Method for producing organic fertilizer from agricultural waste

A technology of agricultural waste and organic fertilizer, which is applied in the preparation of organic fertilizer, organic fertilizer, and bio-organic part treatment, etc., can solve problems that affect the absorption and utilization of nutrient release crops, unfavorable large-scale processing and utilization, and respiratory center poisoning, etc., to achieve The content of harmful substances is reduced, the particle size is good, and the effect of increasing the particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

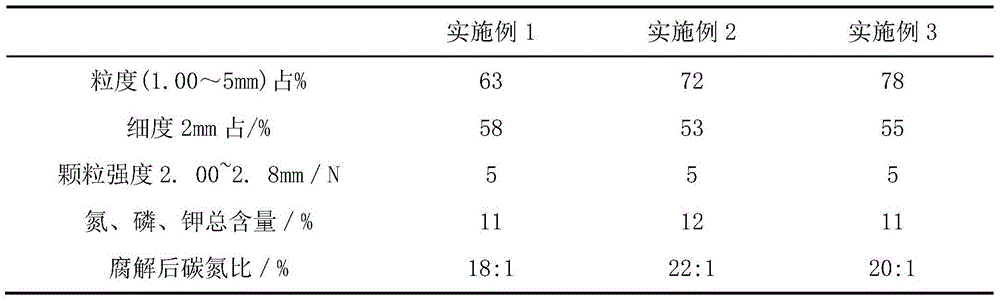

Examples

Embodiment 1

[0018] The method for producing organic fertilizer from agricultural waste of the present embodiment may further comprise the steps:

[0019] Take 23kg of livestock and poultry manure and 16kg of crop straw to prepare agricultural waste fermentation base material with a carbon-to-nitrogen ratio of 32:1, adjust the water content of the agricultural waste to be decomposed to 65%, and inoculate the fast-rot microbial agent for fermentation. The oxygen supply in the agricultural waste during the fermentation process is 0.5m 3 / d·kg, after 9 days of fermentation, dry to a water content of 30-35%, granulate and dry;

[0020] Wherein, the content of yeast in the described fast-rot microbial inoculum is not less than 1×10 7 CFU / g; the content of Distosporium thermophiles is not less than 0.5×10 7 CFU / g; the content of nitrogen-fixing bacteria rotunda is not less than 1×10 7 CFU / g; Aspergillus niger content not less than 0.5×10 7 CFU / g.

Embodiment 2

[0022] The difference between the method for producing organic fertilizer with agricultural waste in this embodiment and Example 1 is that: the livestock and poultry manure is 21 kg, the crop straw is 16 kg, and the carbon-nitrogen ratio of the obtained agricultural waste fermentation base material is It is 34:1; the described water content is 55%; the oxygen supply in the agricultural waste in the described fermentation process is 0.8m 3 / d·kg, the fermentation time is 7d;

Embodiment 3

[0024] The difference between the method for producing organic fertilizer with agricultural waste in this embodiment and Example 1 is that: the livestock and poultry manure is 22.2 kg, the crop straw is 16 kg, and the obtained agricultural waste fermentation base material carbon nitrogen The ratio is 33:1; the water content is 60%; the oxygen supply in the agricultural waste in the fermentation process is 1m 3 / d·kg; the fermentation time is 8d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com