10nm-level particle detection device and method applied to ballistic target test

A technology for detection devices and ballistic targets, which can be used in measuring devices, aerodynamic tests, fluid velocity measurements, etc. It can solve the problems that the test cost and cycle cannot meet the requirements, the detection of 10nm-level particles cannot be realized, and the uncertainty of detection results, etc. , to achieve accurate measurement of collision process parameters, reliable and accurate detection, and improved detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

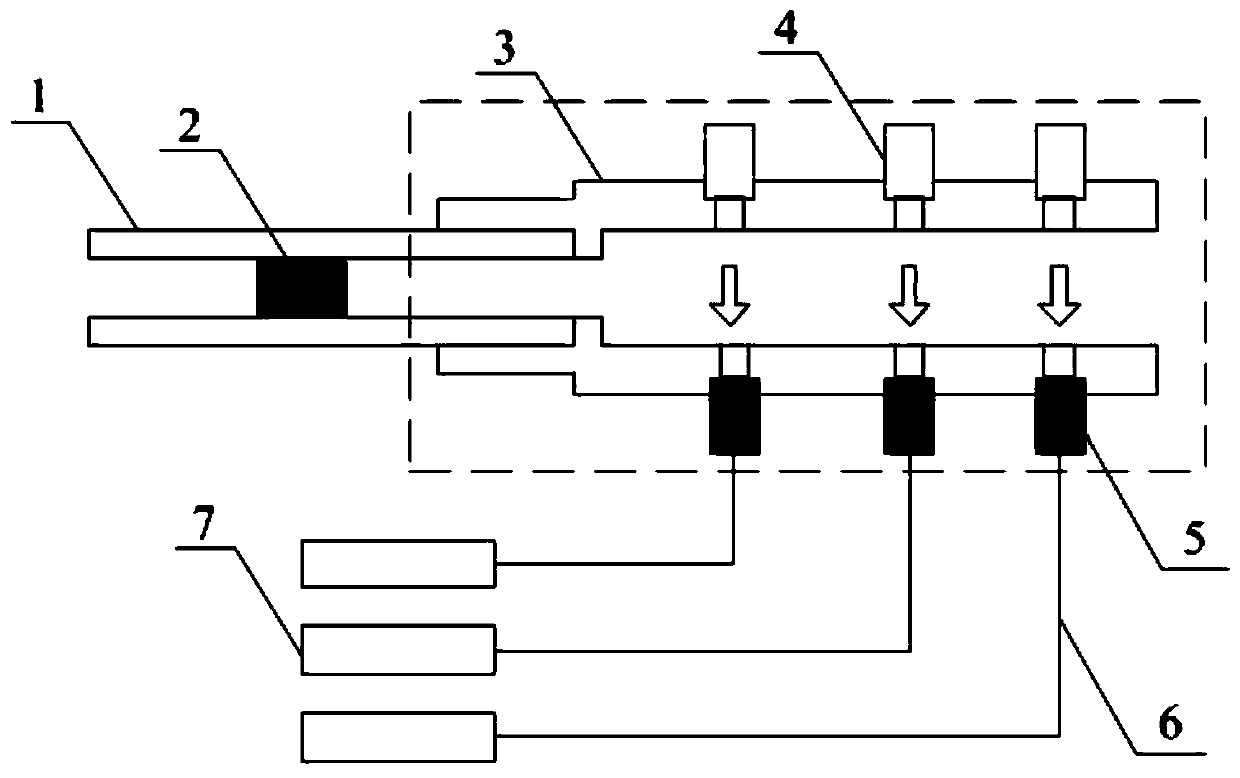

[0042] Such as figure 1 As shown, it is a 10nm particle detection device applied to a ballistic target test provided by Embodiment 1 of the present invention, and the 10nm particle detection device is arranged at the exit of the emitter 1 . The 10nm particle detection device of the present invention includes a fixture 3 , a laser 4 , a coupling lens 5 and a photodetector 7 .

