Fluidized-bed boiler monitoring system based on PLC and configuration software

A monitoring system and configuration software technology, applied in the field of programmable controllers, can solve problems such as poor control of the speed of the coal feeder, flameout or coking of the boiling boiler, positive pressure in the furnace chamber, etc., to meet the needs of power generation production, Reduced energy consumption and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

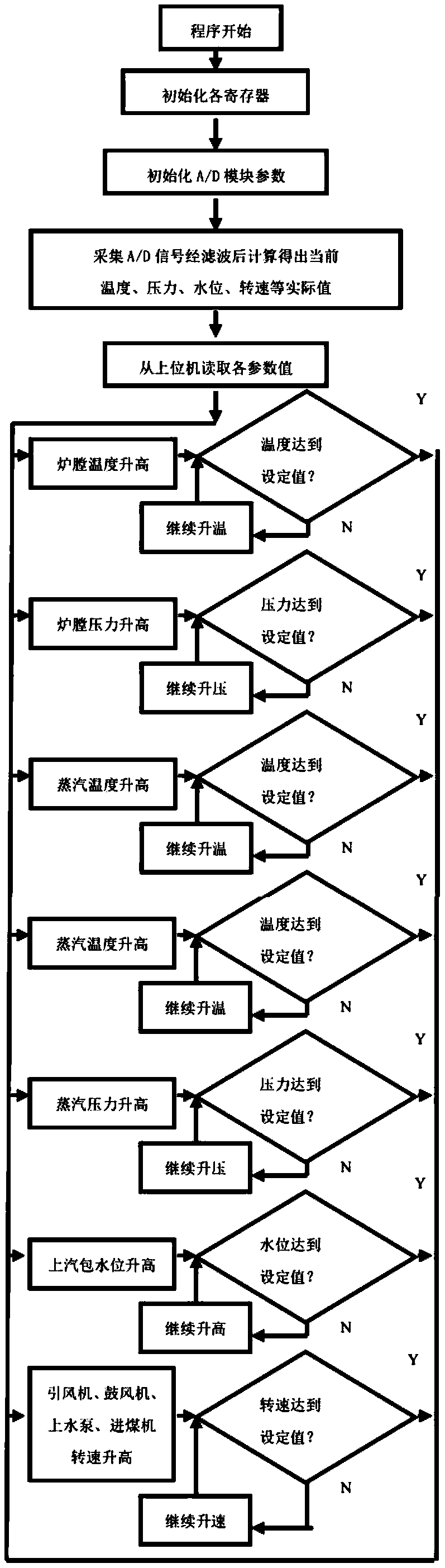

[0032] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

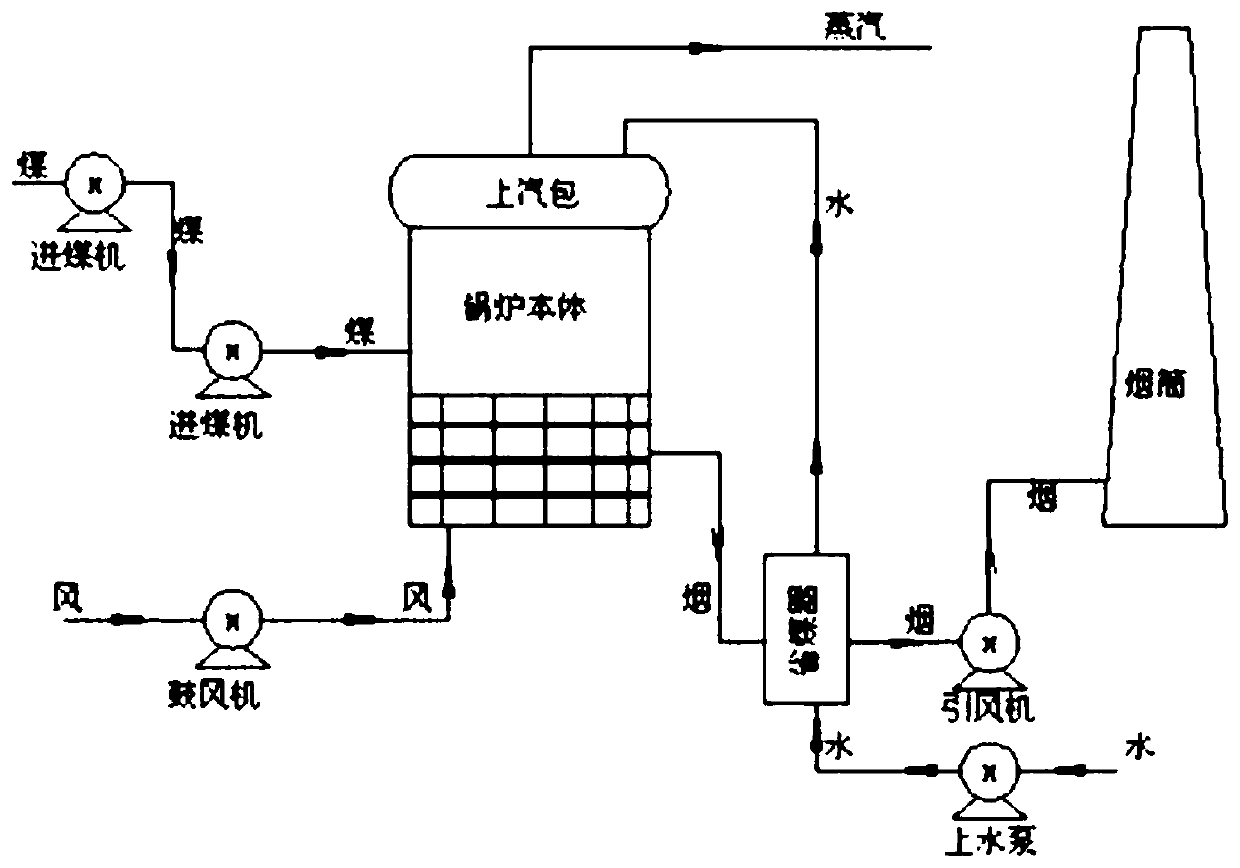

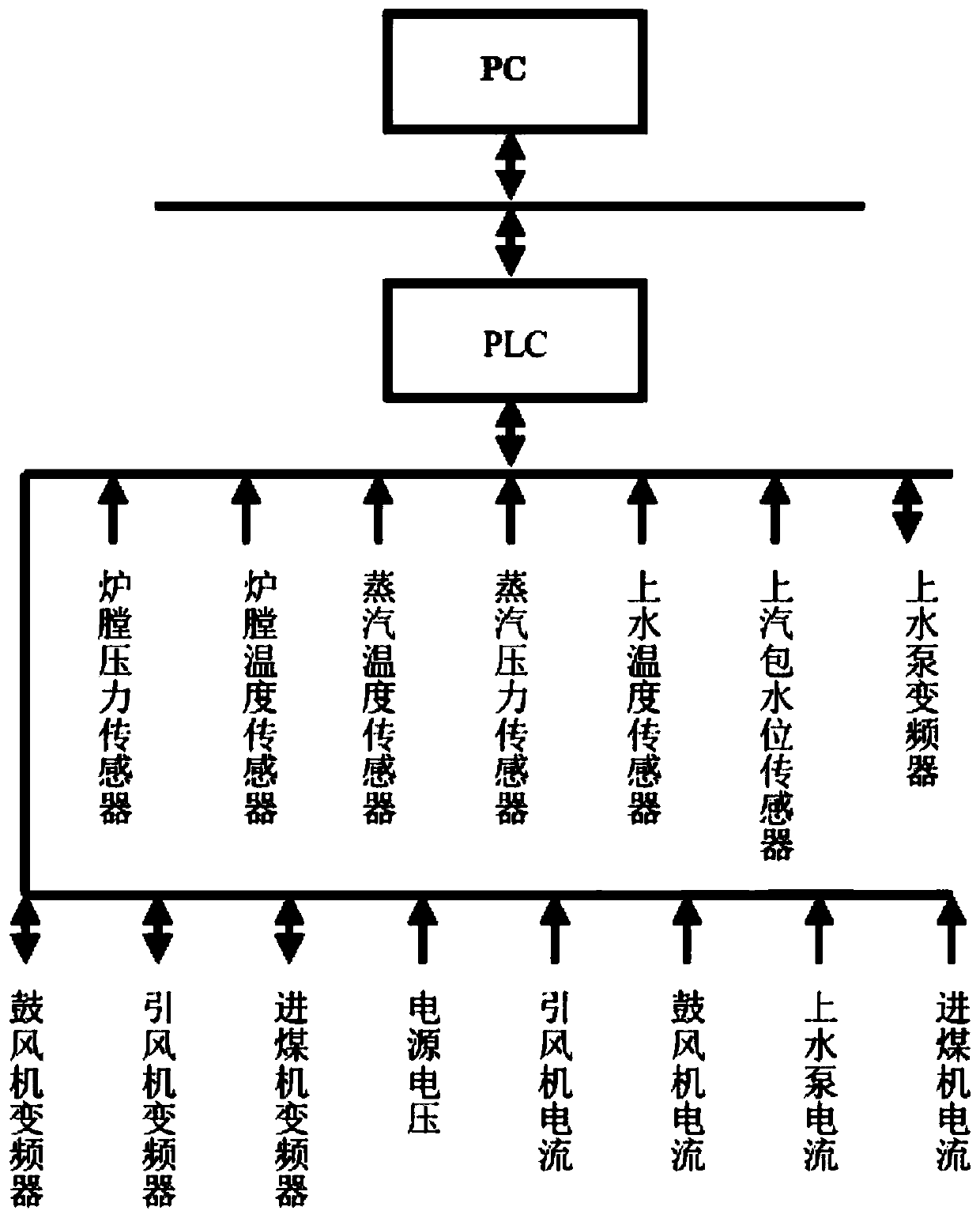

[0033] Such as Figure 2-4 As shown, a fluidized boiler monitoring system consists of an upper computer, a lower computer, a number of detection devices and a number of drive controllers; wherein, the upper computer is a PC, and the lower computer is a PLC.

[0034] Among them, several detection devices are sensor detection devices, including a furnace pressure sensor for detecting the furnace pressure, a furnace temperature sensor for detecting the furnace temperature, an upper drum water level sensor for detecting the water level of the upper steam drum, and an upper drum water level sensor for detecting the steam temperature. Water temperature sensor, steam pressure sensor for detecting steam pressure, steam temperature sensor for detecting steam temperature;

[0035] Several drive controllers include a blower frequency converter for detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com