A kind of positive electrode material of lithium-sulfur battery and preparation method thereof

A cathode material, lithium-sulfur battery technology, applied in lithium batteries, battery electrodes, and sulfur preparation/purification, etc., can solve the problems of non-commercialization of lithium-sulfur batteries, reduced capacity of lithium-sulfur batteries, and obstacles to electron transport, and achieve inhibition of lithium-sulfur batteries. Shuttle effect, improved cycle stability and rate capability, and the effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

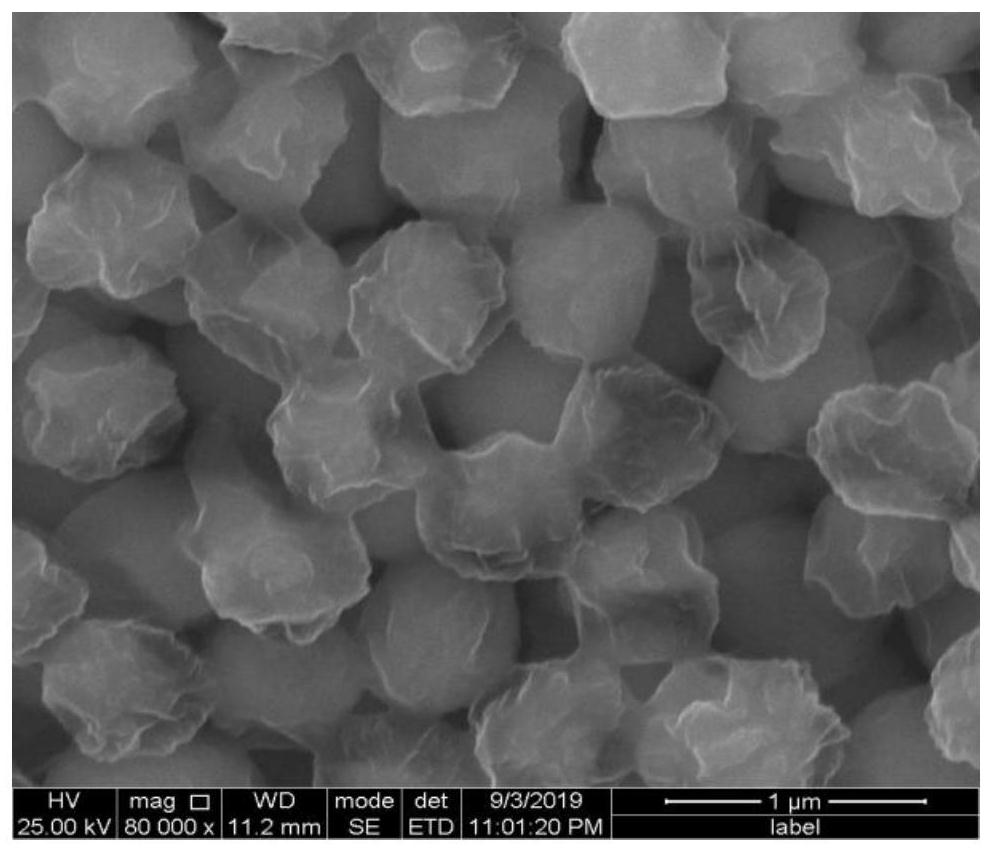

[0030] (1) Dissolve 0.04g of polyvinylpyrrolidone (K-30) and 2.00g of sodium thiosulfate pentahydrate in 200mL of deionized water and stir evenly, add 1.6mL of concentrated hydrochloric acid (mass fraction of 37%) and magnetically stir to react. After 2h, centrifugation (centrifugation speed 4200r / min, centrifugation time 5min, the same below), washing and drying are performed in sequence to obtain hollow sulfur balls;

[0031] (2) Disperse 100 mg of hollow sulfur spheres in 50 mL of deionized water, add 100 mg of nickel nitrate hexahydrate and 200 mg of hexamethylene tetramine, ultrasonicate for 1 h under the ultrasonic power of 300 W, and then under the condition of 95 °C at 300 r / The hydrothermal stirring reaction was carried out at a stirring rate of min for 6 h, followed by cooling, centrifugation, washing, and drying in sequence after cooling to room temperature to obtain nickel hydroxide-coated hollow sulfur spheres (HS@Ni(OH) 2 );

[0032] (3) 100 mg of nickel hydrox...

