Modified ES fiber containing tea polyphenol, naringin or rheum emodin and preparing method of modified ES fiber

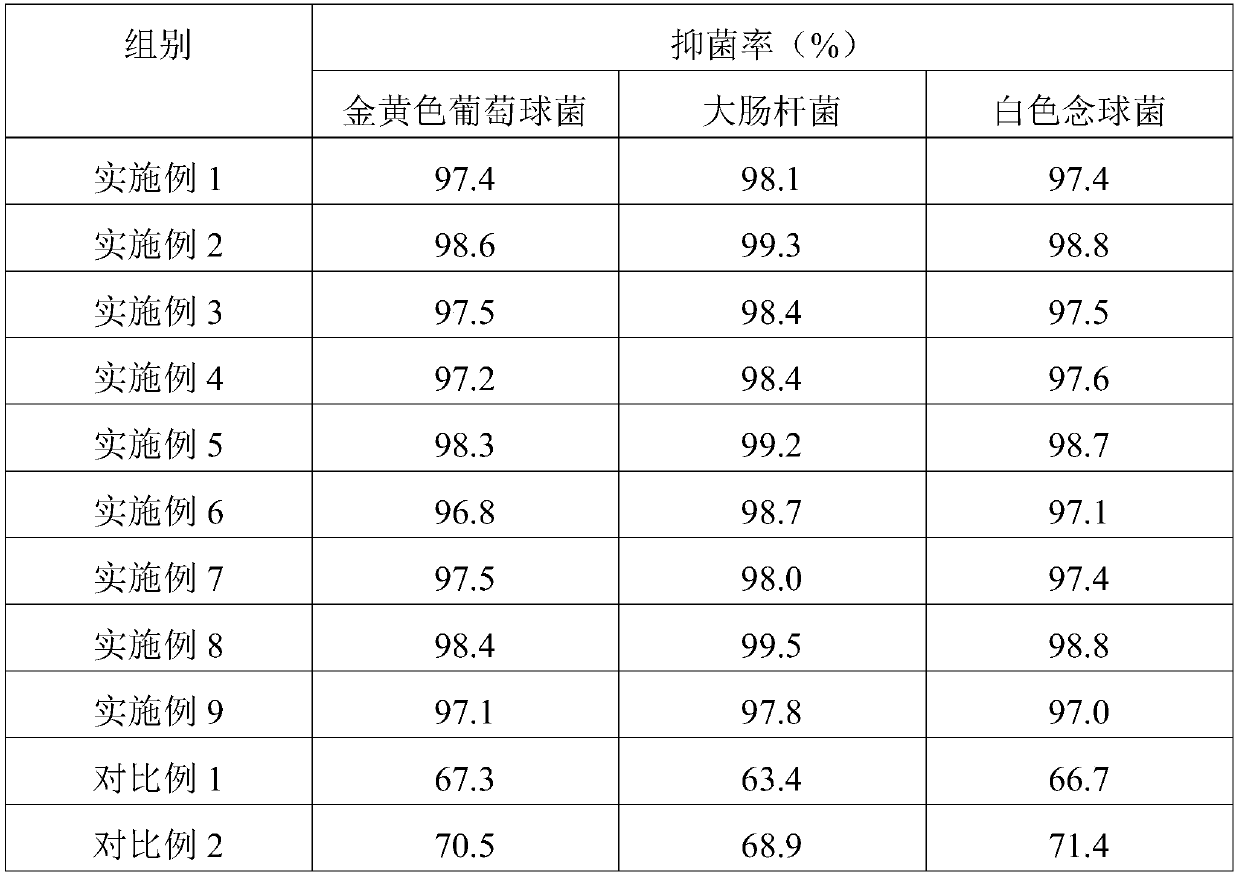

A technology of naringin and emodin, applied in the field of spinning, can solve the problems of poor antibacterial performance, mechanical performance and hygroscopicity, and achieve the effect of increasing antibacterial performance, increasing uniformity and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of tea polyphenol modified ES fiber of this embodiment, the mass percentage of tea polyphenol is 0.1%, described tea polyphenol undergoes the following modification treatment: add tea polyphenol into water and stir until completely dissolved, described The mass ratio of tea polyphenols to water is 1:5, adding porous nano-TiO 2 Microspheres, tea polyphenols and porous nano-TiO 2 The mass ratio of the microspheres is 1:5, stirring, the stirring speed is 30r / min, and the stirring time is 120min, to obtain a modified nanocomposite material.

[0029] The preparation method of the tea polyphenol modified ES fiber of the present embodiment comprises the steps:

[0030] (1) Preparation of functional masterbatch: Add 92kg of PE chips, 0.2kg of phosphite amine, 0.2kg of zinc stearate and 4kg of modified nanocomposite into the twin-screw extruder, mix and granulate , to obtain the functional masterbatch;

[0031] (2) Preparation of modified ES fibers: PP slices and the f...

Embodiment 2

[0033] A kind of tea polyphenol modified ES fiber of this embodiment, the mass percentage of tea polyphenol is 2.5%, described tea polyphenol undergoes the following modification treatment: add tea polyphenol into water and stir until completely dissolved, described The mass ratio of tea polyphenols to water is 1:7.5, adding porous nano-SiO 2 Microspheres, tea polyphenols and porous nano-SiO 2 The mass ratio of the microspheres is 1:7.5, stirring, the stirring speed is 45r / min, and the stirring time is 75min, to obtain a modified nanocomposite material.

[0034] The preparation method of the tea polyphenol modified ES fiber of the present embodiment comprises the steps:

[0035] (1) Preparation of functional masterbatch: sequentially add 93kg of PE chips, 0.3kg of phosphite amine, 0.35kg of calcium stearate and 6kg of modified nanocomposite into the twin-screw extruder, mix and granulate , to obtain the functional masterbatch;

[0036] (2) Preparation of modified ES fibers:...

Embodiment 3

[0038] A kind of tea polyphenol modified ES fiber of this embodiment, the mass percentage of tea polyphenol is 5%, described tea polyphenol undergoes the following modification treatment: add tea polyphenol into water and stir until completely dissolved, described The mass ratio of tea polyphenols to water is 1:10, adding montmorillonite and porous nano-SiO 2 Microspheres, tea polyphenols with montmorillonite and porous nano-SiO 2 The total mass ratio of microspheres is 1:10, montmorillonite and porous nano-SiO 2 The mass ratio of the microspheres is 1:1, stirring, the stirring speed is 60r / min, and the stirring time is 30min, to obtain a modified nanocomposite material.

[0039] The preparation method of the tea polyphenol modified ES fiber of the present embodiment comprises the steps:

[0040] (1) Preparation of functional masterbatch: Add 94kg of PE slices, 0.4kg of phosphite amine, 0.5kg of stearic acid and 8kg of modified nanocomposite into the twin-screw extruder, mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com