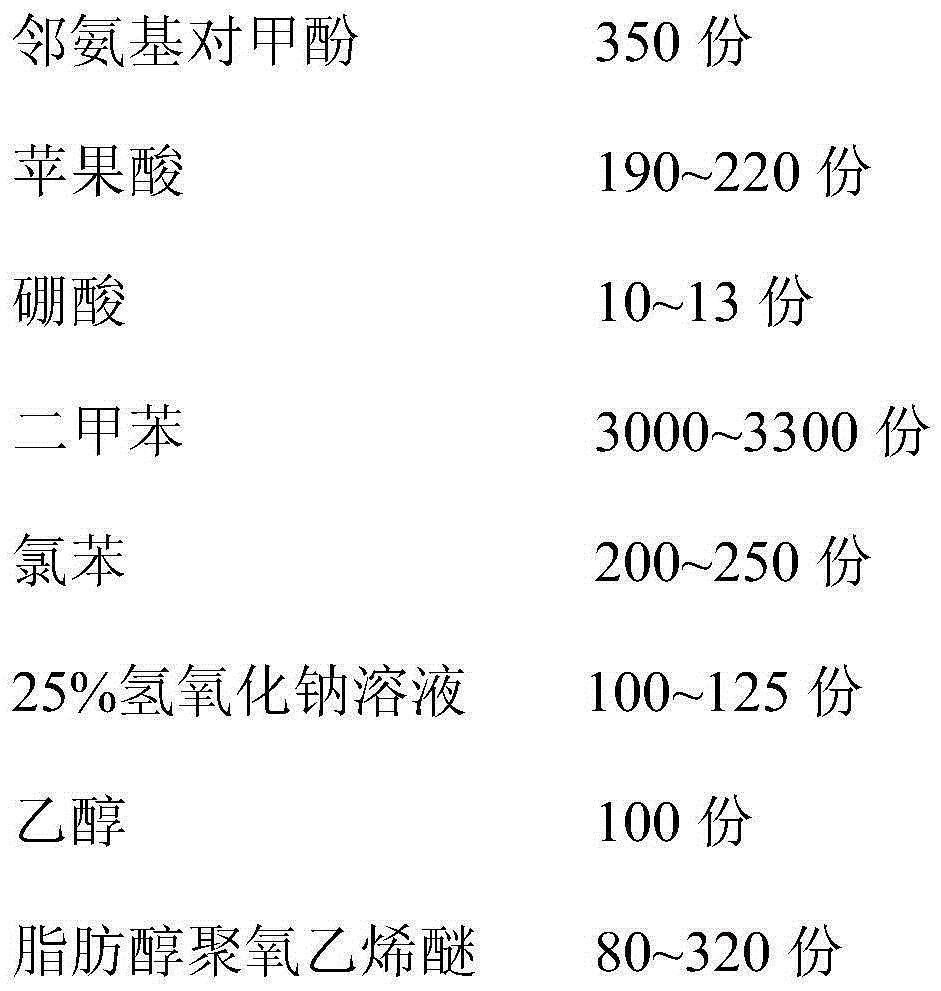

[0020] The proportioning of raw materials and reagents by weight is as follows:

[0021]

[0022] Concrete preparation process is as follows:

[0023] ①In the reaction kettle with agitator, reflux condenser and water separator, first add xylene, then add o-amino-p-cresol, malic acid and boric acid. Nitrogen was fed into the reaction kettle to protect the material, and the temperature of the reactant was raised to 40°C under constant stirring, and kept for 3 hours, and then within 2 hours, the temperature was raised to 145°C, and kept for 8 hours. Toluene is recovered through condensation and phase separation;

[0024] ②Under stirring conditions, when the temperature is lowered to 90°C, steam is passed through for distillation to drive out the remaining xylene;

[0025] ③ Add chlorobenzene, cool the reactant to 540°C, and keep stirring to dissolve all the materials in the reactor;

[0026] ④ Add sodium chloride solution and ethanol polyoxyethylene ether, heat up to 80°C u...

