Silver ion adsorption material as well as preparation method and application thereof

An adsorption material and silver ion technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of decreased adsorption capacity and cannot be used to adsorb silver ions in strongly acidic wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of silver ion adsorption material, comprises the steps:

[0022] (1) Under the condition of nitrogen or inert gas protection, rhodanine derivative monomer, N,N'-methylenebisacrylamide, thermal initiator and polar organic solvent are mixed to obtain a raw material mixture; the rhodanine Ning derivative monomer is 3-allyl rhodanine or 3-butenyl rhodanine;

[0023] (2) Maintaining an atmosphere protected by nitrogen or an inert gas, performing thermal polymerization to obtain a silver ion adsorption material.

[0024] In the present invention, the rhodanine derivative monomer, N,N'-methylenebisacrylamide, thermal initiator and polar organic solvent are mixed under the protection condition of nitrogen or inert gas to obtain a raw material mixture.

[0025] In the present invention, there is no special limitation on the mixing order of the rhodanine derivative monomer, N,N'-methylenebisacrylamide, thermal initiator and pol...

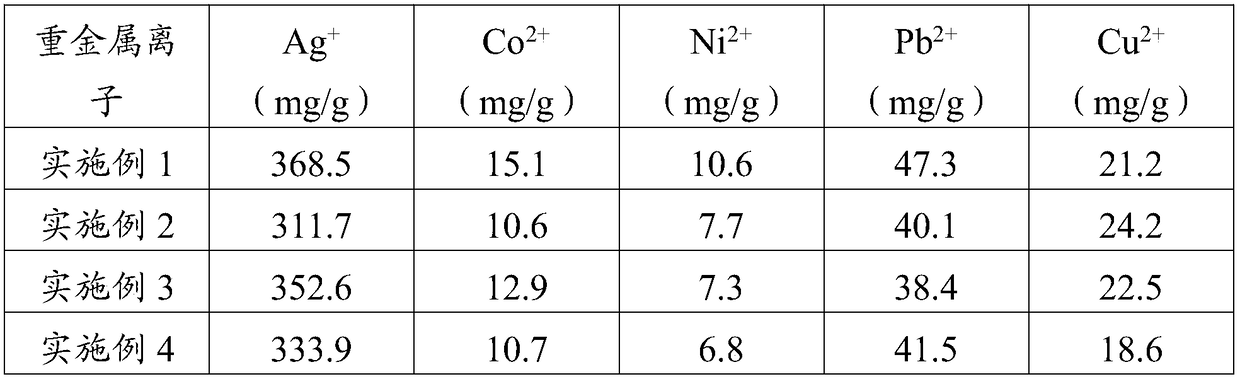

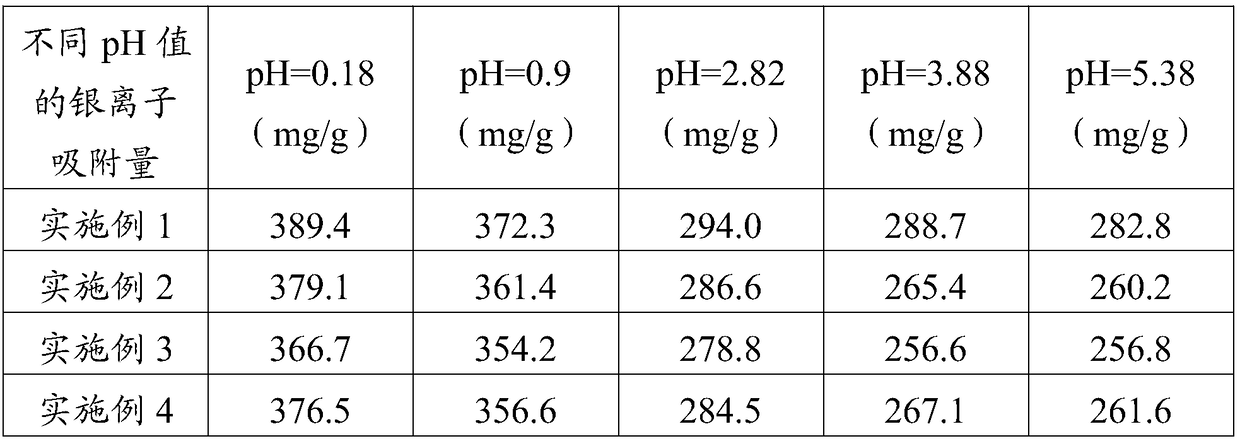

Embodiment 1

[0056] (1) Add 50mL of methanol to a 100mL flask, vacuumize to -0.08MPa, then feed nitrogen, add 5mmol (that is, 0.8663g) of 3-allyl rhodanine under stirring, and after the dissolution is complete, a transparent and bright Yellow solution, namely 3-allyl rhodanine solution;

[0057] (2) Add 1mmol (ie 0.1542g) N,N'-methylenebisacrylamide to the 3-allyl rhodanine solution, stir to dissolve; then quickly add 2mmol (ie 0.3284g) AIBN, and vacuum to -0.07MPa, then feed nitrogen, stir evenly, and obtain a raw material mixture;

[0058] (3) Under the protection of nitrogen, the temperature was raised to 60°C at a heating rate of 3°C / min, and condensed and refluxed for 3 hours;

[0059] (4) Cool the reaction mixture to room temperature, and then separate it by suction filtration to obtain a solid product; wash the solid product three times with methanol, and the stirring time for each washing is 10 min; dry the washed solid product at 60°C Afterwards, the silver ion adsorption materi...

Embodiment 2

[0062] (1) Add 50mL of methanol to a 100mL flask, vacuumize to -0.09MPa, then feed nitrogen, add 5mmol (that is, 0.8663g) of 3-allyl rhodanine under stirring, and obtain a transparent bright Yellow solution, namely 3-allyl rhodanine solution;

[0063] (2) Add 3mmol (ie 0.4626g) N,N'-methylenebisacrylamide to the 3-allyl rhodanine solution, stir to dissolve; then quickly add 2mmol (ie 0.3284g) AIBN, and vacuum to -0.09MPa, then feed nitrogen, stir evenly, and obtain a raw material mixture;

[0064] (3) Under the protection of nitrogen, the temperature was raised to 60°C at a heating rate of 3°C / min, and condensed and refluxed for 3 hours;

[0065] (4) Cool the reaction mixture to room temperature, and then separate it by suction filtration to obtain a solid product; wash the solid product three times with methanol, and the stirring time for each washing is 15 min; dry the washed solid product at 60°C Afterwards, the silver ion adsorption material is obtained through grinding....

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com