Metallographic preparation method of coating

A technology for coating and metallographic samples, applied in the field of metallographic preparation, can solve problems such as large differences, and achieve the effect of improving authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

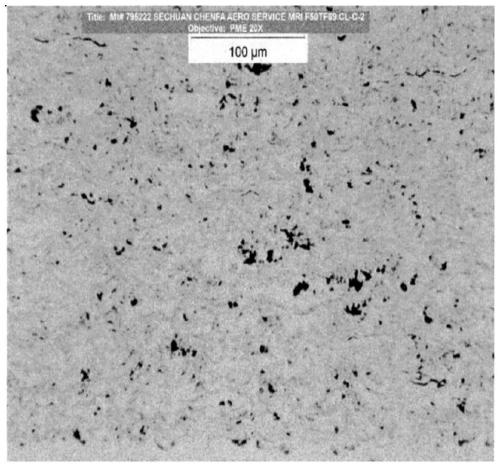

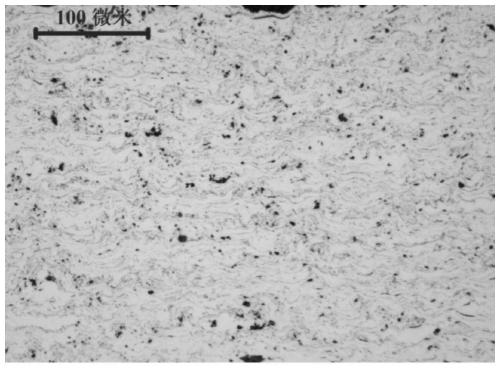

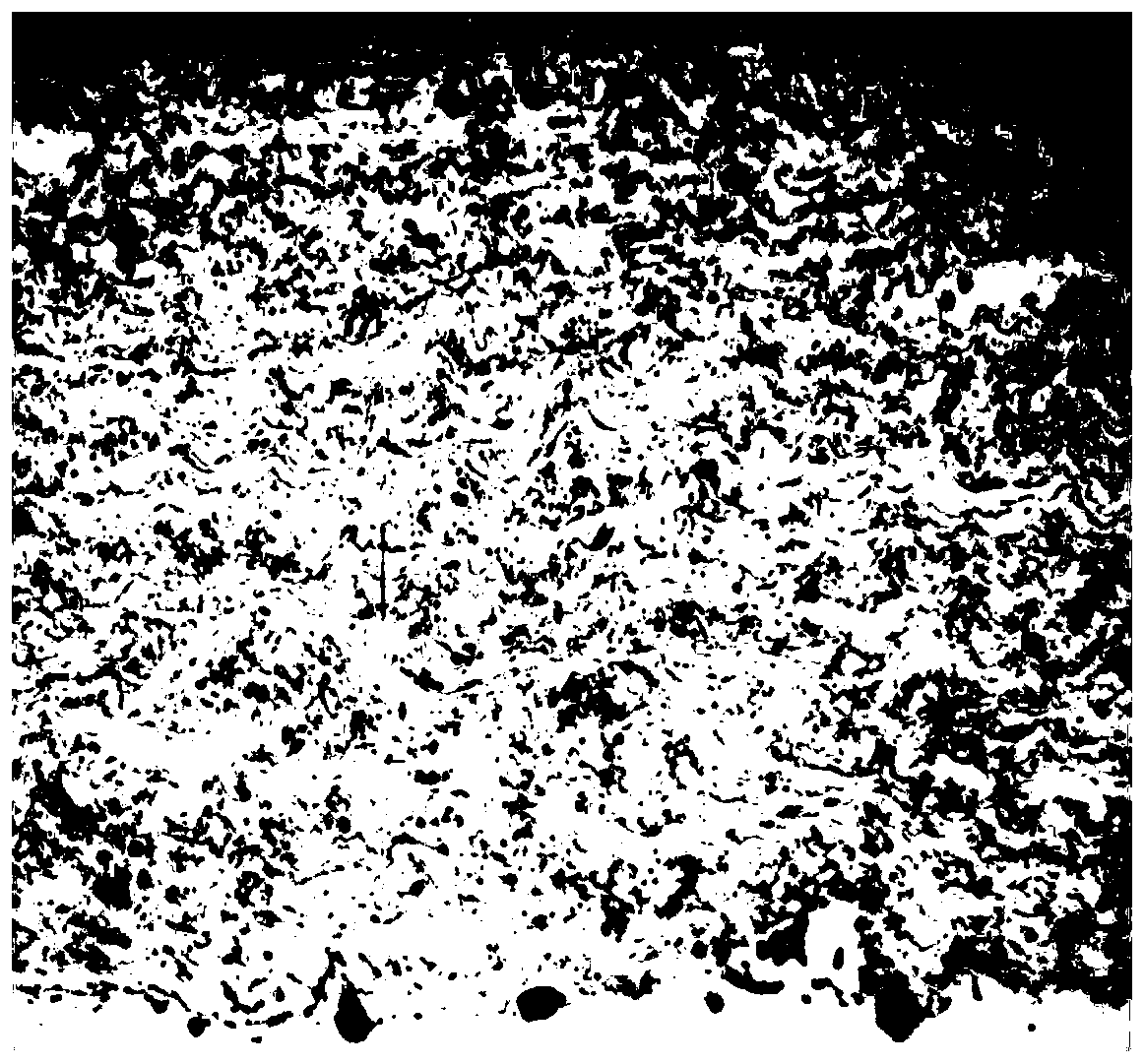

Image

Examples

Embodiment 1

[0029] A metallographic preparation method, comprising the steps of:

[0030] (1) Get the sample that is sprayed with cobalt-molybdenum-chromium-silicon coating, put it into dehydrated alcohol and clean;

[0031] (2) Hot-mount the sample after cleaning in step (1), then remove the affected area of the coating damage produced in the cutting process, and remove the thickness to be 1.5mm to obtain a metallographic sample;

[0032] (3) Grinding the metallographic samples processed in step (2) on 180#, 220#, 320#, 500#, 800#, 1200# and 4000# silicon carbide sandpaper successively, each type of sandpaper The grinding pressure is 20N / mt, the grinding speed is 120r / min, and the grinding time is 20s;

[0033] (4) The metallographic sample treated in step (3) is polished on a lint-free cloth made of TexMetC medium-hardness non-woven fiber resin with a diamond compound as a lubricant, and 1 μm is smeared on the lint-free cloth during polishing. diamond paste and 1μm diamond suspensio...

Embodiment 2

[0036] A metallographic preparation method, comprising the steps of:

[0037] (1) Get the sample that is sprayed with cobalt-molybdenum-chromium-silicon coating, put it into dehydrated alcohol and clean;

