Preparation method and application of hollow composition template molecularly imprinted polymer micro-shell

A technology of molecular imprinting and combined templates, applied in separation methods, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of limiting the application range of hollow molecular imprinting materials, and achieve the effect of fast adsorption rate and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a hollow combined template molecularly imprinted polymer microshell, comprising the following steps:

[0032] S1. Preparation of polystyrene nanoparticles: First, nitrogen gas is introduced into an aqueous solution of sodium bicarbonate with a concentration of 1-2 mg / mL, and after being heated in a water bath to 55°C-65°C, acrylic acid, styrene and ammonium persulfate are added in sequence, The weight ratio of sodium bicarbonate aqueous solution, acrylic acid, styrene, and ammonium persulfate is: (80-120): (0.5-1.5): (4.0-6.0): (0.05-0.1). The reaction system is mechanically stirred at 350-450rmp, polymerized at 68-72°C for 15-25h, and centrifuged at 8000-10000rpm for 5-10min at room temperature to remove the supernatant to obtain polystyrene nanoparticles; wash with ethanol Polystyrene nanoparticles are dried 3 to 5 times at 40 to 60°C to constant weight for later use;

[0033] S2. Preparation of pre-assembly solution: use sulfadiazine and cipro...

Embodiment 1

[0038] This example relates to a method for preparing a hollow combined template molecularly imprinted polymer microshell that is selective for sulfonamide antibiotics and quinolone antibiotics.

[0039] A method for preparing a hollow combined template molecularly imprinted polymer microshell (h-MIMs), comprising the following steps:

[0040] S1. Preparation of polystyrene nanoparticles: prepare monodisperse carboxylic acid-modified polystyrene nanoparticles by emulsion polymerization; first, add 100 g of sodium bicarbonate aqueous solution with a concentration of 1.5 mg / mL into a three-necked bottle and pass through Inject nitrogen, heat up to 60°C in a water bath, add 1g of acrylic acid, 5g of styrene and 0.08g of ammonium persulfate in sequence, and polymerize at 70°C for 20h under mechanical stirring at 400rmp, centrifuge at 10,000rpm for 10min at room temperature, and remove the upper layer clear liquid to obtain polystyrene nanoparticles; wash the polystyrene nanopartic...