Embodiment 2

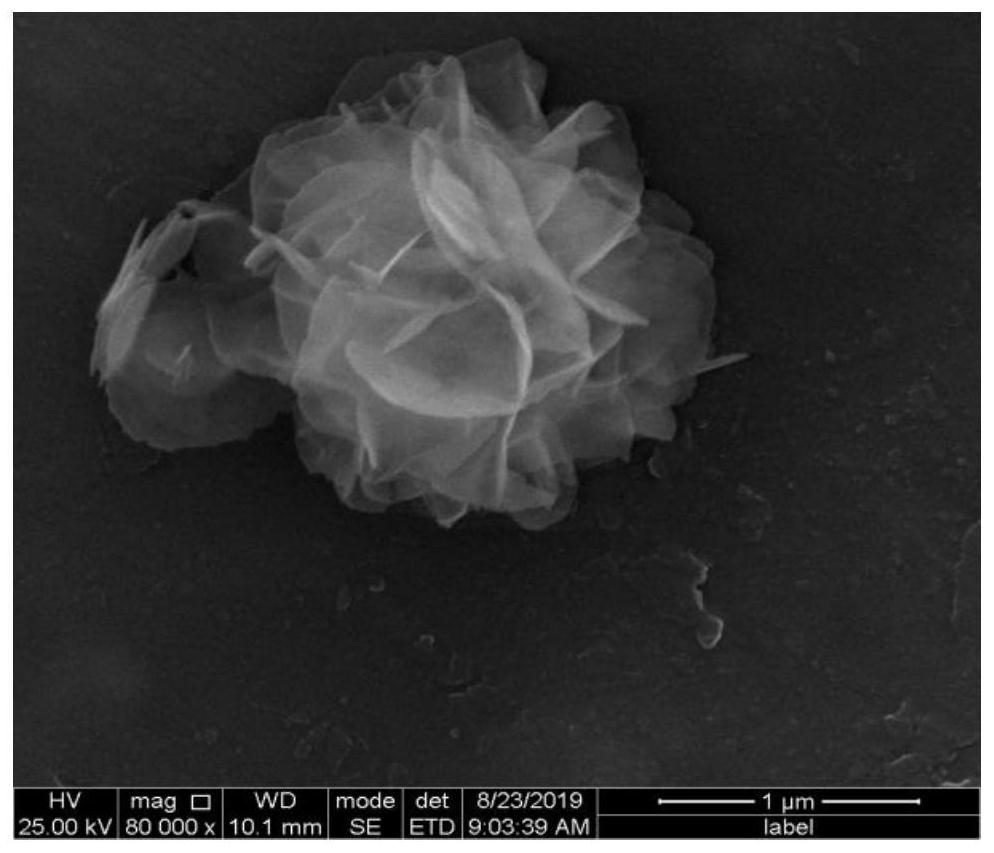

[0036] (1) Dissolve 0.04g of polyvinylpyrrolidone (K-30) and 2.00g of sodium thiosulfate pentahydrate in 200mL of deionized water and stir evenly, add 1.6mL of concentrated hydrochloric acid (mass fraction of 37%) and magnetically stir to react. After 2 hours, centrifugation (centrifugation speed 4200r / min, centrifugation time 5min, the same below), washing and drying are performed in sequence to obtain hollow sulfur spheres;

[0037] (2) Disperse 100 mg of hollow sulfur spheres in 75 mL of deionized water, add 100 mg of nickel nitrate hexahydrate and 200 mg of hexamethylene tetramine, ultrasonicate for 1 h under the ultrasonic power of 300 W, and then under the condition of 95 ° C at 300 r / The hydrothermal stirring reaction was carried out at a stirring rate of min for 6 h, then the temperature was lowered, and then centrifugation, washing and drying were carried out in sequence after cooling to room temperature to obtain hollow sulfur spheres coated with nickel hydroxide;

...

