Catalytic electrode with phosphorus selectivity and preparation method thereof

A catalytic electrode and selectivity technology, which is applied in the field of catalytic electrode with phosphorus selectivity and its preparation, can solve the problem that no titanium-based ruthenium-based catalytic electrode material has been found, and achieve low-concentration phosphorus pollution-free degradation and high-efficiency degradation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

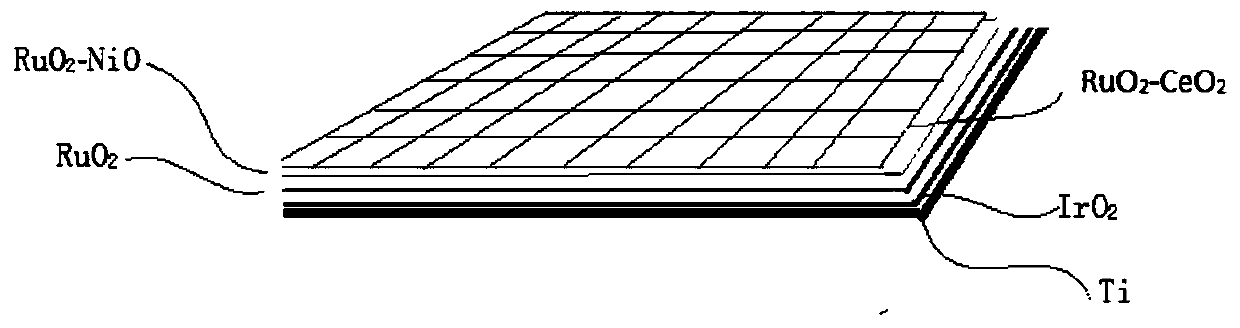

[0028] This embodiment provides a kind of catalytic electrode material with phosphorus selectivity, it is characterized in that, this electrode is to form IrO by Ti substrate outwards 2 -RuO 2 Multiple transitional gradient coatings, the outermost and second outermost layers are RuO 2 Coatings doped with Ce and Ni respectively;

[0029] The RuO 2 For catalytic activity, the IrO 2 For auxiliary conduction and catalysis. RuO 2 The thickness is 1-2μm, IrO 2 The thickness is 0.5-1μm; the outermost layer is RuO 2 -CeO 2 , the second outer layer is RuO 2 -NiO(Ni 2 o 3 ) network structure with a layer thickness of 1 μm.

[0030] This embodiment provides a method for preparing a catalytic electrode material with phosphorus selectivity, comprising the following steps:

[0031] Using Ti with a thickness of 2.0mm as the substrate, the surface is activated and modified with HF to form TiH 2 activated membrane,

[0032] Ruthenium trichloride (RuCl 3 ·3H 2 O) or ammonium chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com