OA up-and-down partition type membrane biological reaction sewage treatment system and method

A sewage treatment system, membrane biological reaction technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, water treatment parameter control, etc., can solve the problem of low biochemical efficiency of facultative oxygen system and high energy consumption of sewage treatment system , high operating costs, to achieve the effect of improving the upper biochemical reaction rate, reducing the cost of sewage treatment, and improving the biochemical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

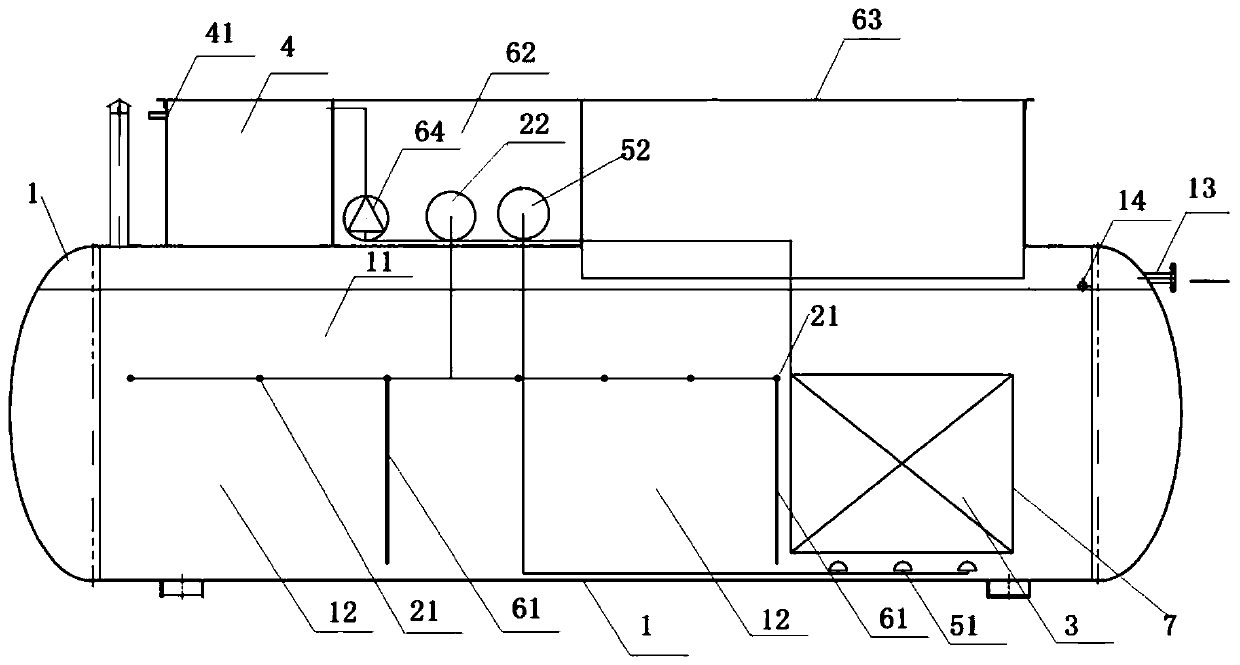

[0033] This embodiment provides an upper and lower partition type membrane bioreaction sewage treatment system, such as figure 1 As shown, it includes a treatment tank 1, a filter membrane module, an upper aeration device and a lower aeration device.

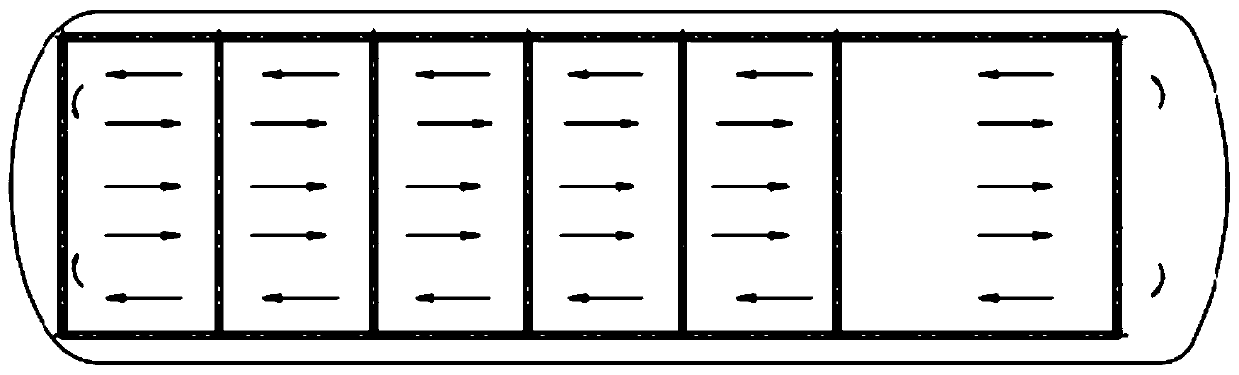

[0034] Wherein, the treatment tank 1 includes an upper layer and a lower layer, the upper layer of the treatment tank 1 is an aerobic layer 11, and the lower layer of the treatment tank 1 is an anaerobic layer 12; the filter membrane module is arranged on the lower layer of the treatment tank 1 for filtering the sewage in the treatment tank 1; The upper layer aeration device includes a plurality of aeration pipes 21 , and the plurality of aeration pipes 21 are arranged at intervals on the upper layer of the treatment pool 1 along the width or length direction of the treatment pool 1 to form a water circulation in the upper layer of the treatment pool 1 . The lower aeration device is arranged under the filter membrane module.

...

Embodiment 2

[0052] The present invention provides a kind of method adopting the OA upper and lower partition type membrane bioreaction sewage treatment system of embodiment 1, comprises the following steps:

[0053] The sewage first enters the pre-hydrolysis acidification tank, undergoes anaerobic treatment, and then flows into the OA upper and lower partition membrane bioreaction sewage treatment system;

[0054] Sewage enters the upper aerobic layer where nitrification takes place, the nitrogen in the sewage is converted into nitrate and nitrite by nitrifying bacteria, and the phosphorus in the sewage is absorbed by the bacteria;

[0055] After the nitrification reaction, the upper layer of sewage gradually enters the lower anaerobic layer for denitrification reaction. The denitrification reaction converts nitrate and nitrite in the sewage into nitrogen gas, and the bacteria release free phosphine at the same time during the denitrification reaction;

[0056] After denitrification treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com