Nitriding agent for oxynitrocarburizing technology and preparation method thereof

A technology of nitriding agent, nitrogen, carbon and oxygen, which is applied in the field of nitriding agent and its preparation of nitrocarburizing technology, which can solve the problems of poor fluidity and stability, high density of nitriding agent, low yield of finished products, etc. problems, to achieve the effect of stable quality, low production cost and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

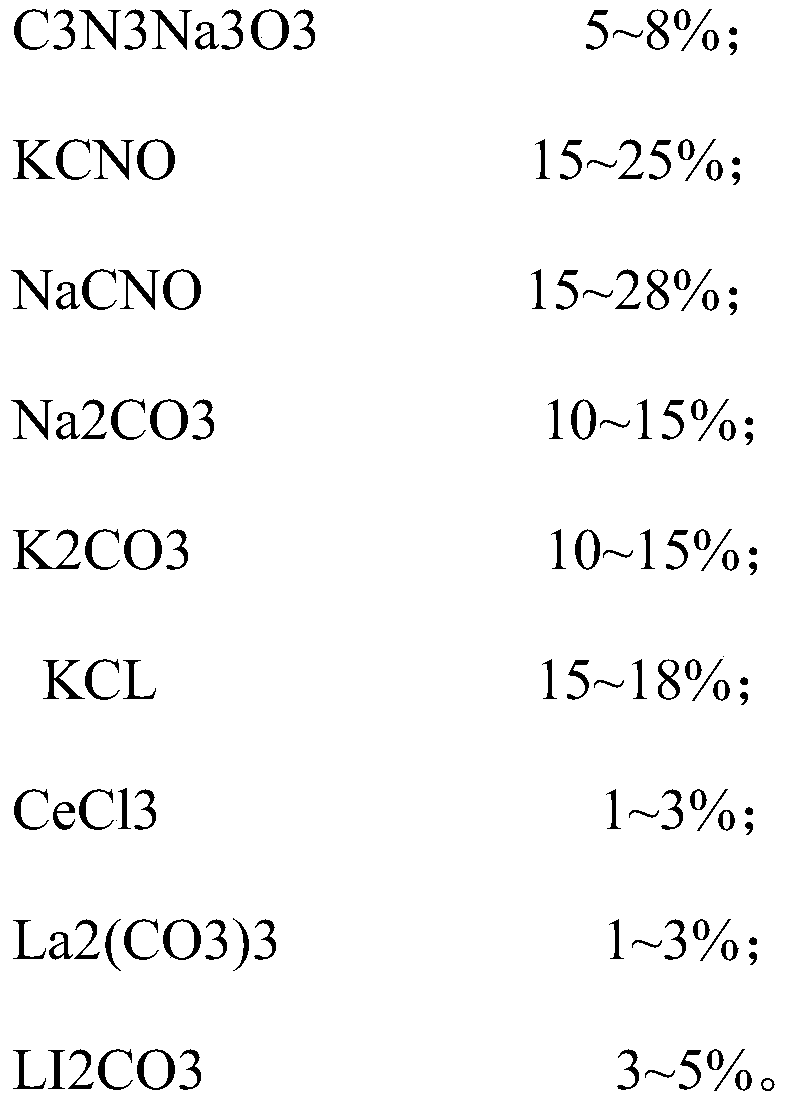

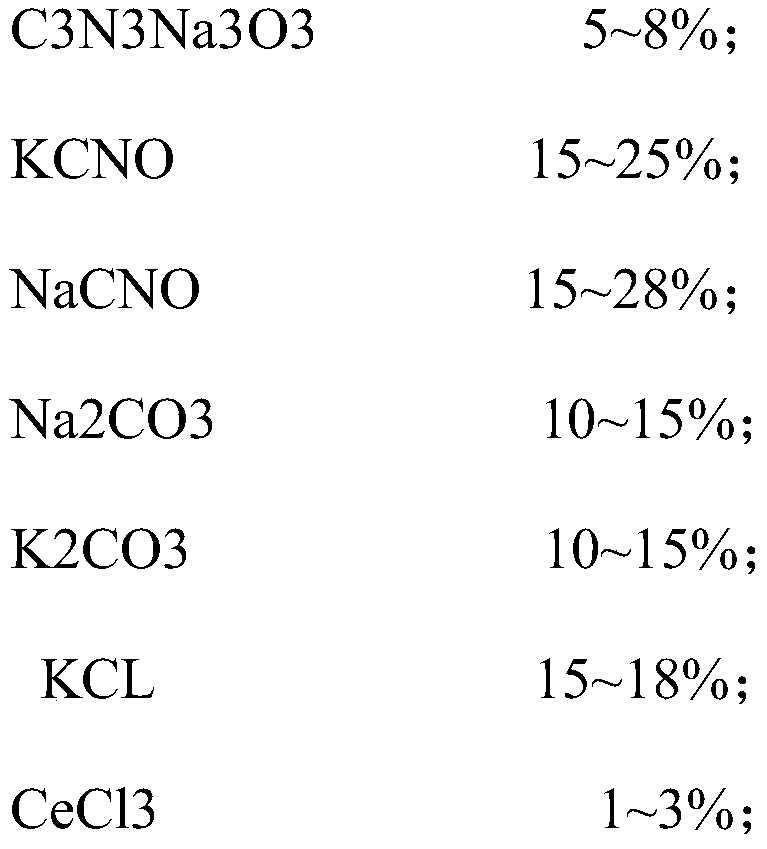

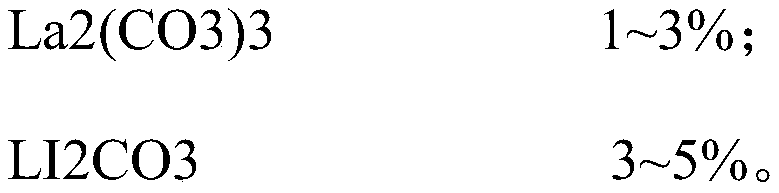

[0035] A nitriding agent for nitrocarburizing technology and a preparation method thereof, comprising the following mass fractions:

[0036]

[0037] The present invention is by adding lanthanum cerium rare earth element, and lanthanum cerium rare earth is used as catalyst, can improve seepage velocity, conventional knowledge all understands that rare earth has the effect of urging infiltration in surface treatment industry, but adding ratio has unique peak value according to nitriding agent formula.

[0038] The present invention has the effect of anti-high temperature stability to the whole nitriding agent by adding a small amount of lithium carbonate, so it is also necessary to form the melting intermediate of the nitriding agent, so as to reduce the shortage of raw materials and the waste of cost.

[0039] In this example, Na+:K+=1:1.1 in the nitriding agent. According to the theory of fusion eutectic design, the ratio of Na+:K+ is 1:1.1, and the eutectic composition for...

Embodiment 1

[0055]

[0056] Smelting and refining steps:

[0057] Step 1: Divide the penetrating agent into:

[0058] Penetration agent base agent (sodium cyanurate, sodium cyanate, potassium cyanate, potassium carbonate, sodium carbonate, potassium chloride) accounted for 91%;

[0059] Penetrating agent melting intermediates (lithium carbonate, potassium aluminum sulfate, cerium chloride, lanthanum carbonate) account for 9%;

[0060] Step 2: Prepare the media material cyanuric acid as the weight ratio of 5% of the penetrating agent

[0061] Step 3: Melt the penetrating agent into the intermediate, then add the medium material cyanuric acid, melt and keep it at 520-550°C for 4 hours, and cool it into a block;

[0062] Step 4: Heat the penetrating agent base agent at 580-620°C for 4 hours, then add the penetrating agent to melt the intermediate, and keep warm for 2 hours;

[0063] Step 5: Cool into blocks and pack according to the specified weight.

[0064]

Embodiment 2

[0066]

[0067] Smelting and refining steps:

[0068] Step 1: Divide the penetrating agent into:

[0069] Penetration agent base agent (sodium cyanurate, sodium cyanate, potassium cyanate, potassium carbonate, sodium carbonate, potassium chloride) accounted for 92%;

[0070] Penetration agent melting intermediate (lithium carbonate, potassium aluminum sulfate, cerium chloride, lanthanum carbonate) accounted for 8%;

[0071] Step 2: The medium material cyanuric acid is 20% by weight of the penetrating agent;

[0072] Step 3: Melt the penetrating agent into the intermediate, then add the medium material cyanuric acid, melt and keep it at 520-550°C for 4 hours, and cool it into a block;

[0073] Step 4: Heat the penetrating agent base agent at 580-620°C for 4 hours, then add the penetrating agent to melt the intermediate, and keep warm for 2 hours;

[0074] Step 5: Cool into blocks and pack according to the specified weight.

[0075]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com