Preparation method of photo-thermal heat preservation type leather finishing agent

A leather finishing agent, photothermal technology, applied in leather surface treatment, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve the problem of limited heat preservation performance improvement, Problems such as poor heat insulation effect of the coating and limited reduction in thermal conductivity can achieve the effect of filling the application gap, reducing the total heat dissipation, and increasing the surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

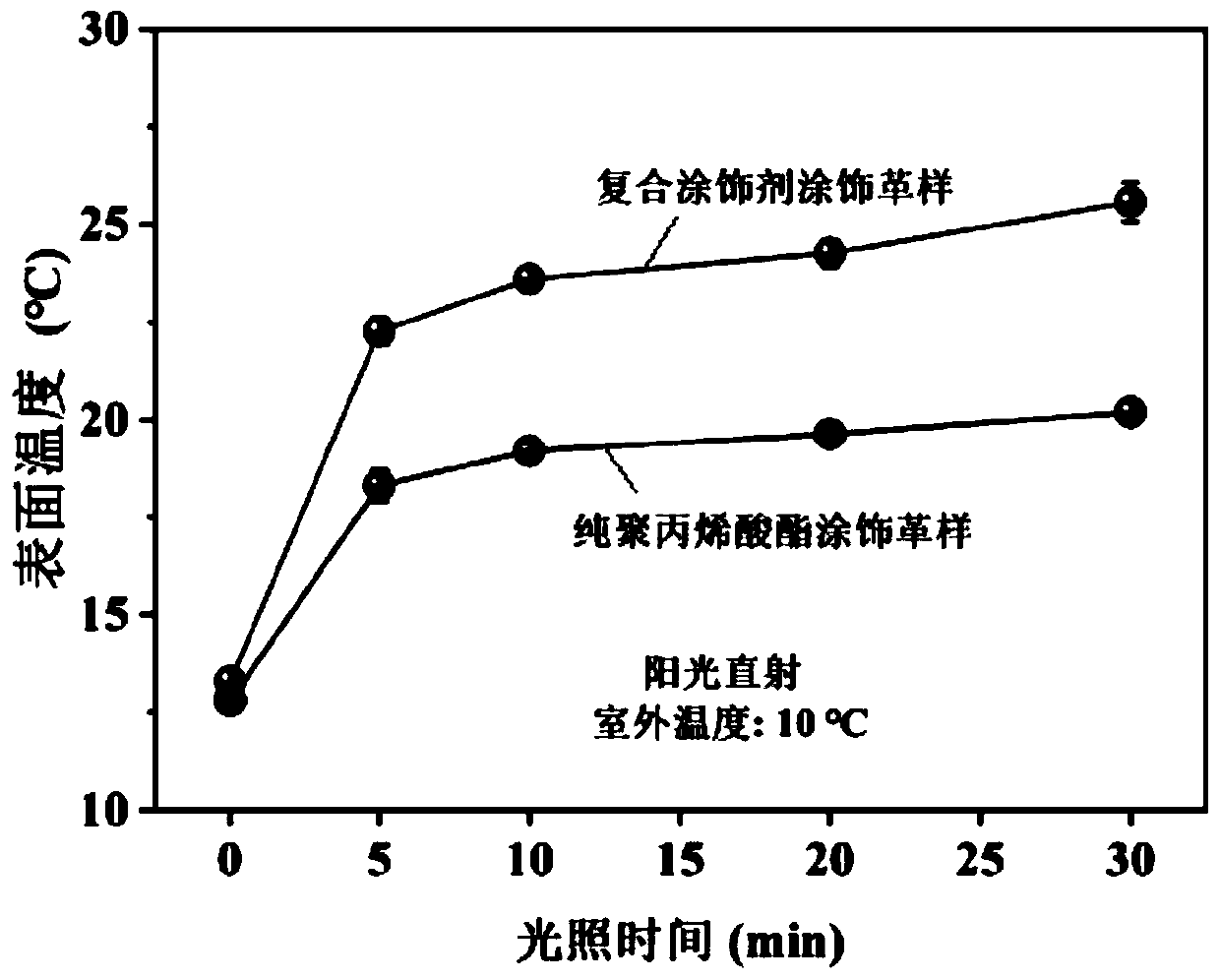

[0036] (1) Under the action of 300W water bath ultrasonic waves, 0.15g two-dimensional Ti 3 C 2 Nanosheets and 0.5g of polyacrylate thickener PTF are added to 100g of anionic polyacrylate emulsion Yanbang 141 with a solid content of 37wt% (that is, the solid mass in anionic polyacrylate emulsion Yanbang 141 is 37g), Stir for 10 min at a stirring speed of 300 rpm to obtain a gray-green photothermal heat preservation leather finishing agent. Among them, Ti 3 C 2 The dosage is 0.4% of the solid mass in the anionic polyacrylate emulsion Yanbang 141.

[0037] (2) Spray the photothermal heat preservation type leather finishing agent on the leather, and the sizing amount is 30g / m 2 , and put the finished leather sample in a 110-degree oven to dry for 3 minutes, then take it out, and put the finished leather sample under direct sunlight outdoors at an outdoor temperature of 10°C.