Embodiment 2

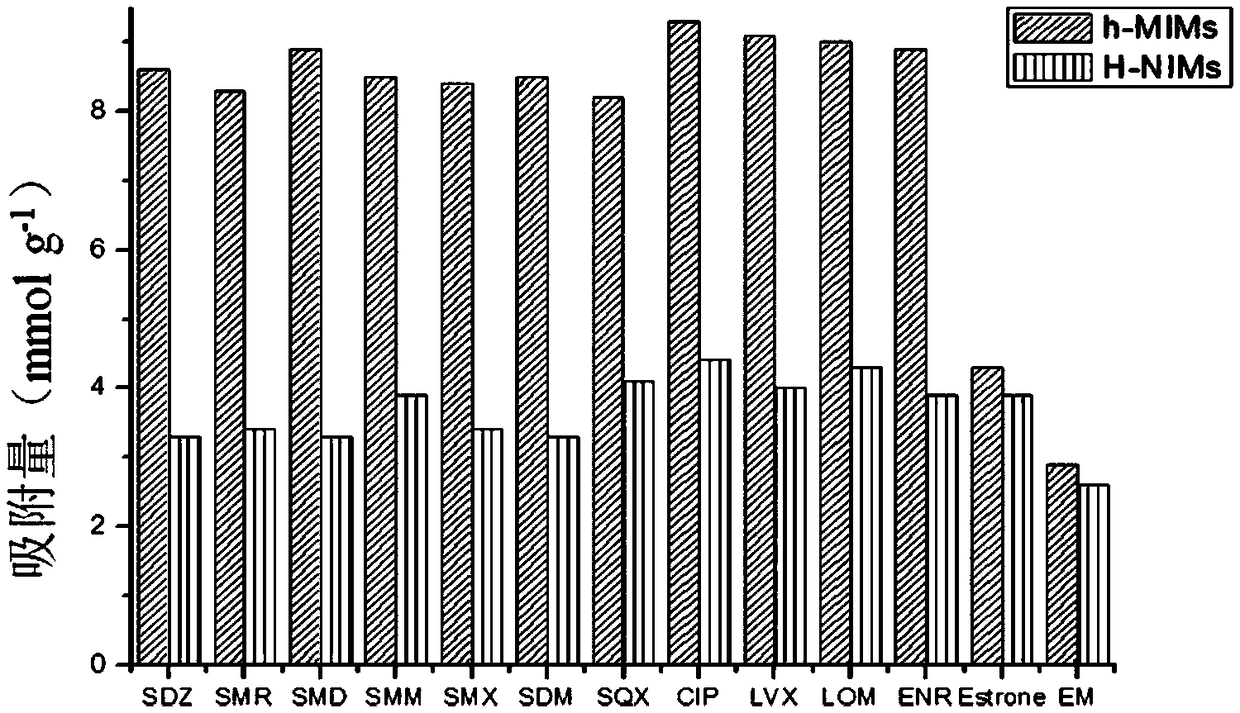

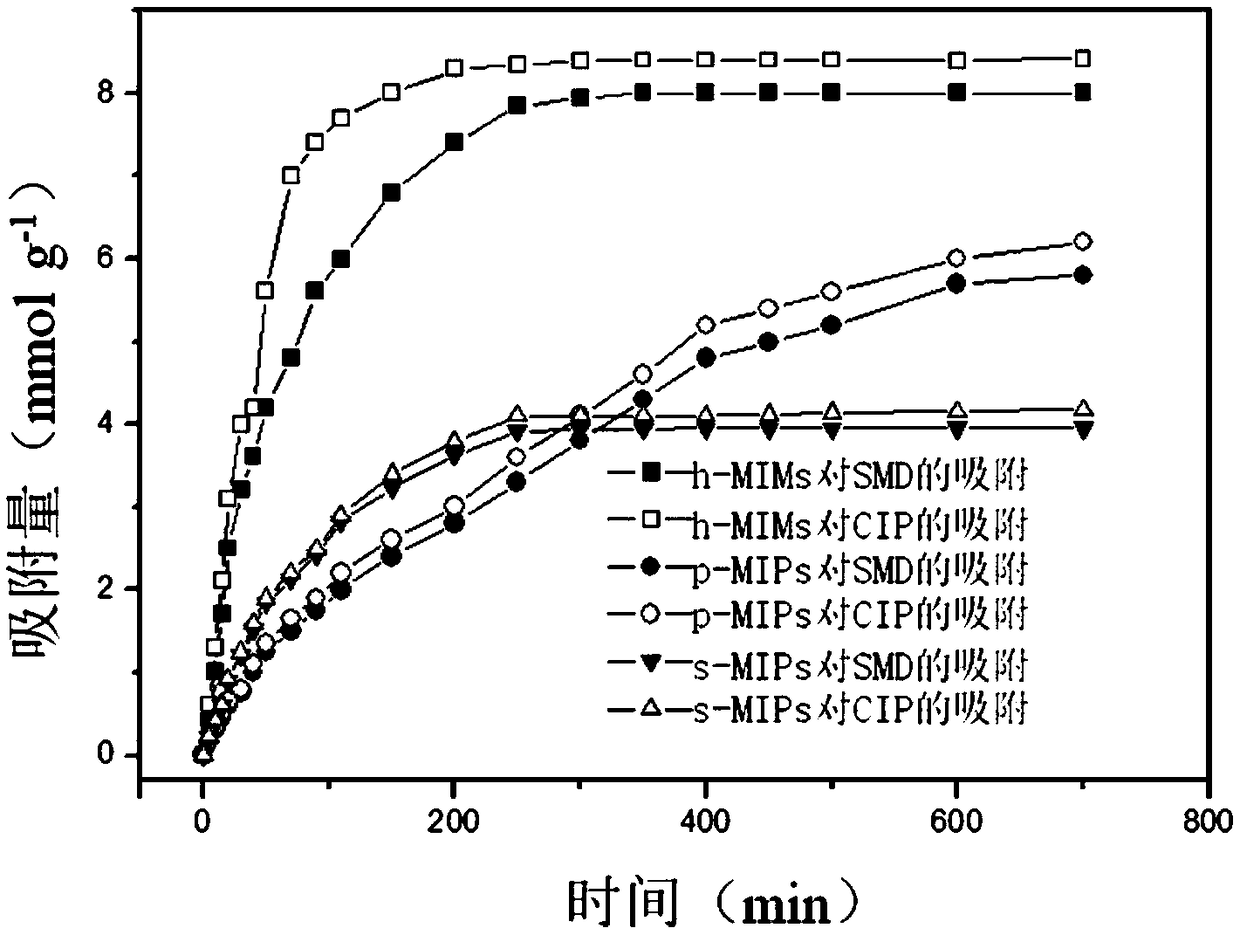

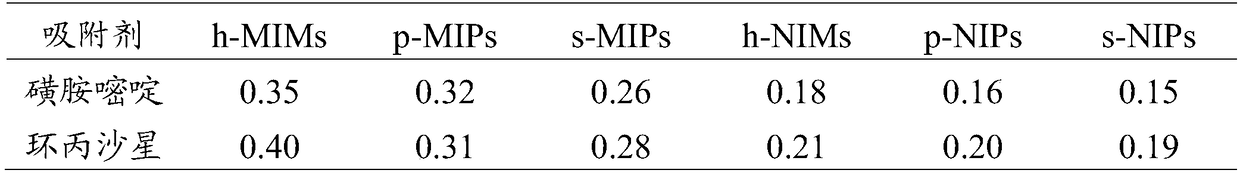

[0046] In order to verify the selective adsorption performance of the h-MIMs prepared in the examples of the present invention on template molecules, molecularly imprinted materials were prepared as a control according to the following method.

[0047] 1. The preparation of hollow non-molecularly imprinted microshells (h-NIMs) adopts the following steps:

[0048] ① Preparation of carboxylic acid-modified polystyrene nanoparticles: the method is the same as step S1 of Example 1 of the present invention;

[0049] ② Preparation of non-molecularly imprinted nanospheres: Take 0.4g of polystyrene nanoparticles prepared in step ① and disperse them in 100g, 0.25g mL -1 In the sodium lauryl sulfate aqueous solution, emulsify under the action of stirring for 24 hours; Subsequently, add 6g divinylbenzene and 0.08g azobisisobutylcyanide, initiate polymerization reaction; In order to improve the morphology characteristic of preparation material, The polymerization reaction was first react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com