Modified road asphalt based on waste tire rubber powder and preparation method thereof

A technology for road asphalt and waste tires, which is applied to building components, building insulation materials, construction, etc., and can solve unsatisfactory mixing, paving and rolling, poor storage stability and poor compatibility of rubber powder modified asphalt Ideal and other problems, to achieve the effect of decreased penetration, good compatibility, and reduced viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

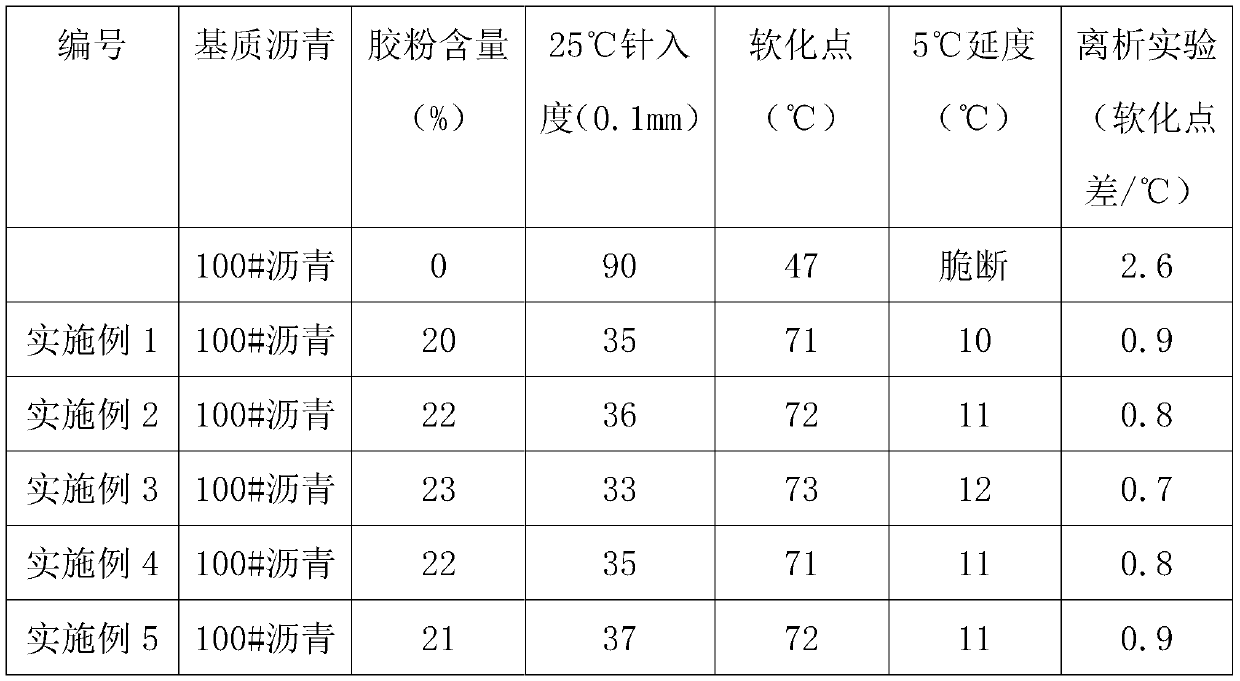

Examples

Embodiment 1

[0024] A modified road asphalt based on waste tire rubber powder, comprising the following raw materials in parts by weight: 40 parts of waste tire rubber powder, 80 parts of base asphalt, 7 parts of hydrogen peroxide, 50 parts of distilled water, phosphoric acid 7 servings of iron.

[0025] A preparation method of modified road asphalt based on waste tire rubber powder, comprising the steps of:

[0026] S1. Grinding: After the waste tire rubber is recovered, it is cleaned and ground in the factory, and ground into 150-200 mesh rubber powder to obtain waste tire rubber powder for use;

[0027] S2. Preparation of hydrogen peroxide-iron phosphate: mix hydrogen peroxide with distilled water, then add ferric sulfate, stir until dissolved, finally obtain a composite modifier, and prepare hydrogen peroxide-iron phosphate for use;

[0028] S3. Activation of waste tire rubber powder: take the waste tire rubber powder and place it in a tray, dry it in an oven at 50°C for 10-11 hours, ...

Embodiment 2

[0031] A modified road asphalt based on waste tire rubber powder, comprising the following raw materials in parts by weight: 45 parts of waste tire rubber powder, 85 parts of matrix asphalt, 8 parts of hydrogen peroxide, 55 parts of distilled water, phosphoric acid 8 servings of iron.

Embodiment 3

[0033] A modified road asphalt based on waste tire rubber powder, comprising the following raw materials in parts by weight: 50 parts of waste tire rubber powder, 90 parts of base asphalt, 9 parts of hydrogen peroxide, 60 parts of distilled water, phosphoric acid 9 servings of iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com