[0038] Such as figure 1 As shown, only 30 minutes of light in the winter sun, the surface temperat...

Embodiment 2

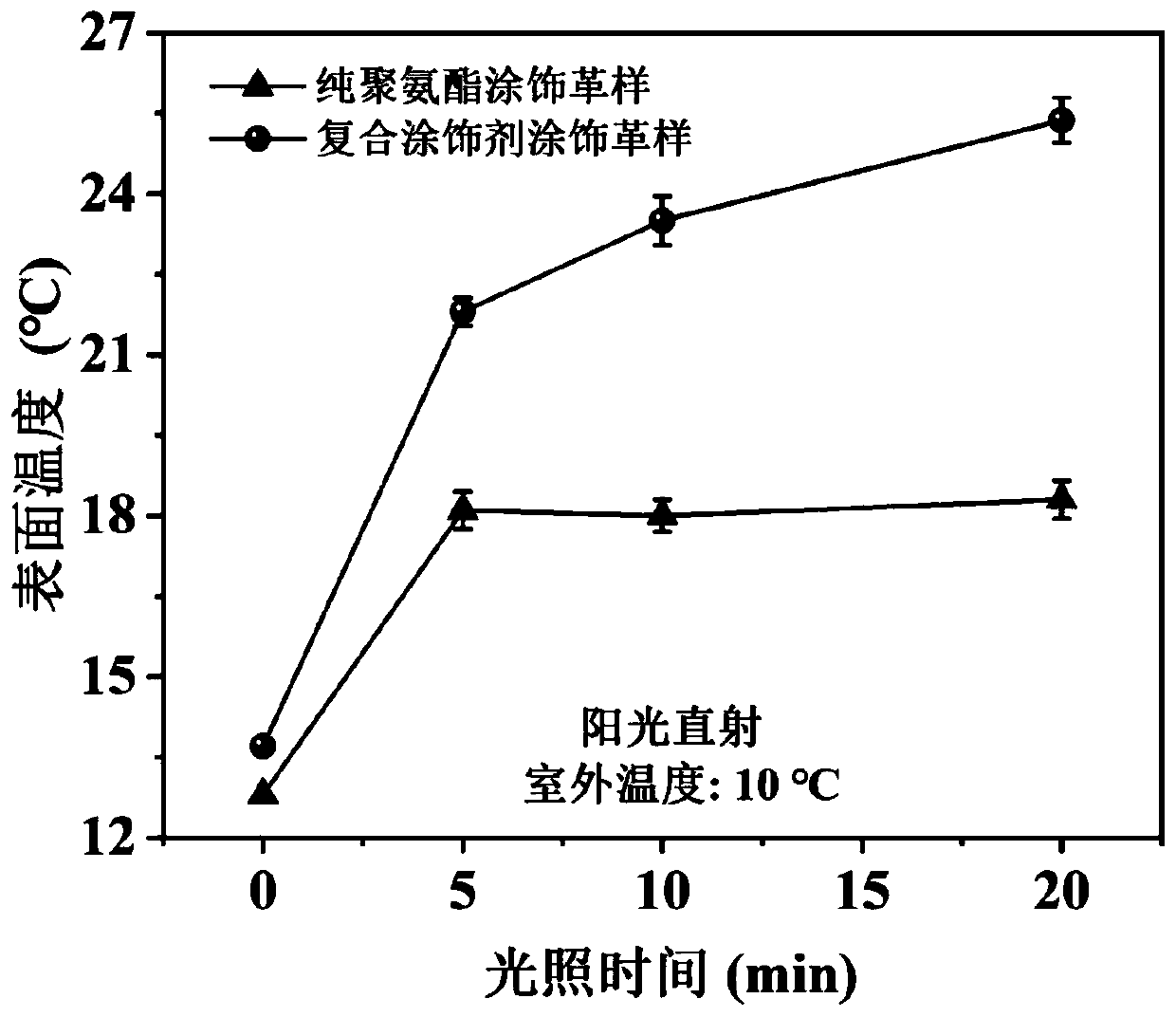

[0041] (1) Under the action of ultrasonic waves in a water bath of 200W, the polyurethane thickener RHEOVIS PU1191 of 0.3g polydopamine nanoparticles and 0.1g is added to 100g of solid content in the anionic polyurethane emulsion Leasys 3102 of 35wt%, then at a stirring speed of Stir at 200 rpm for 20 minutes to obtain a gray photothermal heat preservation type leather finishing agent emulsion. Wherein, the dosage of polydopamine nanoparticles is 0.86% of the solid mass in the anionic polyurethane emulsion Leasys 3102.

[0042](2) Spray the photothermal heat preservation type leather finishing agent on the leather, and the sizing amount is 30g / m 2 , and put the finished leather sample in a 110-degree oven to dry for 3 minutes, then take it out, and put the finished leather sample under direct sunlight outdoors at an outdoor temperature of 10°C.