Embodiment 3

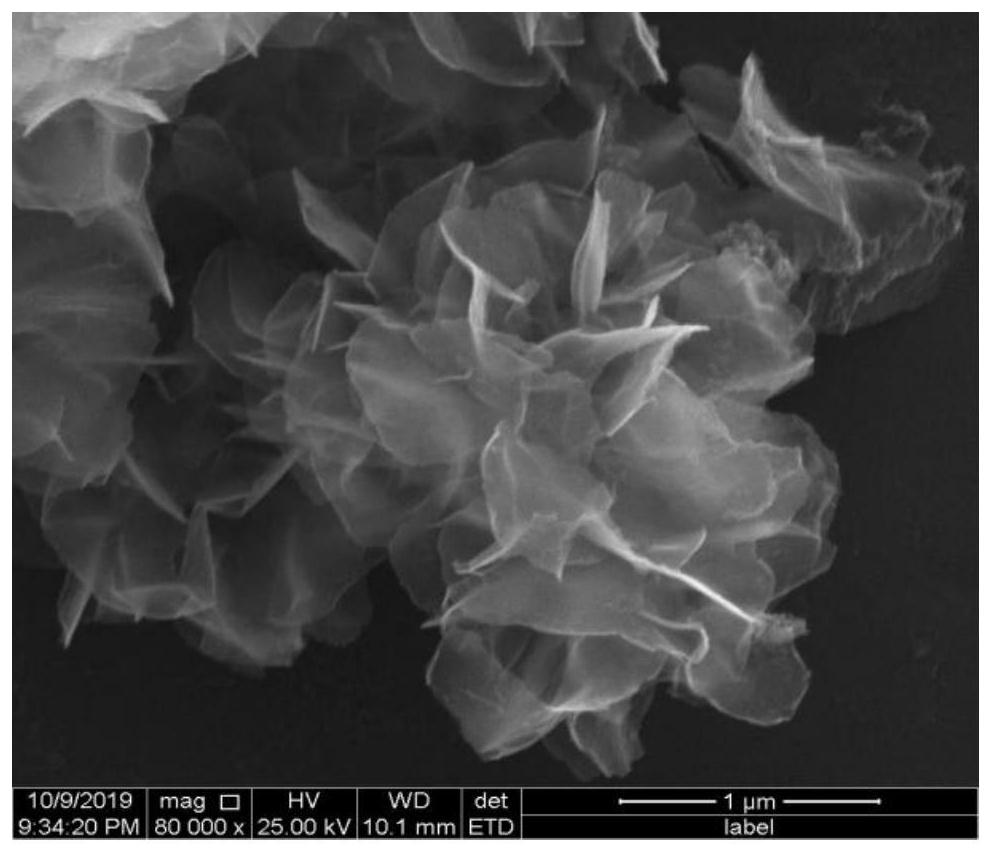

[0042] (1) Dissolve 0.04g of polyvinylpyrrolidone (K-30) and 2.00g of sodium thiosulfate pentahydrate in 200mL of deionized water and stir evenly, add 1.6mL of concentrated hydrochloric acid (mass fraction of 37%) and magnetically stir to react. After 2 hours, centrifugation (centrifugation speed 4200r / min, centrifugation time 5min, the same below), washing and drying are performed in sequence to obtain hollow sulfur spheres;

[0043] (2) Disperse 100 mg of hollow sulfur spheres in 75 mL of deionized water, add 100 mg of nickel nitrate hexahydrate and 200 mg of hexamethylene tetramine, ultrasonicate for 1 h under the ultrasonic power of 300 W, and then under the condition of 95 ° C at 300 r / The hydrothermal stirring reaction was carried out at a stirring rate of min for 6 h, then the temperature was lowered, and then centrifugation, washing and drying were carried out in sequence after cooling to room temperature to obtain hollow sulfur spheres coated with nickel hydroxide;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com