Stratified hydroxide composite material and preparation method thereof

A layered hydroxide and composite material technology, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve the problems of limited application range, lack of selectivity of guest molecules, etc., and achieve high specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the above-mentioned hydroxide composite material, comprising: A) roasting the layered hydroxide to obtain a composite oxide; B) mixing the composite oxide, sulfonated calixarene and water, and reacting Finally, the layered hydroxide composite material is obtained.

[0035] All the raw materials of the present invention have no special limitation on their sources, they can be purchased on the market or made by themselves. The layered hydroxide and sulfonated calixarene are all the same as above, and will not be repeated here; the water is preferably exhausted through an inert gas such as nitrogen, which can avoid the impact of oxygen and other gases on the layered layer. The effect of hydroxide.

[0036] The preparation methods of the layered hydroxide and sulfonated calixarene can be prepared by methods well known to those skilled in the art, and there is no special limitation.

[0037] The invention utilizes ...

Embodiment 1

[0045] 1.1 Add 10mmol (1.363g) ZnCl 2 , 5mmol (1.207g) AlCl 3 ·6H 2 O. 35mmol (2.102g) urea was mixed with 1L water, under the condition of reflux at 100°C, after continuous stirring for 24h, the precipitate was filtered, washed with deionized water and absolute ethanol, and dried in vacuum at 40°C to obtain ZnAl-CO 3 layered double hydroxides.

[0046] 1.2 Combine the ZnAl-CO obtained in 1.1 3 The layered double metal hydroxide was calcined at 400°C for 4 hours in air to obtain a composite oxide.

[0047] 1.3 Add 0.1g of sulfonated thiacalix[4]arene to 10ml of exhaust water, then add 0.1g of the composite oxide obtained in 1.2, seal it, stir it magnetically for 48 hours, centrifuge, wash with exhaust water three times, and place Dry in air to obtain a layered hydroxide composite material.

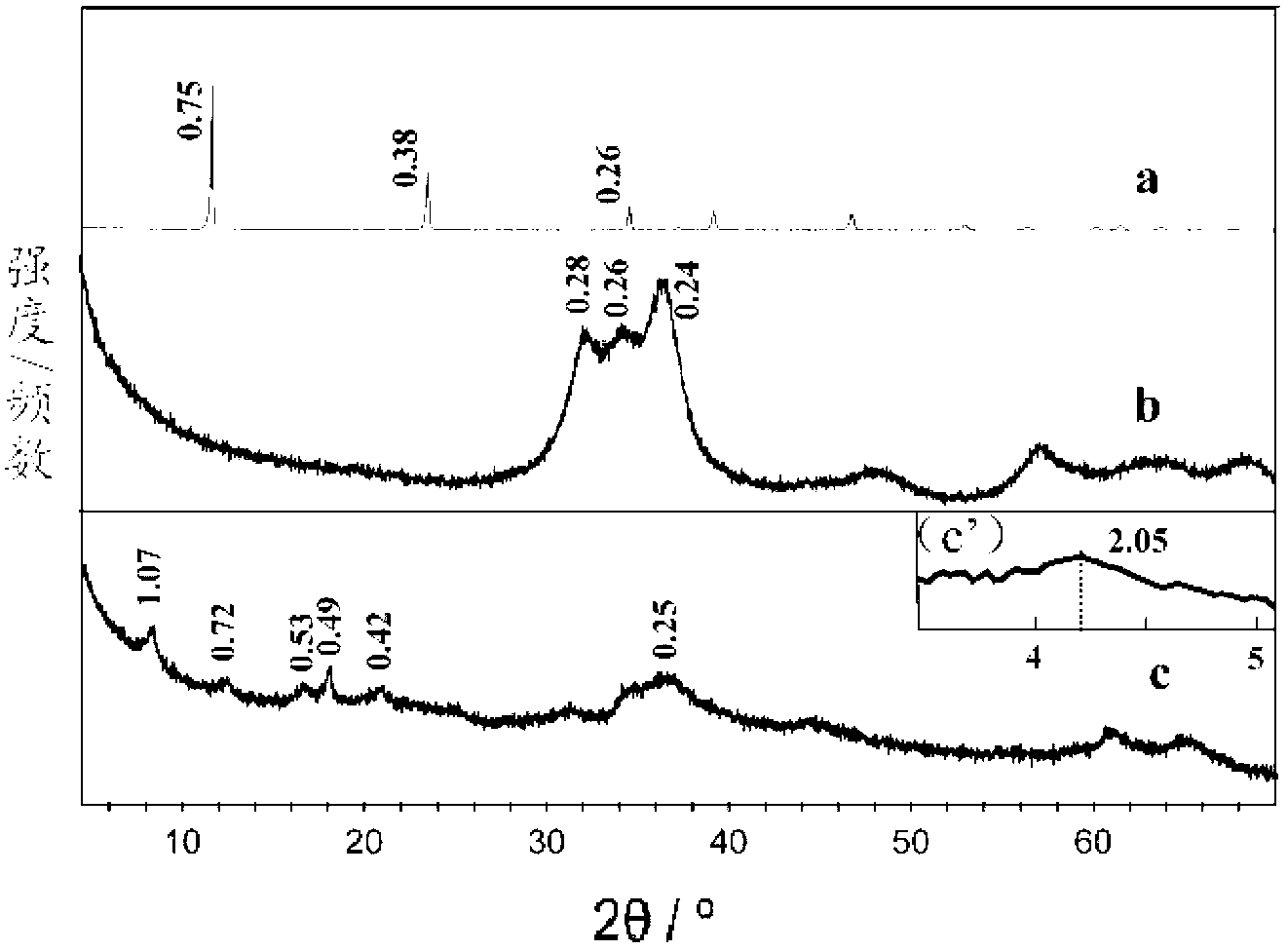

[0048] Using X-ray diffractometer to analyze the ZnAl-CO obtained in 1.1 3 Layered double metal hydroxide, the composite oxide obtained in 1.2 and the layered hydroxide composite mat...