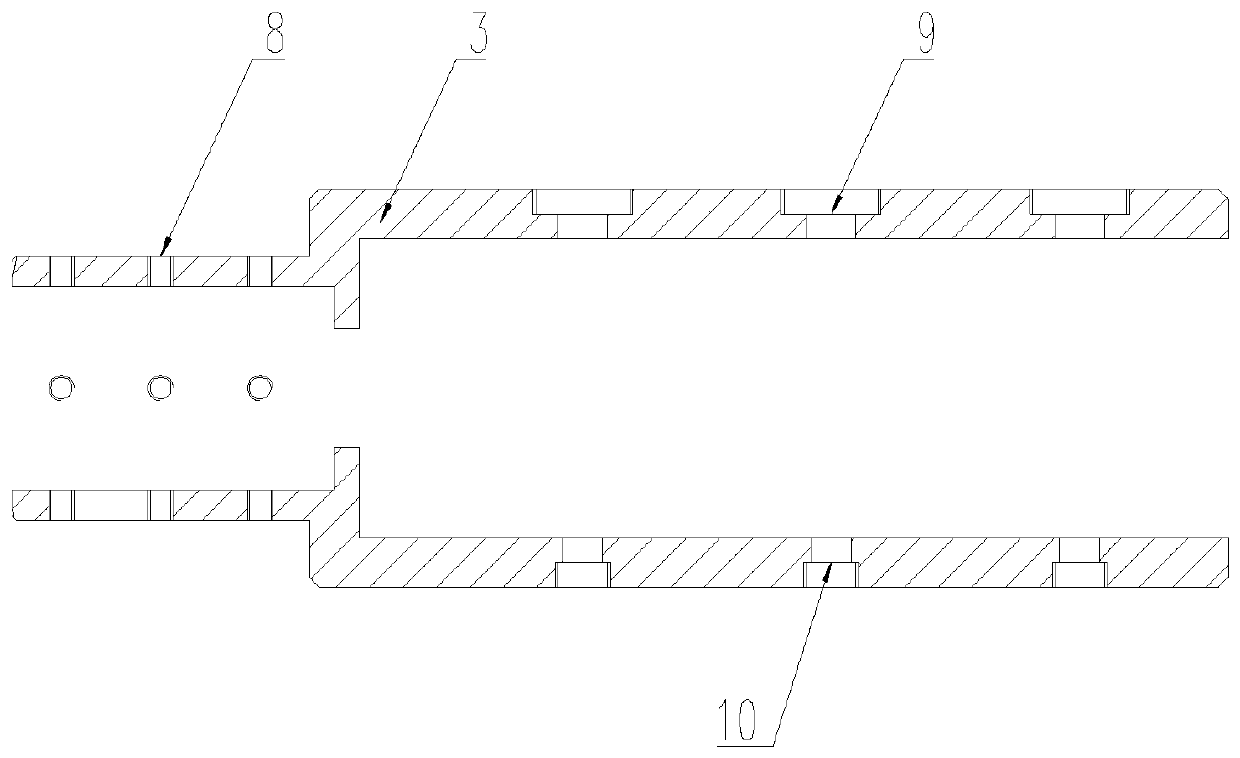

[0043] Among them, the clamp 3 is used to connect the transmitter 1 and provide a mounting base for the components of the device. Specifically, the clamp 3 includes a connection part and a mounting part, referring to figure 2As shown, the left part of the fixture 3 is a connecting part, which has an axial through hole, and the right part of the fixture 3 is a mounting part, which includes a first mounting plate and a second mounting plate, the first mounting plate and the second mounting plate The two mounting plates are arranged in parallel and at intervals to form a light curtain cavity with an open...

Embodiment 2

[0058] Embodiment 2 is basically the same as Embodiment 1, and the similarities will not be described in detail. The difference lies in:

[0059] The device includes a plurality of lasers 4, and the plurality of lasers 4 are arranged at intervals in parallel with the axial direction of the axial through hole. For example, two lasers 4 may be provided for particle velocity measurement, and the corresponding number of coupling lenses 5 and photodetectors 7 is also two. It should be understood that when used for particle velocity measurement, a timer should also be provided according to the test requirements. In the present invention, the numbers of the above-mentioned lasers 4 , coupling lenses 5 and photodetectors 7 can be appropriately increased or decreased. The specific quantity can be set according to the test requirements. When there are multiple lasers 4, coupling lenses 5 and photodetectors 7, the device can realize experiments and researches such as 10nm-level particl...

Embodiment 3

[0061] Embodiment 3 of the present invention provides a 10nm-level particle detection method applied to ballistic target testing, including: providing a light curtain cavity communicated with the outlet channel of the transmitter 1, the light curtain cavity is located in the target chamber, and the two opposite sides of the light curtain cavity The side has an axial opening communicating with the target chamber;

[0062] Provide at least one laser 4, installed on one side of the light curtain cavity;

[0063] Provide the same number of coupling lenses 5 as the number of lasers 4, installed on the other side of the light curtain cavity;

[0064] Provide photodetector 7 with the same number as coupling lens 5, installed outside the target chamber, photodetector 7 is connected with coupling lens 5 through optical fiber 6;

[0065] Debug voltage acquisition equipment;

[0066] Set the parameters of the voltage acquisition device, including acquisition time, sampling rate and tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com