[0043] Such as figure 2 As shown, only 20 minutes of light in the winter sun, the surface temperature of the leather sample coate...

Embodiment 3

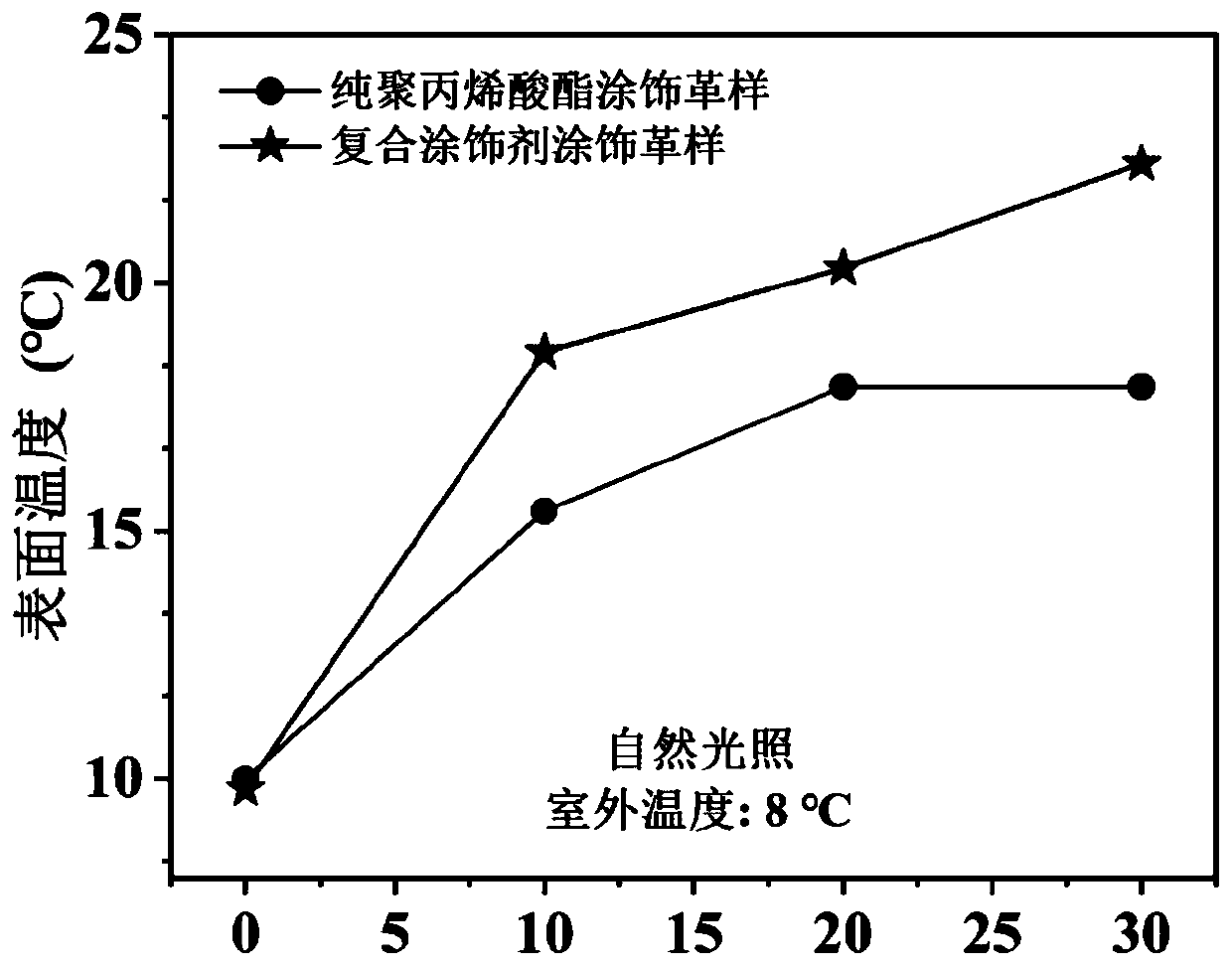

[0045] (1) Under the action of 180W water bath ultrasonic waves, 0.05g of plasma gold nanoparticles and 0.5g of cellulose thickener hydroxyethyl cellulose HEC were added to 100g of anionic polyacrylate emulsion MageAR with a solid content of 35wt%. In -103, at a stirring speed of 300 rpm, stir for 30 minutes to obtain a brown photothermal heat preservation type leather finishing agent emulsion. Wherein, the amount of plasma gold nanoparticles is 0.143% of the solid mass in the anionic polyacrylate emulsion Mage AR-103.

[0046] (2) Spray the photothermal heat preservation type leather finishing agent on the leather, and the sizing amount is 30g / m 2 , and put the finished leather sample in a 110-degree oven to dry for 3 minutes, then take it out, and put the finished leather sample under direct sunlight outdoors at an outdoor temperature of 8°C.

[0047] Such as image 3 As shown, only 30 minutes of light under the winter sun, the surface temperature of the leather sample coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com