Radioactive foam detergent and preparation method thereof

A detergent and radioactive technology, applied in chemical instruments and methods, surface active detergent compositions, detergent compositions, etc., to achieve the effects of strong complexing ability and good environmental compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

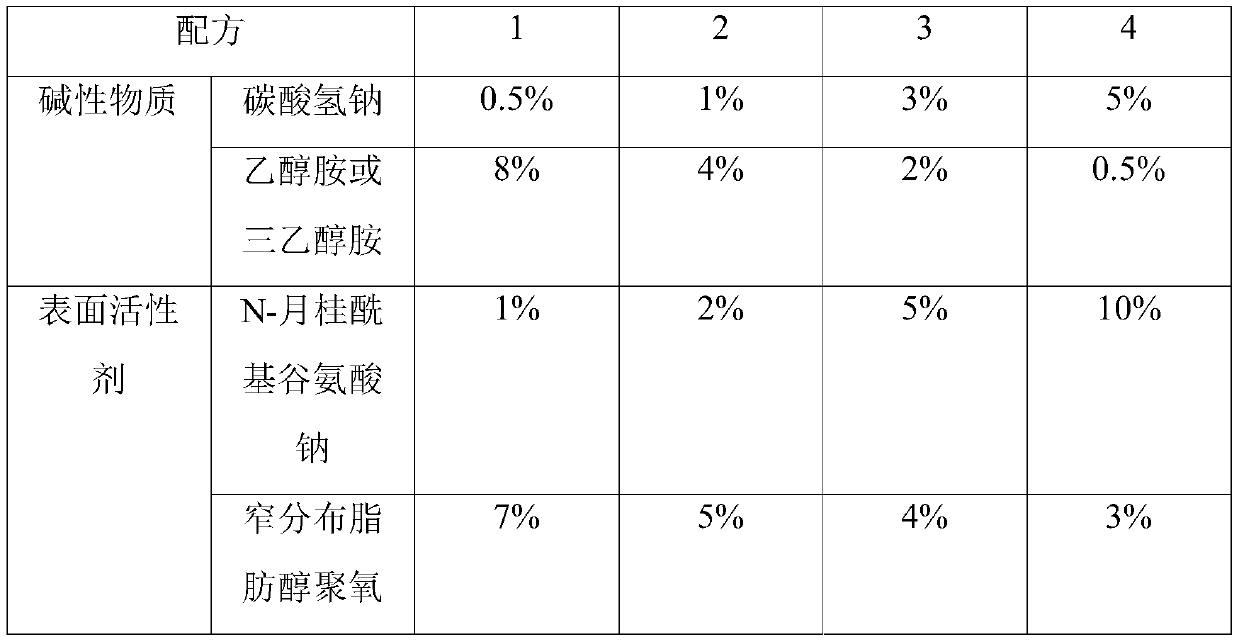

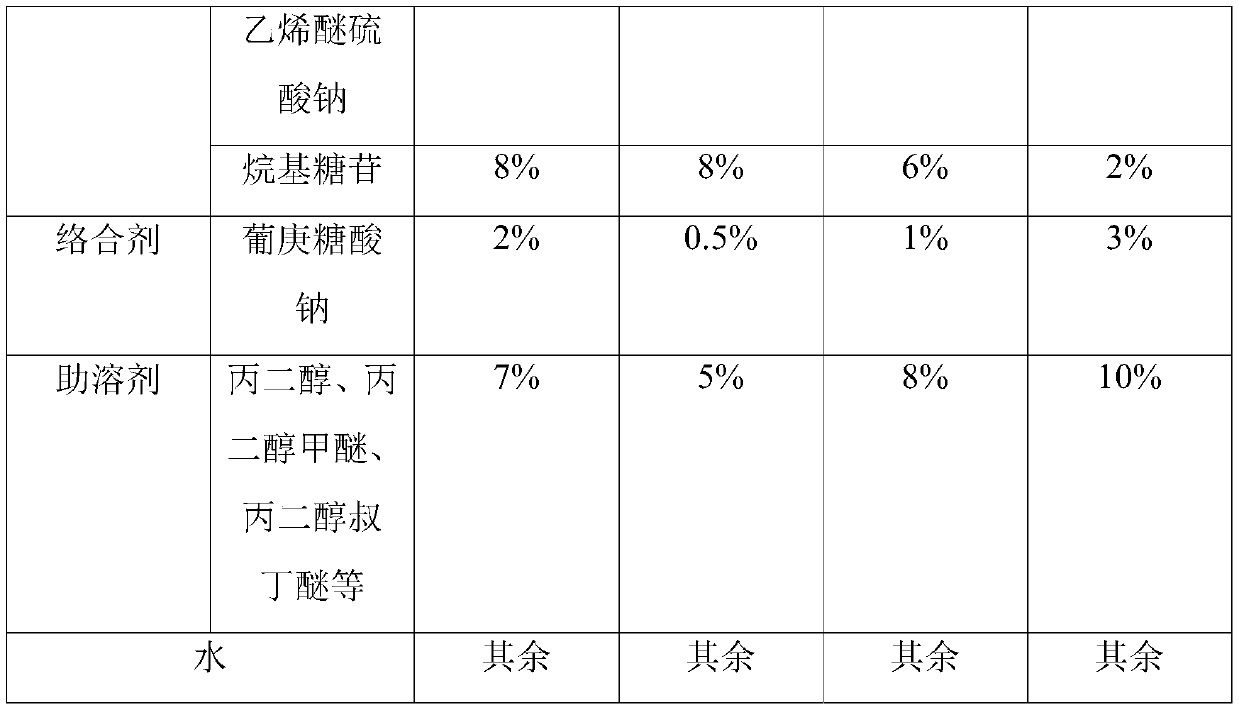

Embodiment 1

[0019] A radioactive foam detergent prepared from the following raw materials: sodium bicarbonate 0.5%, ethanolamine 8%, sodium N-lauroyl glutamate 1%, narrowly distributed fatty alcohol polyoxyethylene ether sodium sulfate 7%, alkanes 8% glucoside, 0.5-3% sodium glucoheptonate, 7% propylene glycol, and the balance is water.

[0020] The preparation method is as follows: firstly weigh the amount of water in the formula, add sodium bicarbonate, dissolve, and stir evenly; then add ethanolamine, sodium glucoheptonate, propylene glycol, stir to dissolve completely, and finally add N-lauroyl glutamic acid 1% of sodium, 7% of narrowly distributed fatty alcohol polyoxyethylene ether sodium sulfate, and 8% of alkyl glycosides are used to obtain a finished radioactive foam detergent.

Embodiment 2

[0022] A radioactive foam detergent prepared from the following raw materials: 1% sodium bicarbonate, 4% triethanolamine, 2% sodium N-lauroyl glutamate, 5% sodium sulfate of narrowly distributed fatty alcohol polyoxyethylene ether, Alkyl glucoside 8%, sodium glucoheptonate 0.5%, propylene glycol methyl ether 5%, and the balance is water.

[0023] Its preparation method is with embodiment 1.

Embodiment 3

[0025] A radioactive foam detergent prepared from the following raw materials: 3% sodium bicarbonate, 2% ethanolamine, 2% sodium epi-N-lauroyl glutamate, 5% narrowly distributed fatty alcohol polyoxyethylene ether sodium sulfate, Alkyl glucoside 8%, sodium glucoheptonate 1%, propylene glycol tert-butyl ether 8%, and the balance is water.

[0026] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com