Embodiment 2

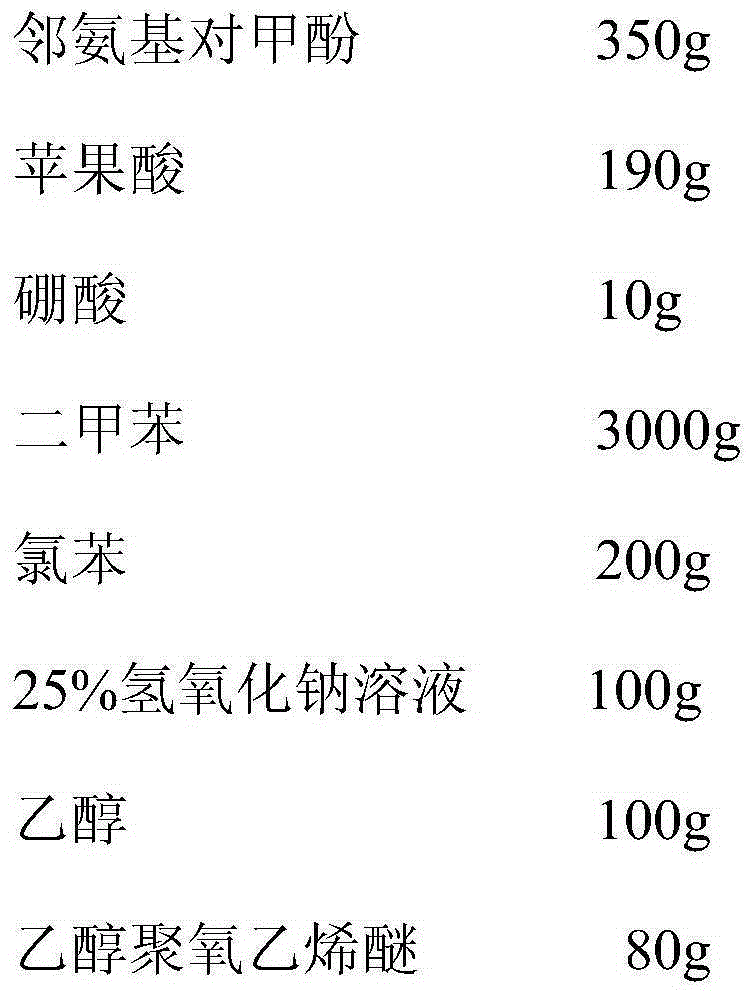

[0031] The proportioning of raw materials and reagents by weight is as follows:

[0032]

[0033] Concrete preparation process is with specific embodiment 1.

Embodiment 3

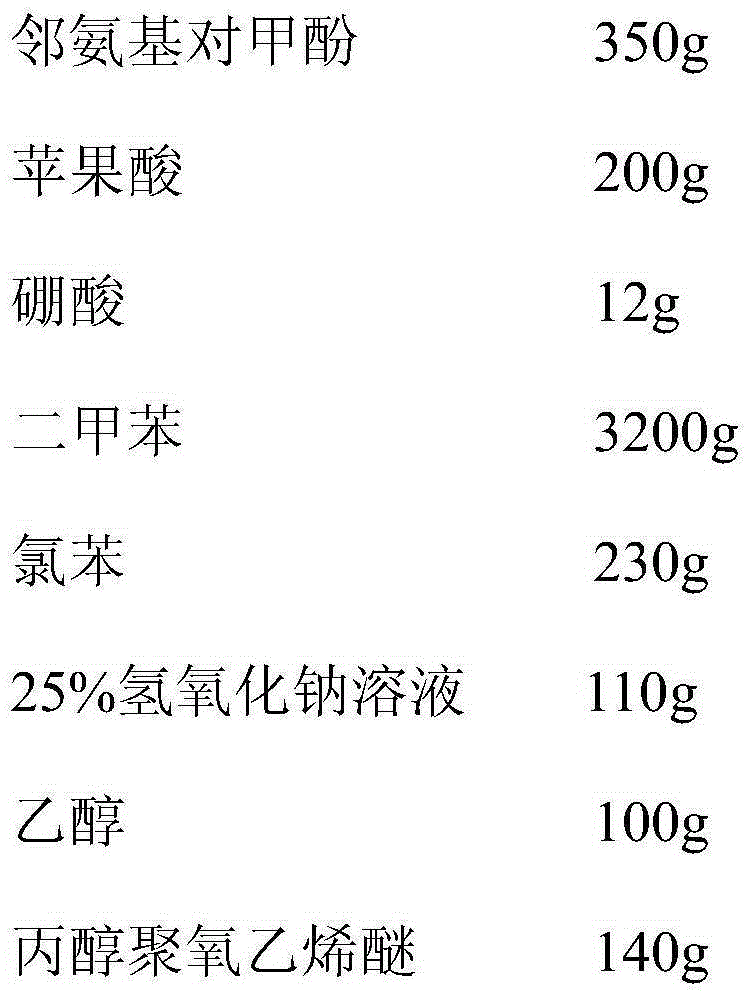

[0035] The proportioning of raw materials and reagents by weight is as follows:

[0036]

[0037] Concrete preparation process is with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com