Preparation method of activated carbon capable of selectively adsorbing palladium

An activated carbon and selective technology, which is applied in the field of palladium recovery from waste circuit boards, can solve problems such as weak coordination ability, product performance degradation, and loss of active ingredients, and achieve the effect of recyclability and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific implementation 1

[0024] 1. Activated carbon pretreatment: According to the process, take 350g of activated carbon, stir and wash with 1mol / L HCl solution for 1h, filter, and then wash with deionized water several times until the washing liquid is neutral. Finally, it is dried in a vacuum drying oven.

[0025] 2. Chlorination of activated carbon: Take 100g of pretreated activated carbon in a crucible and place it in a tube furnace. Close the furnace tube and vacuum, then open the nitrogen and chlorine valves, and keep the flow ratio of nitrogen to chlorine at 4. Set the heating rate to 50°C / h, the target temperature to 800°C, and the holding time for 12 hours.

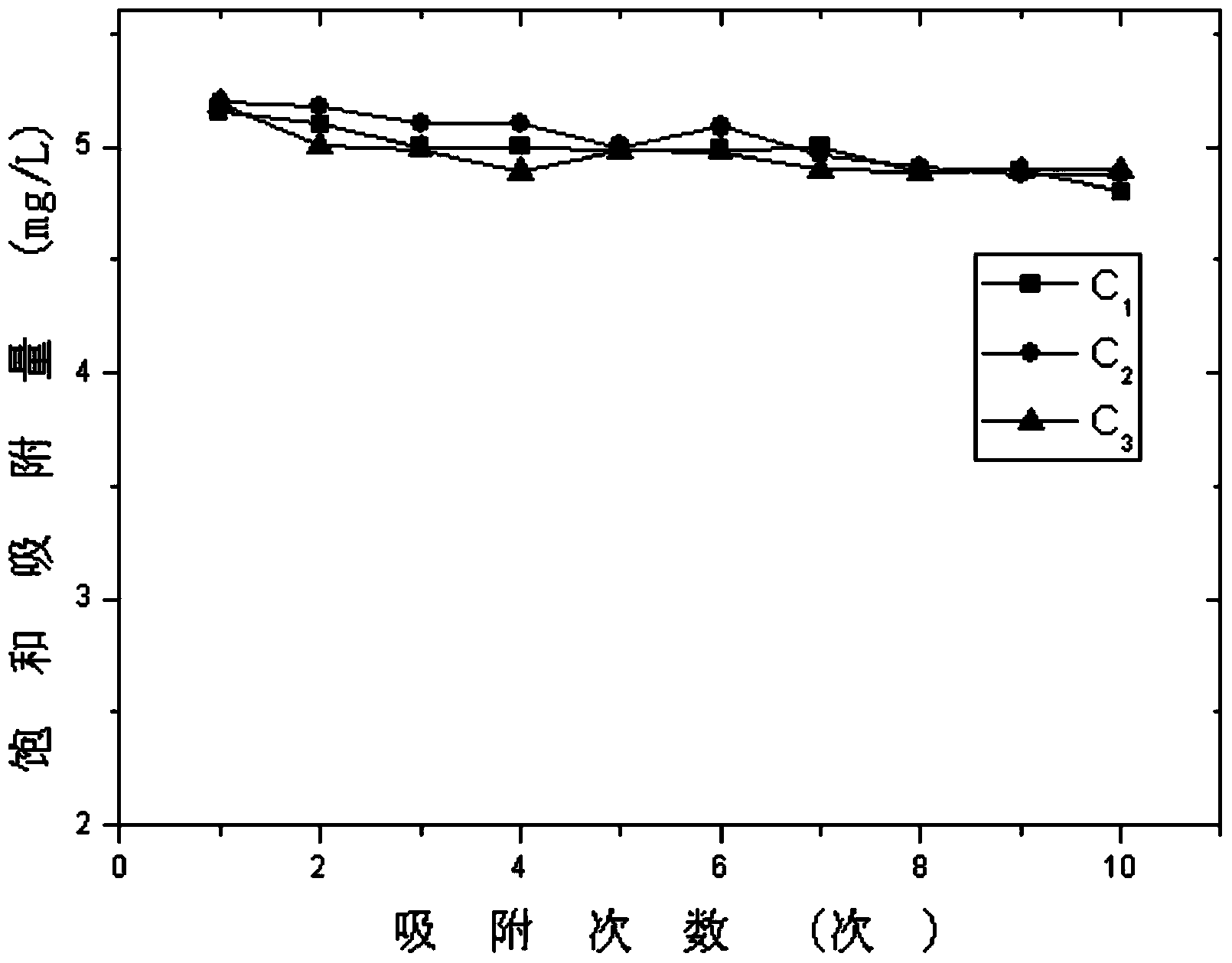

[0026] 3. Addition of sulfide functional group: take 0.025g Na 2 S was placed in the reaction flask, and 75% (volume percentage, the same below) 250 mL of ethanol was added. Subsequently, 50g of chlorinated activated carbon was added and heated to 75°C and kept for 6 hours. After the reaction, 48.987g of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com