Embodiment 2

[0051] 2.1 Add 10mmol (1.363g) ZnCl 2 , 5mmol (1.207g) AlCl 3 ·6H 2 O. 35mmol (2.102g) urea was mixed with 1L water, under the condition of reflux at 100°C, after continuous stirring for 24h, the precipitate was filtered, washed with deionized water and absolute ethanol, and dried in vacuum at 40°C to obtain ZnAl-CO 3 layered double hydroxides.

[0052] 2.2 The ZnAl-CO obtained in 2.1 3 The layered double metal hydroxide was calcined at 400°C for 4 hours in air to obtain a composite oxide.

[0053] 2.3 Add 0.05g of sulfonated thiacalix[4]arene to 10ml of degassed water, then add 0.1g of the composite oxide obtained in 2.2, seal it, stir it magnetically for 48 hours, centrifuge, wash with degassed water three times, and place Dry in air to obtain a layered hydroxide composite material.

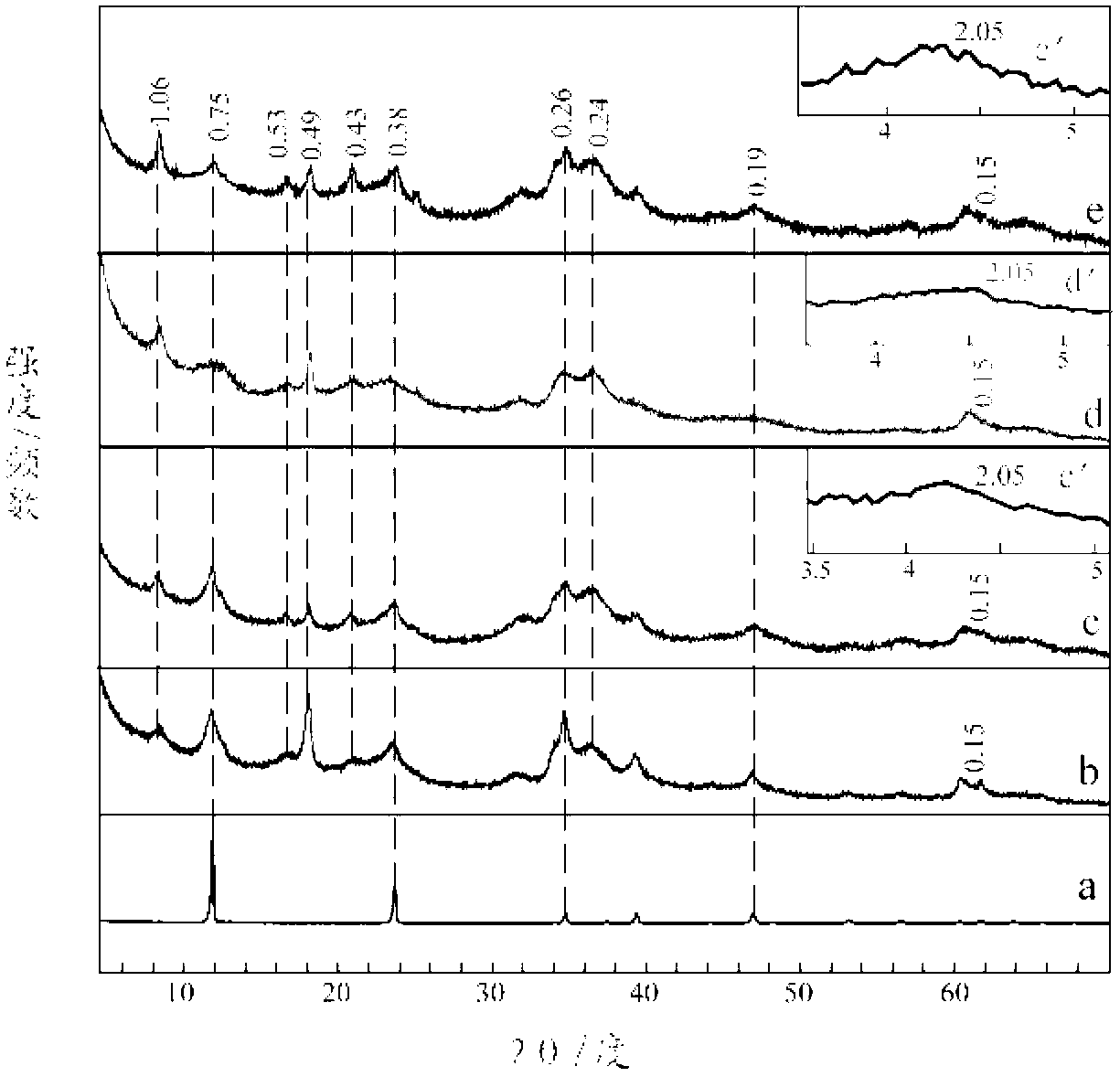

[0054] Utilize X-ray diffractometer to analyze the layered hydroxide composite material obtained in 2.3, obtain its X-ray diffraction pattern, as figure 2 Shown, where b is the layered h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com