Method for preparing potassium chloride from carnallite

A potassium chloride and carnallite technology, which is applied in the directions of alkali metal chloride, earthwork drilling, climate change adaptation, etc., can solve the problems of high sodium chloride content, slow mining rate, impact on the quality of potassium chloride products, etc. Achieve high yield, strong adaptability, easy promotion and implementation

Active Publication Date: 2020-08-14

QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

View PDF19 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This technology is mainly aimed at low-grade solid deposits, while using MgCl 2 Solvent leaching mining at room temperature, it takes months or even years for the brine to reach equilibrium, and the mining rate is slow; and affected by the liquid-solid ratio and the composition of the ore deposit, the content of sodium chloride in the brine composition is relatively high, which has a negative impact on the prepared potassium chloride product. quality makes a difference

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0091]

Embodiment 2

[0093]

Embodiment 3

[0095]

[0096]

[0097] In addition, the inventor of the present case also conducted tests with reference to the foregoing examples, using other raw materials, process operations, and process conditions mentioned in this specification, and all obtained satisfactory results.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

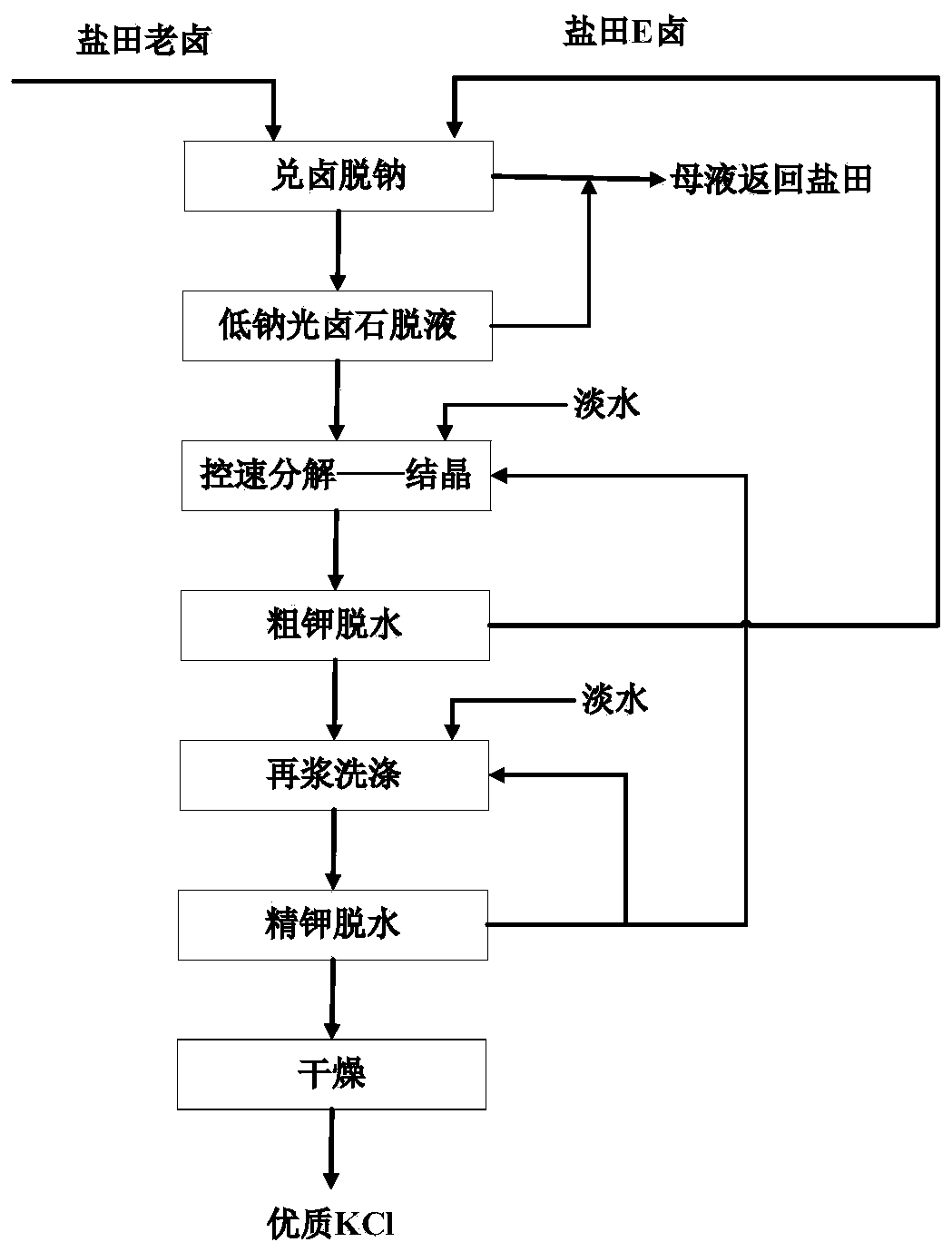

The invention discloses a method for preparing potassium chloride from carnallite. The method comprises the following steps: firstly, carrying out high-temperature water-soluble mining treatment on carnallite ore by using fresh water to obtain potassium-rich saturated brine, mixing the potassium-rich saturated brine, sylvine saturated liquid and old brine, performing brine mixing, evaporation anddecomposition treatment to obtain artificial sylvine, and finally, carrying out low-temperature selective dissolution treatment on the artificial sylvine by using fresh water to prepare potassium chloride. The carnallite ore is exploited by adopting hot water, so that the content of sodium chloride in the potassium-rich saturated brine is reduced, the artificial sylvine is prepared into potassiumchloride only by one-time low-temperature selective dissolution, so that high yield and high quality of potassium chloride are guaranteed, and unnecessary energy consumption and impurity accumulationcaused by multiple times of cyclic hot-melting crystallization treatment of sylvine are avoided, meanwhile, the method provided by the invention is suitable for carnallite ores of different grades, extremely high in adaptability, loose in technical condition and convenient for technical promotion and implementation.

