A gain device and laser based on micro-nano structured semiconductor thin film

A micro-nano structure and semiconductor technology, applied in the field of lasers, can solve the problems affecting the output power and efficiency of the laser, the total reflection of the laser cannot be well solved, and the output of high beam quality cannot be achieved, so as to improve the efficiency of the laser, realize the beam quality, The effect of a large mold field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

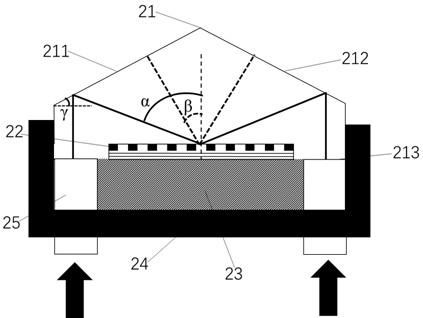

[0067] This embodiment provides a semiconductor thin film with micro-nano structure, such as figure 1 As shown, from top to bottom, including window layer 223, microstructure layer 221 and multiple quantum well layer 222;

[0068] The multi-quantum well layer 222 includes four stacked barrier layers GaAs (each barrier layer GaAs (gallium arsenide) has a thickness of 250 nm) and three well layers InGaAs (each well layer InGaAs (indium gallium arsenide) ) with a thickness of 10 nm), the well layer is located between different barrier layers;

[0069] The microstructure layer 221 is a one-dimensional grating structure with a grating period of 550 nm, a duty ratio of 0.5, and an etching depth of 300 nm.

[0070] The material of the window layer 223 is SiO 2 , with a thickness of 5 nm. The window layer 223 is located on the upper end of the micro-nano-structured semiconductor film 22 and plays a role of protecting the micro-structured layer 221 .

[0071] In this embodiment, th...

Embodiment 2

[0073] This embodiment provides a gain device based on a micro-nano-structured semiconductor thin film, such as figure 2 As shown, it includes a prism window 21 and a micro-nano-structured semiconductor film 22 as described in Embodiment 1;

[0074] The prism window 21 includes a bottom surface 213 and a pair of inclined surfaces (the first inclined surface 211 and the second inclined surface 212) inclined relative to the bottom surface; a pair of the inclined surfaces are symmetrically distributed on the bottom surface 213, and the inclined surfaces The angles are +45º and -45º respectively; the inclined surfaces are coated with a set of film systems to achieve the purpose of reflecting the pumping light and transmitting the oscillating light;

[0075] The upper end of the micro-nano-structured semiconductor film 22 is bonded to the bottom surface 213 of the prism window 21 through photoresist technology to improve the heat dissipation efficiency of the micro-nano-structured...

Embodiment 3

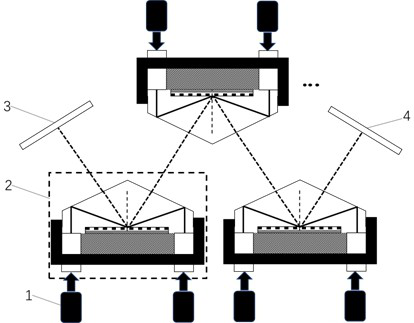

[0080] This embodiment provides a laser based on a micro-nano-structured semiconductor thin film, such as image 3 shown, including:

[0081] The active mirror group includes three active mirrors 2, and the active mirror 2 includes a gain device, a base 23, a heat sink 24 and a focusing lens 25 as described in Embodiment 2; one end of the base 23 is connected to the The lower end of the micro-nano structure semiconductor film 22 is pasted and fixed by optical glue technology, and the other end of the substrate 23 is fixedly connected to the heat sink 24 by an indium film welding process; each active mirror 2 includes two focusing lenses 25 , the focusing lens 25 is symmetrically distributed on the side of the substrate 23, the focusing lens 25 passes through the heat sink 24 and is fixedly installed on the heat sink 24; one end of the focusing lens 25 is close to the pump source 1. The other end is close to the bottom surface 213 of the prism window 21, and the pump light can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com