[0038] (2) hot mount the sample after cleaning in the step (1), then remove the affected area of the coating damage produced in the cutting process, the thickness of the removed part is 1.7mm, to obtain a metallographic sample;

[0039] (3) Grinding the metallographic samples processed in step (2) on 180#, 220#, 320#, 500#, 800#, 1200# and 4000# silicon carbide sandpaper successively, each type of sandpaper The grinding pressure is 30N / mt, the grinding speed is 180r / min, and the grinding time is 40s;

[0040] (4) The metallographic sample treated in step (3) is polished on a lint-free cloth made of TexMetC medium-hardness non-woven fiber resin with a diamond compound as a lubricant, and 1 μm is smeared on the lint-free cloth during polishing. Diamond abrasive paste and 1...

Embodiment 3

[0043] A metallographic preparation method, comprising the steps of:

[0044] (1) Get the sample that is sprayed with cobalt-molybdenum-chromium-silicon coating, put it into dehydrated alcohol and clean;

[0045] (2) hot mount the sample after cleaning in the step (1), then remove the affected area of the coating damage produced in the cutting process, the thickness of the removed part is 1.6mm, to obtain a metallographic sample;

[0046](3) Grinding the metallographic samples processed in step (2) on 180#, 220#, 320#, 500#, 800#, 1200# and 4000# silicon carbide sandpaper successively, each type of sandpaper The grinding pressure is 25N / mt, the grinding speed is 150r / min, and the grinding time is 30s;

[0047] (4) The metallographic sample treated in step (3) is polished on a lint-free cloth made of TexMetC medium-hardness non-woven fiber resin with a diamond compound as a lubricant, and 1 μm is smeared on the lint-free cloth during polishing. Diamond abrasive paste and 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com