Description

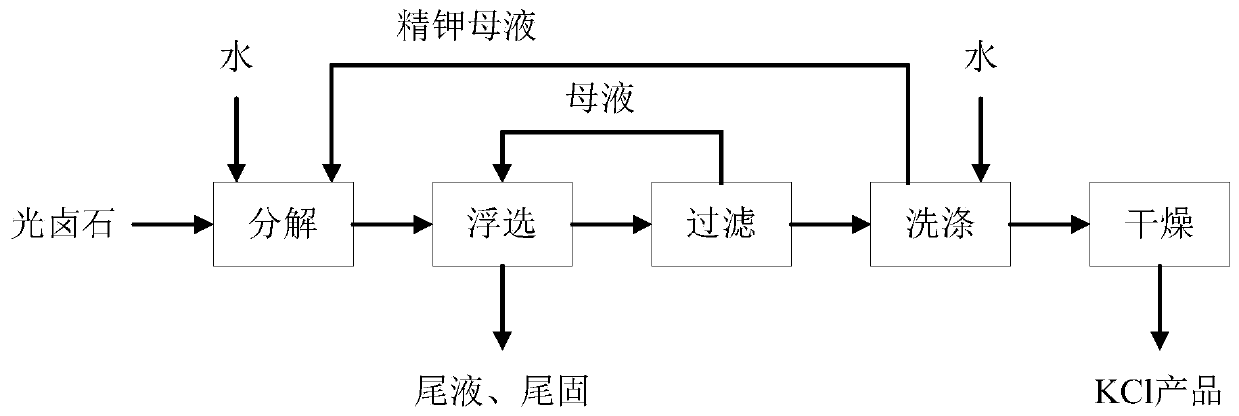

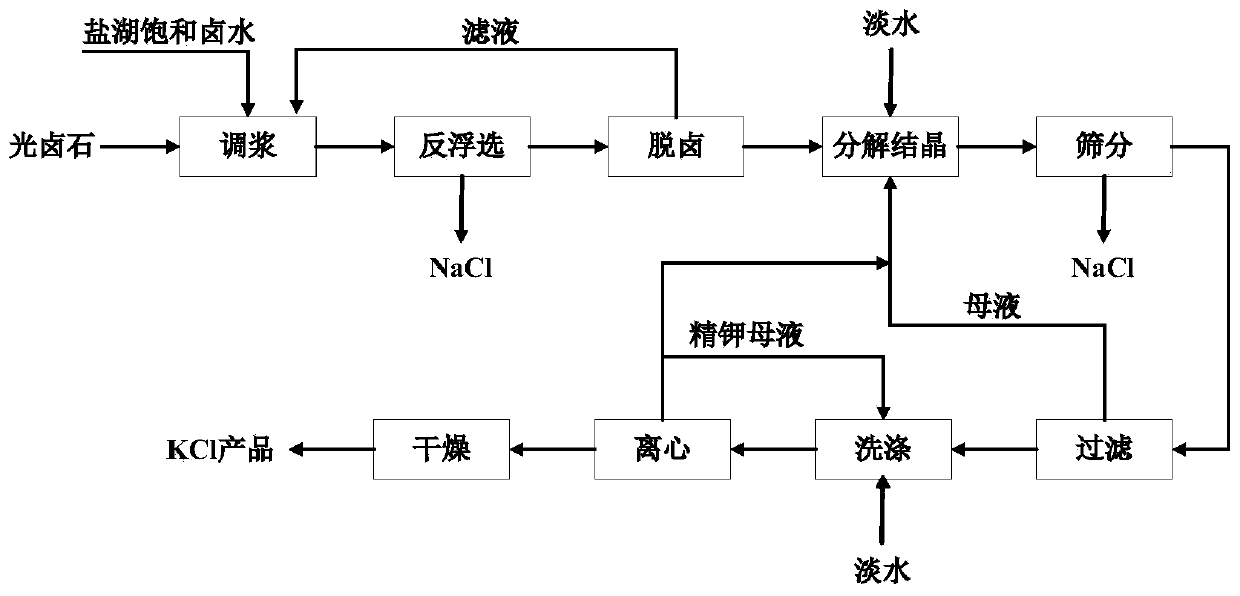

technical field [0001] The invention belongs to the technical field of inorganic salt industry, and in particular relates to a method for preparing potassium chloride by using carnallite. Background technique [0002] Potassium fertilizer is the basic material material for the stable growth of grain production. It can effectively improve the quality of agricultural products and improve the stress resistance of crops. It is one of the nutrients necessary for the growth of crops. With the reduction of arable land and the continuous growth of population, large-scale development of potassium resources and improvement of potassium fertilizer yield are of great significance to food security. [0003] The main type of potash fertilizer products is potassium chloride fertilizer, accounting for more than 90% of the total potash fertilizer. The raw materials for preparing potassium chloride fertilizer mainly include potassium halite and carnallite ore, and carnallite ore is carnallit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01D3/06E21C45/00

CPCC01D3/06E21C45/00C01P2006/80Y02A40/20C01D3/08C01F5/30

Inventor 时历杰王敏

Owner QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com